New Material Available: Binder Jetting Stainless Steel for 3D Printing

Posted By Hilmiyati Kusnadi on May 10, 2017 | 0 comments

At Sculpteo, our main focus is to provide the best online 3D printing service. That’s why we regularly offer you new materials and technologies. After Glass-Filled Nylon, we proudly present you a new material: Stainless Steel 420SS/BR using the Binder Jetting technology.

Today we introduce this new material to you, the technology used, its application and tips on how to design your 3D model with Binder Jetting Stainless Steel material.

About Binder Jetting Stainless Steel

The Binder Jetting Stainless Steel material is made from a fine stainless steel 420 powder. The material is composed of 60% of stainless steel and 40% of bronze since, during the 3D printing process, the material is infiltrated with bronze.

What is Binder Jetting?

The metal binder jetting technology was developed by ExOne. It is an additive manufacturing method that creates parts with a binding agent. During the printing process using M-Flex printer, the liquid binding agent is deposited on the metal powder material, layer by layer, until it forms the model that you want. When each layer is deposited, the powder is slightly cured for solidification.

Once the 3D printing is done, the build box is removed from the printer and loaded into the curing oven. When the process is over, the parts are carefully extracted from the build box. The excess of powder is removed with brushes and air blowers.

The next step is the infiltration process, where the parts are placed on a runner into a crucible. Bronze powder is distributed on a side of the crucible which is then placed into a pressurized furnace. This furnace process melts the bronze powder and infiltrates the runner and the attached parts.

When the finished parts are removed from the furnace, they are separated from the runners to be cleaned and bead blasted in order to remove the remaining powder. The parts are now available to be shipped or finished according to your choice.

You can refer to our technology page to learn more about the Binder Jetting process.

Colors and Finishes available for the Binder Jetting Stainless Steel 3D printing material

The Binder Jetting Stainless Steel is available in two colors: Gold and Nickel Plated. However, the plating is purely decorative. It can wear off depending on the use of the 3D printed element, especially if it is used very frequently.

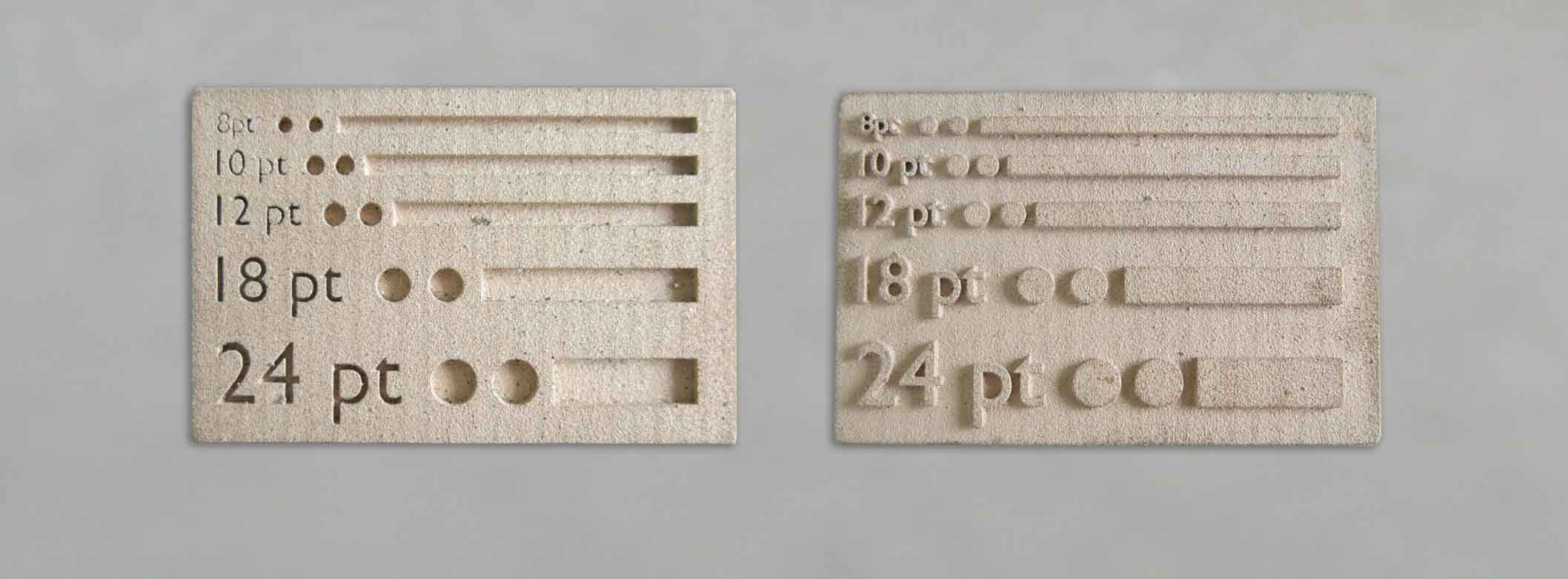

We also offer you two types of finishing options: Raw and Polished. The 3D printed object with raw finishing will be sandblasted but not polished. The surface will remain rough, but it is the most economical option. If you choose the Polished option, the object will be polished using mechanical polishing. The object will be smoother to touch but layer will still be visible, particularly on rounded objects.

One thing that you need to take into account is that the plating and polishing processes introduce a size restriction. In other words, not all designs can be polished or plated. Plating and polishing options are not available if you create wire-framed parts, parts that are fragile, thin-walled parts or large flat parts. When uploading your design, we will give you more information regarding the availability of our finishing option.

What are the benefits and application of the Binder Jetting Stainless Steel?

Metal Binder Jetting is proven to be the less expensive 3D printing technology compared to the other metal 3D printing technologies or even the traditional manufacturing techniques. The Binder Jetting technology allows high customization. Thus, you can create a complex and highly detailed 3D model with fast production time.

Our Stainless Steel 420SS/BR 3D printed with Binder Jetting has great aesthetic properties. It is perfect to 3D print jewelry, decorative objects with fine details and ornamental parts. However, it is not suited for the mechanical parts as it cannot handle excessive loads and stress like our DMLS stainless steel.

What about the shipping delay?

When you upload your 3D file on our site, our platform calculates the cost of your 3D printing automatically, based on the options chosen (size, batch control, hollowing feature, etc) as well as the estimated shipping time.

Our Binder Jetting Stainless Steel can be shipped worldwide, in approximately 16 days. Moreover, the Plating Gold or Nickel will need an extended processing time of 2 to 3 days on average.

Respect the design guidelines to help you 3D print your object

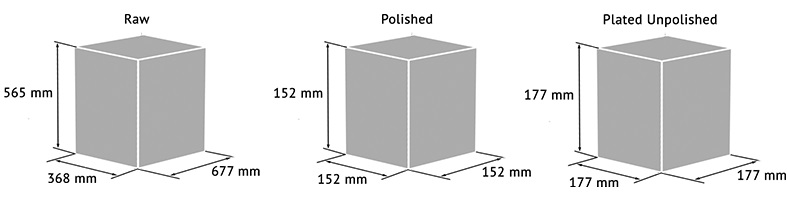

When you design your 3D model in Binder Jetting Stainless Steel, you need to make sure to respect these maximum sizes:

- Maximum size raw and unpolished: 677 x 368 x 565 mm

- Maximum size plated & unpolished: 177.8 x 177.8 x 177.8 mm (7 x 7 x 7 in)

- Maximum size polished: 152.4 x 152.4 x 152.4 mm (6 x 6 x 6 in)

Moreover, the layer thickness of our new material is 100µm. It can be 3D printed with an accuracy of ± 0.1 mm (0.004 in) for parts below 4 cm (15 in) and ± 0.15 mm (0.006 in) for parts above 4 cm (15 in).

Discover more about the design guidelines and the technical specifications. For your information, it is a beta material.

Beside the Binder Jetting Stainless Steel, we also offer other metal for 3D printing, using different technologies such as:

- DMLS: Stainless Steel SS316L and Titanium TiAl64V grade 5

- SLM: Aluminium AlSi7Mg0,6

- Metal Casting: Sterling Silver and Brass material

Get ready to 3D print with our Binder Jetting Stainless Steel material!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook