3D Printing Maritime: Military Vessels, Cargo Shipping and more

Posted By Jess Hedstrom on Oct 12, 2015 | 0 comments

Continuing with our series How 3D Printing will Revolutionize your Industry we shift our focus to the Maritime Industry. We will highlight the irreversible effects of 3D printing on an Industry that has been in existence for centuries.

In its 18th annual report on additive manufacturing published last May, Wohlers Associates forecasted that we can expect the 3D printing industry to be worth $4 billion in 2015, and to reach $10.8 billion by 2021. The maritime industry will be among those with the most to gain from 3D printing technology based on the structure of the industry.

Let’s take a closer look to examine the inner workings of this structure; the business of the industry is to export and import goods and services using the waterways as a means for transport; when shipping and naval vessels are travelling across the oceans and something breaks, the ability to immediately repair or manufacture spare items on site has a certain appeal. Today modern cargo ships are required to order and stock large numbers of spare parts and supplies to make sure that they are not caught short when needs arise out at sea. Imagine how 3D printing can change the way this process is managed?

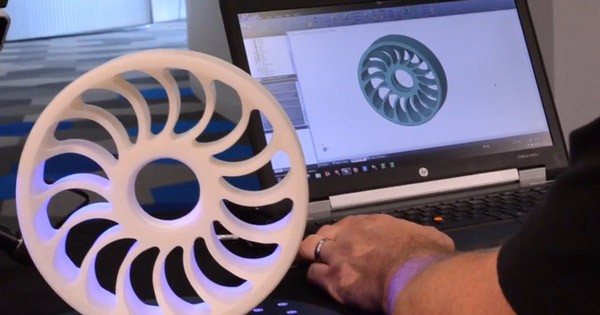

ShipServ describes themselves as “an online marketplace which helps marine and offshore buyers find the best suppliers easily”, and they have decided to rank and publicize the top 20 product category searches by maritime purchasers over last five years. What ShipServ found is that auxiliary engine parts are at the top of the list in terms of spare orders, along with valves, pumps and pipe repair products. From an engineering point of view, a valve could be reproduced with 3D printing without any difficulty as long as it is done accurately and with sufficient strength to hold up to the pressure it would encounter when in use.

Photo Credit: 3Dprint.com

HSVA is a private, self-supporting, not-for-profit organization which provides research and consultancy services within the maritime industry internationally, this organization has developed a deep understanding of intricate problems in ship and offshore hydrodynamics, propeller design and arctic technology.

It is safe to say that this company is on the cutting edge of maritime technology; recently they purchased their own 3D printer for in-house production. With access to a 3D printer HSVA now has the flexibility to respond to customer requests that (prior to the in-house 3D printer) would have required more time. One example is an advanced marine propulsion system known as a “Pod” or the azimuth propulsion drive; the pods are typically a challenge to produce and assemble due to a strut which needs to be removed before accessing the gearbox. HSVA used 3D printing to engineer a redesigned prototype which allowed fast access and easy repair. Michael Neumeier Mechanical Design Engineer at HSVA says:

To traditionally manufacture a prototype ship rudder in wood or plastic is a very skilled and labor intensive job and typically takes up to three weeks to produce; we can produce [3D printed] parts within a day which after cleaning, are ready for final assembly

Hans Oxvang Mortensen is the senior manager at MAN Diesel & Turbo, a manufacturer of some of the systems and spare parts that are being used in the industry today. Mr Mortensen’s company already has experience with 3D printing technology, having used such systems in the past as part of his company’s production operations.

“We have invested in 3D printing for the last year and half,” Mr Mortensen said. “The 3D printers are mainly used for design purposes – that means identifying design details and visualising design elements.” For example, MAN has already 3D printed the prototype of a water mist catcher and installed it on a test engine for evaluation purposes. “Normally we would manufacture this in various forms of steel or iron,” said Mr Mortensen. “But in this case, we manufactured it on our 3D printer as a plastic component. This worked very well for our testing.” Mr. Mortensen notes that using this technique saved the company “a lot of money” compared with creating the prototype in steel and iron, evaluating the cost difference in this case to be in the region of €5,000.

Maritime 3D printing for Military uses

The US Marine Corps Expeditionary Logistics Wargame is an annual event where Marine Corps planners test out the latest technologies to enhance the Corps’ logistics and supply chain response capabilities.

Battle damage requires military hardware to be decommissioned and removed from the theater where it can undergo extended and sometimes costly servicing. But the USMC is now hoping to understand how 3D printing can allow field engineers to scan and print equipment on site.

Marine Corps engineers plan to explore 3D Systems’ advanced 3D scanning and printing tools to rapidly replace damaged parts in the field. Vice Admiral Philip H Cullom, Deputy Chief of Naval Operations (CNO) for Fleet Readiness and Logistics with the U.S. Navy, says 3D printing will be a lynchpin for the armed forces in the field as the technology matures. “It’s my strong belief that 3D printing and advanced manufacturing are breakthrough technologies for our maintenance and logistics functions of the future,” Cullom said and included:

We can gain new capabilities to make rapid repairs, print tools and parts where and when they are needed, carry fewer spares and, ultimately, transform our maritime maintenance and logistics supply chain.

The royal army plans to use 3D printed unmanned ships by 2030

Britain’s navy could be using a fleet of unmanned surface and underwater vessels and small 3D-printed ships within 15 years, according to a report from the former government defense-research laboratory, Qinetiq Group Plc. 3D printing a craft up to 15-meters (50 feet) long and formed from layers of metal, plastic powder or graphene would permit cheaper and quicker production, according to the Global Marine Technology Trends 2030 report. “What we really need to be doing is more experimentation, finding out what’s possible,” Iain Kennedy, Qinetiq’s head of maritime business development, said in an interview.

The Royal Navy is already evaluating unmanned sub-surface torpedo-shaped vessels for use in locating and destroying mines, Kennedy said. Qinetiq is also testing communications between unmanned surface ships, underwater vessels and aerial vehicles that could one day undertake autonomous missions after being released from a manned naval vessel he said. Inmarsat Plc said Tuesday it would provide satellite links to a 6.6 million-euro ($7.4 million) project led by Rolls-Royce Holdings Plc for the development of ships controlled from shore.

Britain is collecting submissions ahead of a strategic defense and security review as the government seeks to shave 20 billion pounds from public spending over the next four years. Bloomberg Business reports that this is not too far off in the future because the Royal Navy is already trying to locate and destroy mines with “unmanned sub-surface torpedo-shaped vessels.” Up to 50-foot-long 3D printed metal and plastic craft would permit cheaper and quicker production, and Navies could do on-site at-sea 3D printing of mission-critical equipment. 3D printing has also been explored as an excellent potential technology for disaster relief sites for the same reason it applies to the military and outer space. In time-critical situations, on-site production is by far the way to go. It will be overwhelming to watch militaries apply 3D printing to move into new territory, but at least we know more concisely what to expect from the (not too distant) future.

For your 3D printing repair, re-engineering, or spare parts needs Sculpteo would be happy to supply you with prototypes and final parts for any 3D printing maritime projects that you see on the horizon. Just click here to find out more.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook