MIT engineers developed the first 3D printed brain implants

Posted By Jérôme Deschamps on Apr 24, 2020 | 0 comments

Recent developments in 3D Printing have given ground to a wide range of ground-breaking processes that are expected to widen the scope of possibilities in several industries. In this regard, Conductive 3D Printing, a technique that allows printing complex electronic features with electronically conductive materials, is poised to advance IoT and robotics. But what other fields can benefit from this technology?

Professor of mechanical, civil, and environmental engineering Xuanhe Zhao, from MIT, has made the first hydrogel-based conductive neural implants using 3D Printing.

These flexible polymer electrodes could offer viable alternatives to metal-based implants for alleviating symptoms of various diseases such as Parkinson’s and epilepsy.

The challenges of brain implants

The most widespread types of implants used are electrodes based on metal and other hard materials. But, it doesn’t always go smoothly since some of them are designed to be embedded for long periods of time to monitor the brain’s activity.

This organ is indeed fragile, and the immune system is easily triggered by foreign bodies entering the brain. Hence, placing neurological devices can cause inflammation from the glial cells the body generates. These scarring tissues wrap around the devices and may in turn completely deny them from working. Other undesired effects can also be encountered as the brain tissue tends to move within the skull, sometimes causing big implants to slip from the cells they target.

These issues have led scientists to focus on less cumbersome systems, designed with brain-friendly materials.

3D Printed neurological devices

In their search for a material best suited to the brain’s characteristics, Xuanhe Zhao’s team established that the bioelectronic and flexible properties of conducting polymers made them a top-notch solution for brain implants.

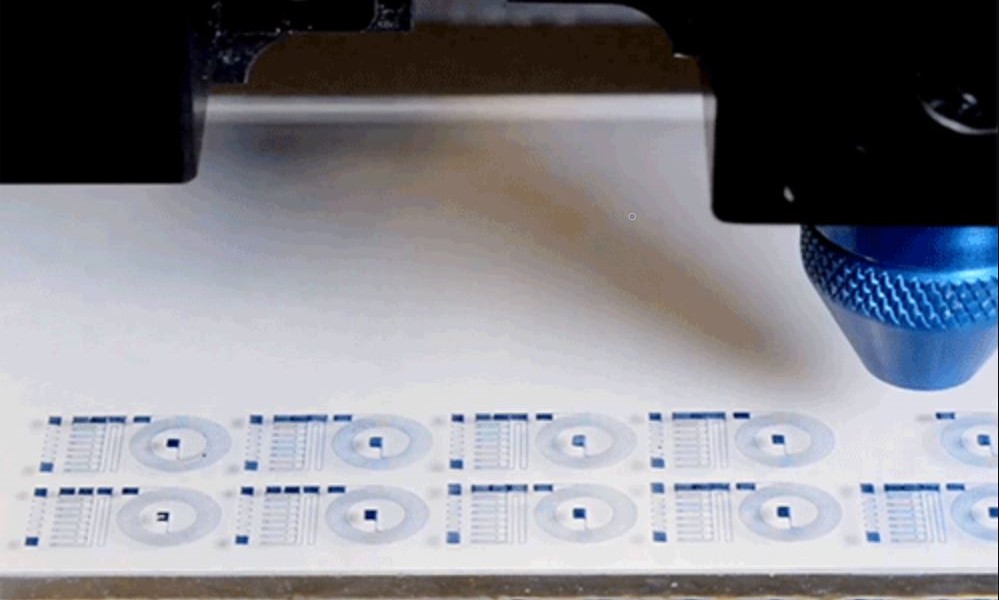

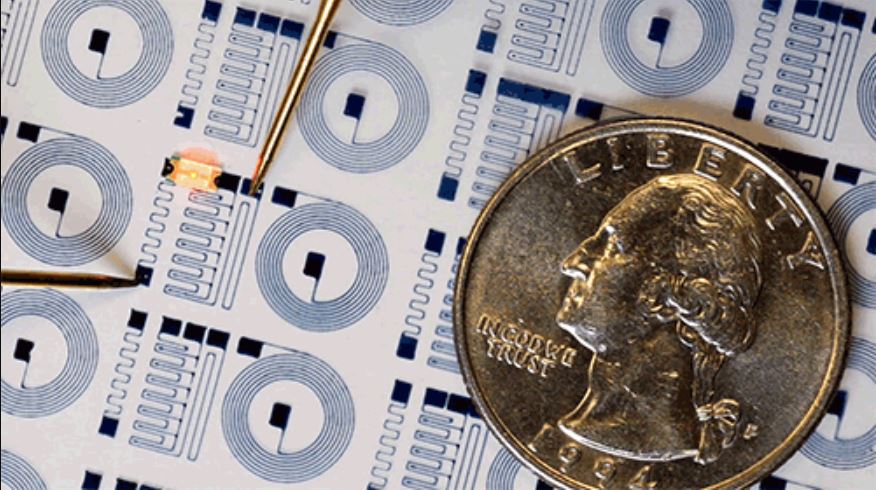

As also stated in their research paper, the cost and resolution limitations of the mainstream processes these polymers rely on prompted the team to look for alternatives. In that sense, 3D Printing turned out to be a fit thanks to its ability to fabricate flexible micro-scale structures.

In order to adapt conductive polymers to 3D printable materials, the research team transformed the liquid polymer solutions into a viscous ink. To achieve this process, the polymers were frozen to remove water so that only nanofibres would remain. After being dried, these elements that allow electrical charges to flow were mixed with an organic solvent. Once a suitable concentration balance was found, the team obtained an electronically conductive hydrogel suitable for 3D printers. The research team then demonstrated the success of this polymer by implanting an electrode they made in the brain of a mouse.

Credit: MIT

Other than avoiding the build-up of scar tissue, using hydrogel-based implants is expected to achieve better results than standard ones. Unlike metal implants, polymeric ones can carry electric signals in the form of ions, similar to the way neurons do. On the other hand, making neurological devices using 3D printing will be far more cost and time-efficient than metal implants, which involve costly processes and materials.

This exciting achievement sets 3D Printing at the forefront of medical technology development. You can sign up to our Newsletter to stay up to date with upcoming 3D printing innovations in the medical industry, and elsewhere.

Credit for main image: MIT

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook