3D printing for the Chemical Industry

Posted By Claire Chabaud on Oct 28, 2015 | 0 comments

What will be the impact of 3D printing in the Chemical industry?

The Chemical industry consists of the companies that produce industrial chemicals as raw materials like, oil, natural gas, and water converted into more than 70,000 different products. This industry has a high financial investment every year, with $59 billion invested in R&D in 2014, which leads to breakthrough innovations. These innovations mainly concern molecular synthesis and new processes to transform matter. To this end, 3D printing just brought new disruptive solutions to make the chemistry go even further!

- 3D printed reactionware for Chemical Syntheses or Chemistry on demand

- Customized and more accessible chemistry

- When Chemical technique improves the speed of 3D printing

- What is next ? 4D printing is coming.

- Everyday 3D printed Lab tool

-

3D printed reactionware for Chemical Syntheses or the Chemistry on demand

First of all, what is a reactionware? No spelling mistake here, this is the name of the custom-built laboratory containers that test chemical reactions because the reagents are built into the container materials. As a matter of fact such containers can be fabricated with low-cost 3D printers as shown by Lee Cronin, professor at the university of Glasgow.

Usually, the laboratory equipment used to do chemical synthesis is expensive, complex to use and often represent an obstacle in the research progress. Whereas with the reactionware, the equipment can be 3D printed at an affordable cost and allows to simplify the process of synthesis as the reagents are already part of the material. That’s precisely why Lee Cronin and his team end up using 3D printing given that “this approach constitutes a cheap, automated, and reconfigurable chemical discovery platform that makes techniques from chemical engineering accessible to typical synthetic laboratories”.

So far, Lee Cronin managed to do multi-step organic synthesis with his 3D printed reactionware and a number of reliable and robust miniaturized fluidic reactors for organic chemical syntheses and materials processes, printed in few hours with inexpensive materials.

In comparison with classic laboratory equipment, reactionware allows more financial independence and a new opportunity to realize chemical synthesis. Moreover, it paves the way for more accessible chemical research.

If you want to get inspired by this project, do not hesitate to watch the TED talk of Lee Cronin.

How will this innovation impact your job in the future?

First, the process to create synthesis could be simplified by removing the process of trial and error to get the reaction working thanks to the system of integrated reagents.

Secondly, this innovation could simplify the process of reproducing a work already existing. Indeed, a chemical ink set can be created and directly used with the downloaded design of the apparatus. This way the reaction can be more automated simplifying the research process.

This automation can lead to deeper changes in the medical industry. For instance, sets including inks and designs could be directly shipped or dialed up by a doctor in developing countries.

If you want to follow the last update about Cronin’s project, have a look to his website

-

Customized and more accessible chemistry

The synthesis of small molecules is a key topic in chemistry. They are organic compounds with very low molecular weight (<900 daltons). Their main purpose is to regulate the biological process. Then, the synthesis of this small molecules can for example create drugs.

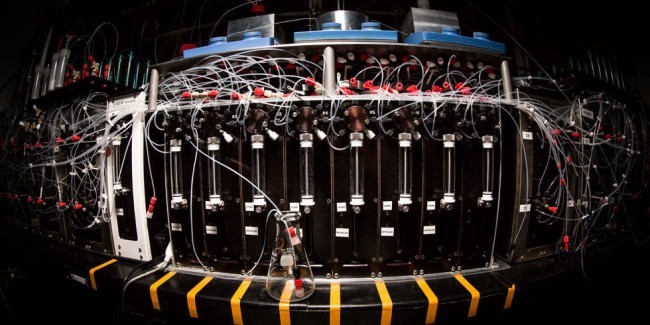

Martin Burke, who heads up Burke Laboratories is a specialist in small molecules synthesis. With his team he created a molecule-making machine, a first in the chemical industry. That is to say, that the machine is able to produce automated chemical synthesis. The process used in this machine could be described as a 3D printer for chemicals.

The main idea hiding behind this innovation is a desire for democratization, Burke explained that he “wanted to take a very complex process, chemical synthesis, and make it simple”. This simple aspect is key to their project because according to them, it is the base on which knowledge can be spread and shared with everyone.

“Simplicity enables automation, which, in turn, can broadly enable discovery and bring the substantial power of making molecules to non-specialists.”

Above, there is a photograph of the machine. Astonishing, isn’t it? Let us explain you how does this complex assembly work.

First, it breaks down very complex molecules into their basic chemical building blocks. Despite the fact that the chemical blocks are totally different from one another, they all share the same connectors. This means that despite their different nature, they can be reassembled , which enables the mix of new chemical structures.

Secondly, the machine use a catch-and-release method to automate the process of connection between the building blocks, while it releases the byproducts of each chemical reaction.

Then, you get the result of the chemical synthesis based on chemical building blocks technique!

This innovation matters as a new way to overcome the limits of synthesis in the current scientist research. Not only it simplifies the chemical mixing and broaden the possibilities of assembly but also, as pointed out by M. Burke “A lot of great medicines have not been discovered yet because of this synthesis bottleneck “. Let’s hope that this disruptive innovation will help to discover new vital medical medicines.

This printer will be developed now by REVOLUTION Medicines, Inc.

How will this innovation revolutionize your job in the future?

First, this project also leads to the idea of chemistry on demand. Except that with the logic of block assembly, the idea there is to broaden the scope of research, by multiplying the possibilities of blending.

Secondly, thanks to the simplified process, more people could have access to this knowledge, and work with the molecules without being limited by synthesis issues or lack of financial means. Ultimately this printer can be used to help bring democracy to science, and allow people with less research funding easier access to traditionally expensive equipment.

If you want to discover more of M. Burke’s vision, do not hesitate to listen to him in this short video.

-

When Chemical technique improves the speed of 3D printing

Chemistry is all about the morphing of materials into another form. This aspect is precisely one of the key challenges of the development of 3D printing: how to create new materials to use with the additive manufacturing process? This matter is important in order to broaden the possibilities of uses but also to go beyond the current limits of 3D printing.

Joseph DeSimone is an American chemist, who asked a striking question in TED talk last april: What if 3D printing was 100 times faster? In order to better understand why this question is important, you can have a look to his talk on the video below.

With the classic layer by layer processes, as FDM, Polyjet, DMLS or SLS technologies, and the current available materials this questions might have found no realistic answer. Indeed, the layer deposition might get faster in the future, but it’s unlikely to get 100 times faster based on current printing techniques. Yet, chemistry found how to go beyond the limits of these technologies by thinking a new way to morph a material into a final object.

Carbon3D, founded by Joseph DeSimone, is the fastest 3D printer on the market. Shining ultraviolet rays up into a bath of liquid resin and the UV light cures the resin. Then, the partial product is pulled upwards one notch to repeat the process for the next layer below.

Here is a video to better understand how it works, be attentive, it goes very fast!

This printer is a telltale example to show how the 3D printing industry and the Chemistry industry are linked.

How will this innovation impact your job in the future?

This printing technology is the first to suggest that 3D printing could be an actual immediate process of creation. Sure, the current delays (few hours) are already short, but this speed suggests that from the idea to the product there would be no entrave. Sure the materials are limited for the moment, but when Chemical research will go further the possibilities will be multiples.

-

What is next ? 4D printing is coming.

We are talking a lot about the impact of 3D printing on the Chemical industry, but this is not a one-way relationship. Actually, chemistry is improving a lot of 3D printing technologies and even preparing its future by making 4D printing possible.

Developed by Self-assembly lab of MIT, 4D printing uses programmable materials that are able to change shape without complex stimulation. The “4” came from the addition of a new variable : the time. Meaning that with the time, the shape of the structure will change.

The researchers illustrated this technology with a Self-Folding Protein. Hold you breath, here there is an example of this technology.

4D Printing: Self-Folding Protein from Self-Assembly Lab, MIT on Vimeo.

If you are curious about this technology, you can discover more on our article about 4D printing. You will find a lot of information on the progress made on 4D printing and the amazing results the MIT researchers found!

-

Everyday 3D printed Lab tool

Besides these important innovations in the chemical industry, 3D printing can also help you in your daily work. For instance at the imperial College London, a PhD student, James Bannock, used 3D printing to save time during his research. He switched to 3D printing because he “can make parts that would otherwise be impossible or unnecessarily time consuming […] and it is especially useful when multiples of the same component are needed’.

He 3D printed a custom built multi-angle light scattering instrument, to determine the molecular weight of polymers.

At Sculpteo, we participate in a similar project with OpenQCM. Which is a scientific instrument whose core is a quartz crystal microbalance, that is a highly sensitive device for weighing mass at molecular scale. It is capable of measuring mass deposition down to the 1 billionth gram. It has a wide range of applications, from chemical and biological sensing to material science.

If you are interested in learning more about this project or wish to learn more about how we can help you to use 3D printing in your industry, have a look to our Chemical industry dedicated page !

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook