This loving grandfather designs and 3D prints his family gifts

Posted By Alexia Toulmet on Sep 17, 2014 | 0 comments

For the past 25 years Jérôme Morin has been making his grandchildren gifts for special occasions. He’s devoted countless hours to scrapbooking, sculpting, modeling, and designing the perfect family gift. When he discovered 3D Printing and Sculpteo’s services, he knew it would be the best choice to produce his new project. Here is his story.

Everyday, there are new people who discover additive manufacturing as a means of production. Here at Sculpteo, we love these kinds of stories. It gives the power back to the people who want to bring their ideas to life. Jérôme Morin’s story is more than just another order: its a heartwarming story about how an 80-year-old grandfather adapted to new technologies to make the best family gift possible.

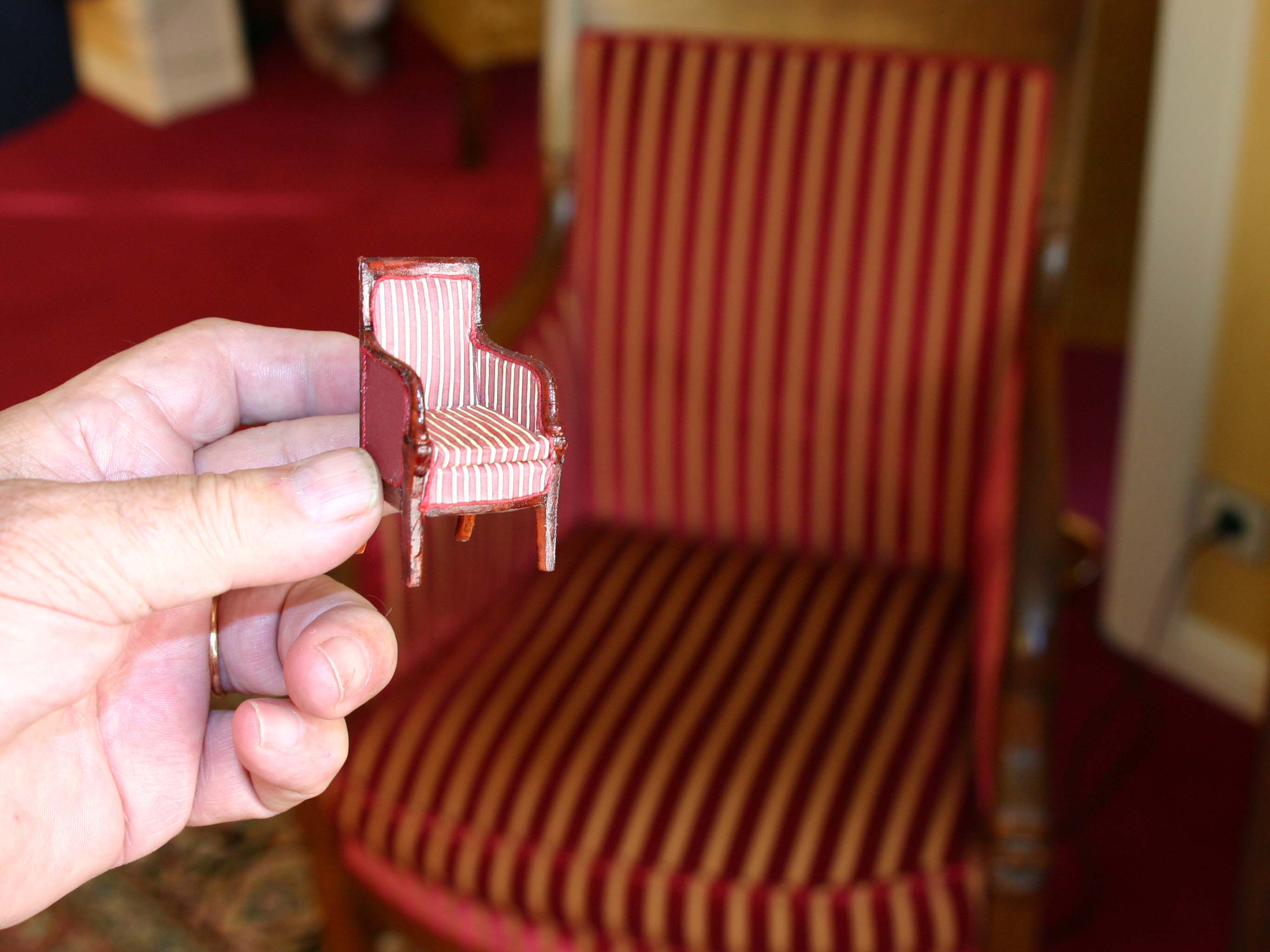

This year, it was his youngest grand son’s turn to have his own miniaturized present for Christmas. Jérôme Morin decided to create a replication of his living-room, at a really small scale. A true challenge when you know how many details his furnitures have.

He actually had several options for his creation.

“ My main concern when I make my miniatures is about fineness and details. I had to choose between laser cutting and 3D Printing.” Discovering Sculpteo’s finishes helped him clear his mind and make his choice.

Using Sculpteo’s plastic helped him miniaturize all the furniture he needed. “I first ordered a Louis XVI chair, in two different sizes. When I received my orders, I was really surprised with the quality of the finishes. Then I ordered more. With some modifications and fimo clay, it enabled me to make four of my armchairs, which actually look great. I plan to 3D print all of the other furnitures”

Our plastic is made from nylon powder, also called polyamid. In order to print a 3D file out of polyamid material, we use the Selective Laser Sintering process (SLS).Our 3D printers, EOS Formiga P100, P110, P395, and P730, use a highly specific laser that sinters thin layers of polyamide powder together one layer at a time. After each round of lasering, the printing bed is lowered and another layer of powder is evenly swept across the top for another round of sintering. This process is repeated at a layer height about 100 µm until the object is completed. Printing precision even reaches 60 µm when you activate Batch Control.

That’s what allowed Jérôme Morin to create his thin and sophisticated shapes, such as for his piano stool.

Sculpteo helped him in his initiative.

“I’m not too bad at using architecture, animation or autocad softwares. But I knew I had to perfectly master 3D modelling skills to get the result I was hoping for, which would take a really long time.”

We offered him to work with our professional 3D designers. Exchanging pictures and ideas, together, they managed to come out with the perfect 3D files for Jérôme Morin’s project.

“Thus Sculpteo gave me the ideal solution in order to create my miniaturized furnitures.”

He intends to offer his miniaturized living room for Christmas. After that, Jérôme Morin plans to create dolls with his children’s and grandchildren’s faces. Nothing can stop him. Here, at Sculpteo, we can’t wait to discover his new ideas.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook