3D printing Titanium guide: how to improve your production

Posted By Kat Plewa on Nov 20, 2019 | 0 comments

Maybe you’ve heard about metal 3D printing, but did you know that you can actually use Titanium, one of the strongest materials available? It is actually really popular for engineering, medical and even fashion projects. Why did they decide to use Titanium for 3D printing? How did they improve their production? Let’s dig deeper into this topic!

To have a better understanding of why Titanium 3D printing is so interesting and beneficial, let’s have a quick look at the material itself. We will go over the properties of Titanium, and the 3D printing process, followed by the benefits of this material. This summary will help you understand how you can improve your production. Next, we will move on to real examples of putting Titanium’s advantages to use.

Properties

Titanium is especially known for being lightweight and still strong. Lightweight might not be the first thought you have when it comes to metals, but that’s exactly why Titanium stands out. Titanium is also super strong; it’s a material that will produce robust parts that can withstand a lot of stress.

Another quantity of 3D printing Titanium is non-toxicity, which makes it a great candidate for medical applications. It is also corrosion-resistant, which allows for it to be used in many different projects, from mechanical and engineering projects to dental applications.

Titanium also has an extremely high melting point, and is resistant to oxidation and acids. This 3D printing material can be really beneficial for your project, especially if it requires specific properties.

Printing process

You can 3D print with Titanium in 2 processes: DMLS and EBM. Let’s see how those technologies work and what differs between them.

Direct Metal Laser Sintering (DMLS) 3D printing spreads a layer of Titanium powder, then a laser beam of photons, fuses the material locally. The metal is melted by laser at a temperature between 1510°C to 1600°C. The process repeats.

Electron Beam Melting (EBM), as the name suggests, uses electrons to melt the metal powder. Titanium powder is spread on the preheated bed, layer by layer and then the electron beam fuses the particles accordingly to the 3D model.

Advantages of 3D printing with Titanium

One of the main benefits of 3D printing is the design freedom it brings to your production process. Thanks to AM technologies you can completely rethink and revolutionize the design of your Titanium parts. From hollowing, adding lattice structures to achieving complex geometries.

3D printing Titanium also offers you great quality products. Polished parts will have the same surface finish as produced with traditional means, such as CNC milling or metal injection molding. Additive Manufacturing is also much faster, therefore your production would be quicker without sacrificing the quality of your products.

Titanium itself has an extremely high melting point which is especially advantageous for mechanical engineering projects. Another important property worth mentioning here is the density of Titanium, which is about 60%.

3D printing Titanium is also one of the most bio-compatible metals. Like gold and platinum, Titanium is completely resistant to body fluids. This material truly has amazing characteristics. This is why 3D printing Titanium is widely used for medical applications.

Additionally, you can 3D print complex, but also thin objects with Titanium. The standard layer thickness for Titanium is about 30 µm thin, which opens for you a new door to rethink your design. It is also very accurate, with a precision of ±0.2mm. On top of all of that, thanks to Additive Manufacturing, you can reach a 1 mm size of details.

Applications

Engineering

General Electric (GE) is the industry leader thanks to using the latest technologies. This time they turned to Additive Manufacturing. They radically reduced production and assembly time, as well as brought the weight of an aircraft down, all thanks to titanium 3D printing. How did they do it? With 3D technologies, they were able to completely redesign a part of their engines.

In their new CFM LEAP engines, they used 3D printed fuel nozzles. Before this part was welded from 18 different parts, but with Additive Manufacturing, they were able not only to save time and money but also make 450 kg lighter airplanes, which of course brings more costs down.

Medical

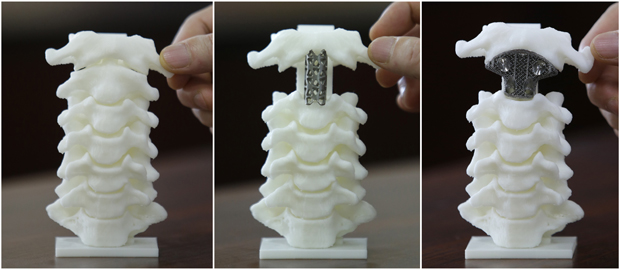

It’s no news that 3D printing technology has been changing the face of the medical industry. And you might also have heard of 3D printed vertebral. But researchers at Peking University brought a new revolution: they not only 3D printed a fully functional vertebral but also implanted it in a patient!

It was received by Minghao, a 12-year-old boy who was diagnosed with cancer after an unfortunate fall during a football game. He suffered from a serious case of a tumor in his spinal cord which had to be removed immediately to prevent it from spreading. Traditional solutions would save the child’s life, but he would be unable to lay his head down for 3 months and was facing pin stabilization.

But Additive Manufacturing gave the doctors a much better option. Thanks to 3D printing technology, the researchers were able to not only produce perfectly fitting vertebral parts, which reduced the risks of surgery and complications, but they also printed in a short amount of time. Most importantly, the recovery time for Minghao was a lot shorter compared to traditional technologies.

Additionally, by using non-toxic Titanium, the possibility of bad reactions by the immune system was low. This implant 3D printed with Titanium has saved the child’s life and also brought new solutions to the medical world.

Fashion

Maybe 3D printing Titanium doesn’t really sound fashionable, but it is actually very interesting for this industry. A Belgian company Hoet Couture is making the most of 3D technologies to produce their stunning eyewear.

Thanks to Additive Manufacturing they were able to achieve a new level of design. Their frames are sleek, stylish, but at the same time lightweight and very strong. The company also claims that its products are eco-friendly and that they keep in mind social and ethical responsibility.

Are you ready to start using 3D printing Titanium?

As you can see, there are numerous applications and benefits of 3D printing Titanium. You can design your models more efficiently, use less material, produce less material waste and manufacture faster. All those aspects also bring your costs down. Of course, without losing the quality of your products. From mechanical engineering, to fashion and medical projects, Additive Manufacturing is bringing the next industrial revolution.

You can actually start 3D printing with Titanium without leaving your house. Sculpteo offers this material on its online 3D printing service. All you have to do is to upload a file or contact us to discuss your project with our 3D printing experts.

Don’t forget to subscribe to our Newsletter and follow us on Facebook to stay up to date with the latest 3D printing news!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook