Sculpteo Success Story – Making an impact in electromagnetism

Posted By Claire Chabaud on Nov 18, 2015 | 0 comments

Often 3D printing helps move science forward in the research process. The collaboration between the IMS Laboratory and Sculpteo is a telltale example. Based in Bordeaux, France, the IMS laboratory works on the integration process of materials. With 165 researchers, 140 PhD students and 35 engineers/technicians; due to this mixture of people the research topics tend to be very broad.

Florian Voineau, a PhD researcher, tells us more about the use of 3D printing in his department at IMS, the conception of microwave frequencies system research team. His team is comprised of 15 people working on a means of radio communication with very high frequencies. Usually a normal frequency is between 700 MHz – 2 GHz. A very high frequency implies many dozen of GHz, which means that with higher frequencies more significant throughput can be reach. The structure to guide waves developed to reach such frequency is called a Waveguide, its main objective is to transfer power.

Usually the production of this structure is very costly and standardised. It is produced with machining equipment and requires assembly for the individual parts. Let’s take a look at the inefficiencies of this process.

1. The first flaw in this process is assembly. When the final pieces are assembled together by a joint, the power transfer is reduced because the joint is not always optimal.

2. The second flaw in this process is cost. Producing the part with traditional manufacturing is very costly and standardised. It is difficult to improve the final part as the cost incurred are enormous.

Thus, when Mr. Voineau and his team decided to develop their own waveguide, they looked for a solution to overcome these constraints. . Indeed, to develop this highly customized project, the scientists needed non-traditional, non homogeneous parts. This is how Mr.Voineau had the idea to use Sculpteo’s online 3D printing service, to test the customizable aspect of the additive manufacturing.

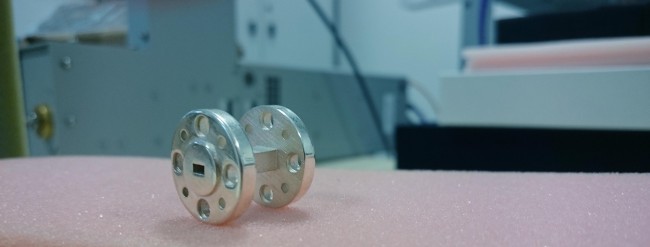

The part they 3D printed is aimed to the guidance of radio waves. Then they requested their 3D printed parts in mirror polished silver to increase the accuracy and precision of their end product. At the moment, they are running tests on a standard model ( WR12) with their Sculpteo 3D printed parts. They were really satisfied with their results and intend to move forward on their research with this technology to develop new solutions for the wave guidance.

This 3D printed piece has a rectangular cavity inside which allows the radio waves to spread with the reflection on the metallic wall. This process enables the part to carry more power than the usual cable system, the geometry of the internal part determines the frequencies that spreads. It’s the reason why the surface accuracy is extremely important. If you want to discover more about this process you can check out this page on electromagnetism.

The result of their research could be used in multiple fields; antennae, satellites, radars and even for security purposes.

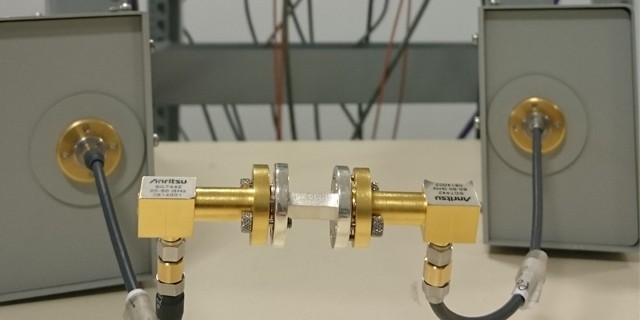

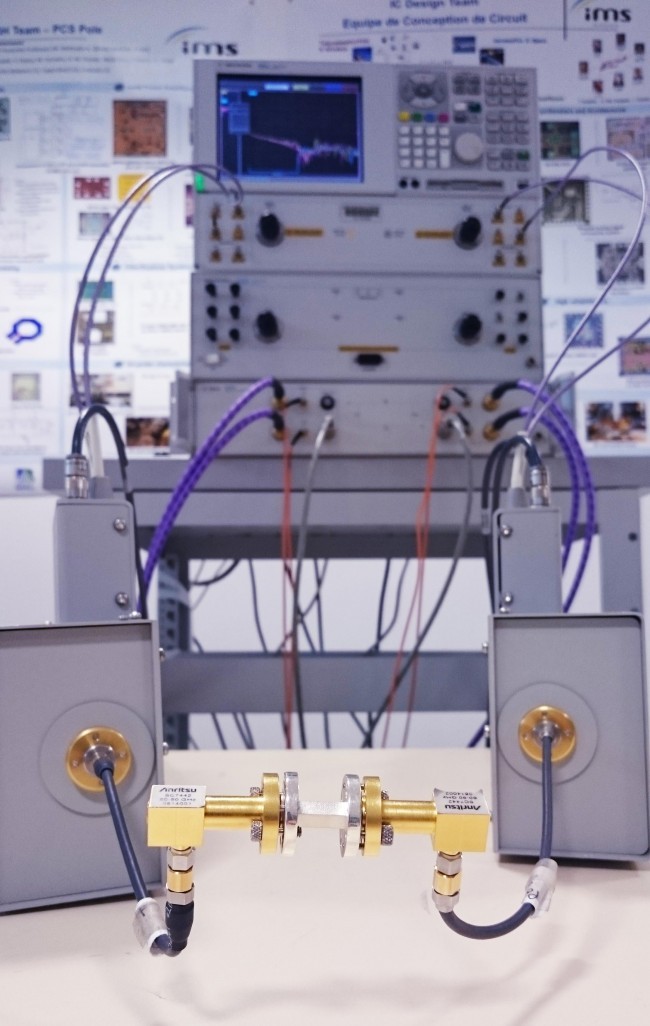

Here is a picture of the measure bench with which they run the test for the part. The golden parts you can see at the end of the arms are the connectors. They connect to the waveguide to test it.

Why is 3D printing the perfect solution for this project?

First, they can 3D print their part in one go, avoiding the negative joint effect, and assembly requirements.

Second, the cost are significantly cut compared to traditional manufacturing process.

Third, they can design customized pieces to improve their current technology

3D printing allows us to move forward on scientific research and it allows us to disrupt very different industries. We hope that the research of the IMS Laboratory with the help of our technology will succeed and drive innovations in the electromagnetic sector!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook