Metal 3D printers: Everything you need to know

Posted By Marianna Papageorgiou on Oct 31, 2017 | 0 comments

The possibilities that metal 3D printing provides are endless. Many industries like medical, dental, jewelry, aeronautics, aerospace and defense use metal 3D printing for their applications because of the benefits that it brings. You may know that manufacturing metal objects is now possible. Indeed, we have previously introduced you to many topics related to metal 3D printing technologies and metal 3D printing applications, but this time we will tackle with a different topic. Here is a metal 3D printers guide, we will to see what machines currently exist for individual technologies, what metal 3D printers we use for our online 3D printing service at Sculpteo and which are the most promising metal 3D printers to come in the near future in metal printing.

3D printing technologies for different 3D printers

Although there are already many different 3D printing technologies, more develop every year. The reason for the popularity of these manufacturing technologies and thus the variety of the 3D printers is that each technology has its advantages and disadvantages. Each one works differently, has different specifications, uses different materials and processes them in a specific so that it produces different results. If plastic 3D printing is now quite common, metal additive manufacturing is also more and more developed on the market. These 3D printing methods are now seriously competing with traditional manufacturing processes, such as injection molding.

Metal 3D printing technology #1: SLM (Selective Laser Melting)

With Selective Laser Melting 3D printing technology, parts are created additively by fusing metal powder particles together in a full melting process. Unlike DMLS, SLM fully melts the powder, and therefore it needs to reach a higher temperature than this other metal 3D printing technique. Because of this fact, the necessary time for the parts to cool will be longer than for DMLS.

The procedure of metal 3D printing with DMLS goes like this: First, a roller will apply a layer of metal powder, then the laser will sinter the powder according to the 3D file, and the build platform will get down before applying a new layer of powder. The process will be repeated until the final metal object is created. Once it’s finished, the metal part needs to cool down before being extracted.

Metal 3D printing technology #2: DMLS (Direct Metal Laser Sintering)

With this 3D printing technology, the metal 3D printer creates parts additively by sintering fine metal powder particles, to fuse them together locally. The metal melts at a temperature between 1510°C and 1600°C meaning that a high-wattage laser is needed to reach that temperature.

The procedure of metal 3D printing with DMLS goes like this: Firstly, a roller will apply a layer of metal powder. Then the laser will sinter the powder according to the 3D file and the build platform will get down before applying a new layer of powder. The metal part is being created layer by layer, until the final 3D model is shaped. Once it’s finished, the metal part needs to cool down before being extracted.

Metal 3D printing technology #3: Binder Jetting

Binder Jetting is a 3D printing technology that creates parts additively with a binding agent. This 3D printinge process uses a liquid binding agent deposited on the metal powder material, layer by layer, according to your 3D model. When the printing process is complete, the build box is removed from the printer and placed into an oven for curing. Once the process is over, an operator carefully takes the parts from the build box and removes the remaining powder with brushes and air blowers. After this step, the parts are separated from the runners, cleaned and beadblasted to remove the remaining powder.

Metal 3D printers on the market

Metal 3D printers for DMLS technology

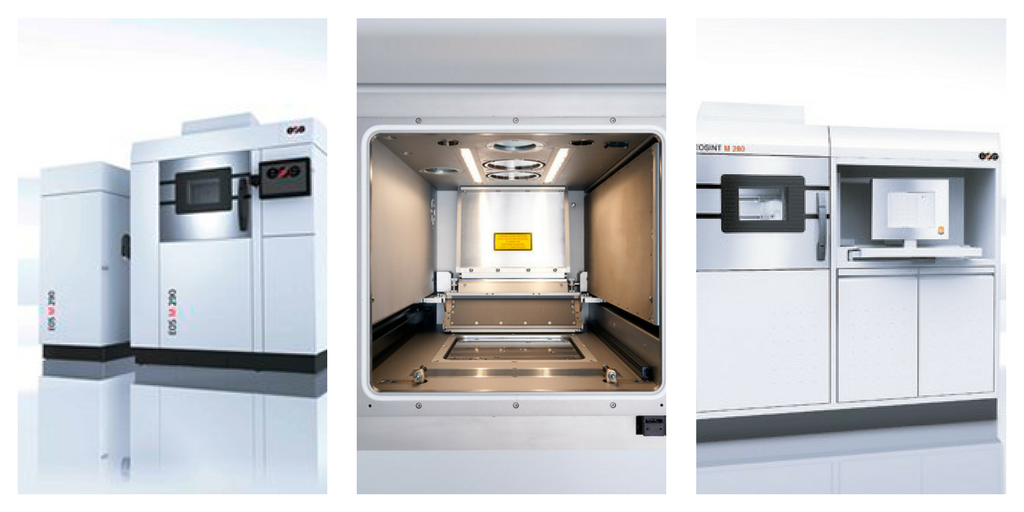

DMLS was developed by the German company EOS. The first DMLS machine, the EOSINT M 250, was launched in 1995. For our DMLS online 3D printing service, we use EOS 3D printers for metal additive manufacturing. Currently EOS offers a series of metal 3D printers, such as: EOS M 100, EOS M 290, EOS M 400, EOS M 400-4, EOS M 280 and EOS M 080.

Among these 3D printers, for our services we use the EOS M 290 and EOS M 280 ones. Let’s take a closer look at them:

EOS M 290 metal 3D Printer

EOS M 290 3D printer has a building volume of 250 x 250 x 325 mm and allows a fast, flexible and cost-effective production of metal parts directly from CAD data. It is a great printer to use in industrial production as it acquires an intuitive user interface, intelligent software concept and improved filter system. It also guarantees excellent detail resolution and high performance every day thanks to its 400-watt fiber laser and its high beam quality of the laser spot.

EOS M 280 metal 3D Printer

EOS M280 is the second 3D printer we use for our DMLS 3D printed parts. It is ideal for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end products. Its high level of productivity and ergonomic useF makes the system ideal for the economical and batch-size optimized additive manufacturing of components throughout all phases of the product lifecycle.

The 3D printer is equipped with a 200 W or 400 W fiber laser which melts fine metal powder and builds up the product layer by layer. With this 3D printer you can create products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts.

Metal 3D printers for SLM technology

SLM 280 metal 3D printer

The first SLM patent was issued in 1995 by the Fraunhofer Institute ILT in Germany. The technology was also developed by F&S, who started collaborating with MCP HEK GmbH, which later became SLM Solutions GmbH, in the early 2000s. For our online SLM online 3D printing service, we use an SLM Solutions metal 3D printer. Currently, SLM Solutions offers a series of metal 3D printers, such as: SLM 500, SLM 280 and SLM 125. Among these, for our services we use the SLM 280 one:

The SLM 280 3D printer has a building volume of 280 x 280 x 365 mm and provides a patented multi-beam technology. During the build process up to two fiber lasers expose the build field via a 3D scan optic system. Depending on how the components are arranged, a 80% higher build rate can be achieved. In addition, the patented bidirectional powder coating helps to reduce the manufacturing time of individually manufactured metal build parts. Thus, the Selective Laser Melting Machine SLM 280 2.0 enables the manufacture of individual metal components based on CAD data for series production and one-off production with individual parameters.

Metal 3D printers for Binder Jetting technology

M-Flex metal 3D printer

The metal binder jetting technology was developed by the company ExOne since 1996. At Sculpteo we are using the M-Flex printer to 3D print your part in metal binder jetting. The M-Flex metal 3D printer is simple to use, as it offers flexibility from prototype to production and prints 10x faster than older 3D printers. It comes with a highly accurate system that provides great design freedom and ability to produce complex geometries without need for special tooling. The ExOne Binder Jetting process is economical and creates functional parts with superior wear characteristics, fast print speeds and no support structures. Also, it enables machine customization for customer-specific metal material requirements.

We invite you to watch the video below that illustrates the way the M-flex metal 3D printer is working:

The best metal 3D printers to come

A few weeks ago we introduced you to the best 3D printers that are coming in 2018.

Now let’s take a closer look at the upcoming metal 3D printers that will totally revolutionize the metal 3D printing industry in the near future.

Metal 3D Printer #1: DM Production System

DM Production System is an affordable metal 3D printer developed by Desktop Metal company and it uses a 3D printing process called Single Pass Jetting. What is really promising about its process is that it is 100 times faster and 20 times cheaper than existing metal 3D printing options. So, the DM Production System metal 3D printer is targeting and addressing mainly the mass manufacturing industry for 3D printed metal parts. This 3D printer will be available at the beginning of 2018, so until then you can have a preview of its potential in the following video

Metal 3D Printer #2: DM Metal Studio

DM Metal Studio is another 3D printer provided by Desktop Metal company. This one though, is not meant to target the mass production for metal 3D printing. DM Metal Studio is a metal 3D printer for domestic use. This is a major breakthrough as metal 3D printing at home is considered to be very difficult because of the extremely high melting temperature needed. This metal 3D printer is working in a similar way to Fused Deposition Modeling (FDM) technology, so that it eliminates the safety concerns and requirements associated with current metal 3D printing procedures. The video below illustrates the way it is working.

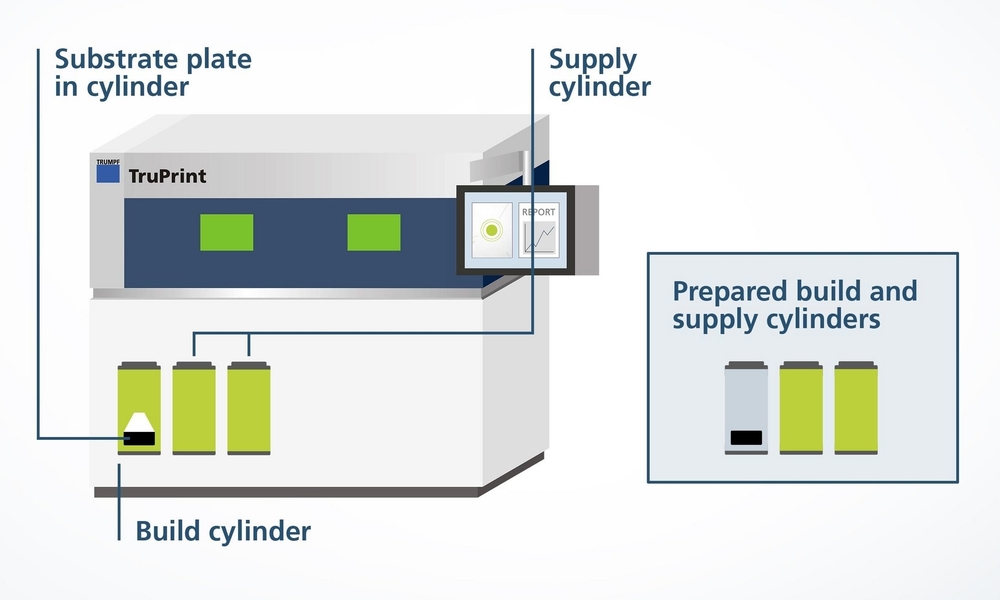

Metal 3D Printer #3: TruPrint 3000

The TruPrint 3000 3D printer is a universal medium-format machine with industrial part and powder management for the series production of complex, metal components using 3D printing. Its key aspects are the large building volume (300 x 400 mm) and its high flexibility geometry of the respective application. It is also meant to optimize the productivity and the machine utilization rate, thanks to its system for fast replaceable supply cylinders and powder management.

Metal 3D printing materials at Sculpteo

According to our year report, the state of 3D printing, metal is the 3rd most used material (28%), fact that shows a big tendency towards the metal 3D printing industry. That’s why through our online 3D printing service, apart from the wide variety of materials we offer you to choose from, we have many metal 3D printing materials as well. You can choose among Aluminum AISi7Mg0,6, Stainless Steel 316L, Titanium 6AI-4V, Steel / Bronze 420SS/BR, Stainless Steel 316, Sterling Silver or Brass.

We hope this article met your expectations about metal printing, metal materials and metal printers. As you can see, metal additive manufacturing is a real alternative to metal injection molding. It will certainly help you to create any the metal object that you will need for your future projects. If you want to continue reading about this topic, we invite you to read our related article about the new 3D printers that will be launched soon.

To read more about the metal 3D printing industry, download our metal 3D printing guide or get some interesting insights about metal 3D printing in our e-book “The state of 3D printing 2017“.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook