Discover 7 of the coolest metal 3D printing applications!

Posted By Amandine Richardot on Jul 19, 2017 | 2 comments

Metal 3D printing is a very promising technology, creating great opportunities for many industries. Using this manufacturing technique, you can produce fully functioning 3D printed parts with great mechanical properties. At Sculpteo, we strongly believe this is a real game-changing technology, and so do our customers. In our 2017 study dedicated to 3D printing, metals ranked as the third most used kind of materials. But what can you actually create with metal 3D printing? What are the real-life applications of this technology? Here are 7 of the coolest ones!

Metal 3D Printing Application n°1: Creating custom-made hearing aids

Sonova, a Swiss company, started using 3D printing to create custom-made hearing aids, using Acrylic. How do they make it? First, they take an impression of the patient’s ear canal by hand, using silicon. Then, the mold is 3D scanned and turned into a 3D model.

They recently succeeded in creating Virto B-Titanium devices, which fit better the patient’s ear and are more resistant. Indeed, hearing aids made with this material are 15 times stronger than Acrylic ones. Moreover, the device is 26% smaller than the average products on the market, being approximately the size of a fingertip, and remaining as performant as other hearing aids.

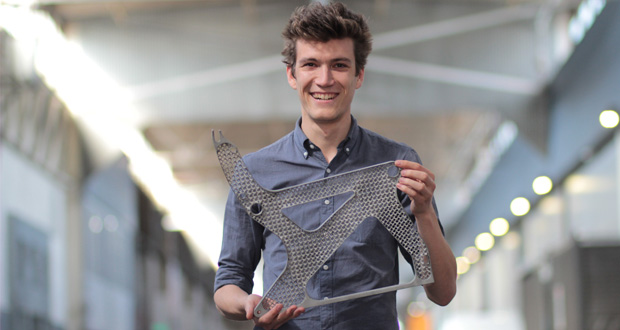

Metal 3D Printing Application n°2: Designing bike handlebars for the Tour de France

The Tour de France is a major cycling event which takes place each year, and that can sometimes be seen as a bit old school. But that would be a mistake to judge it in this way: innovation is coming! Indeed, Pinarello, an Italian company, has used metal 3D printing to create a unique handlebar design for two cyclists: Chris Froome and Geraint Thomas.

Metal 3D printing has been chosen since it allowed to create custom-made designs, with cost and lead time reduction. And it worked! Geraint Thomas won the first race of the event. And Chris Froome is currently leading the Tour, which will end on Sunday, July 23rd.

Did you know that at Sculpteo we already designed a bike using 3D printing? And that our team rode this partly 3D printed bike from Las Vegas to San Francisco? Discover how we created it in these two blog posts!

Metal 3D printing application n°3: Making plane seats

3D printing is a common prototyping and manufacturing technique in the aerospace industry, especially to make their parts lighter. If the plane is lighter, you need less fuel, and thus your costs strongly decline.

A scientist from Autodesk found a new metal 3D printing application using this technology: he created extremely light plane seats. Indeed, this new structure is more than 50% lighter than regular seats (766 grams, versus 1672). How did he do that? Using magnesium, a metal that is lighter than regular aluminum, but that is harder to melt. This new structure is still being tested, but it opens really interesting possibilities for the aerospace industry!

Metal 3D printing application n°4: Creating submarine parts

Metal 3D printing can send you up in the air, but it can also help you dive deep down under the water… in a submarine! Indeed, the International Submarine Engineering (ISE), an engineering company, decided to use 3D printing for one of their projects: a submarine that will be deployed in the Antarctic and that will go down up to 5000 meters under the surface.

They 3D printed a titanium ballast tank, a component which provides stability for the vessel in any water-based vehicle. It holds water and helps the submarine dive and emerge. Using metal 3D printing for this element reduced both production time and costs in a significant way.

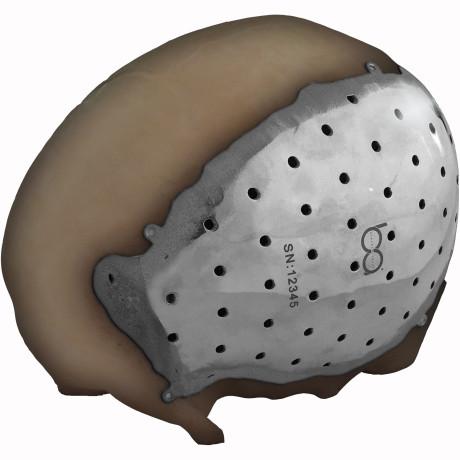

Metal 3D printing application n°5: 3D printing cranial implants

3D printing is contributing a lot to the rapid evolution of facial reconstruction. This extreme challenge requires ongoing innovation to create the best custom-made implants for the patients. Companies such as BioArchitects started using 3D printing to make patient-specific implants to replace hard tissues, 3D printed with a biocompatible titanium.

How is it made? The doctors take an MRI scan of the patient’s head, and the images they obtain are used to 3D print a titanium part that perfectly fits, using the EBM technology (Electron Beam Melting). It is fixed to the patient’s head using self-tapping titanium screws.

Metal 3D printing application n°6: Replacing bones

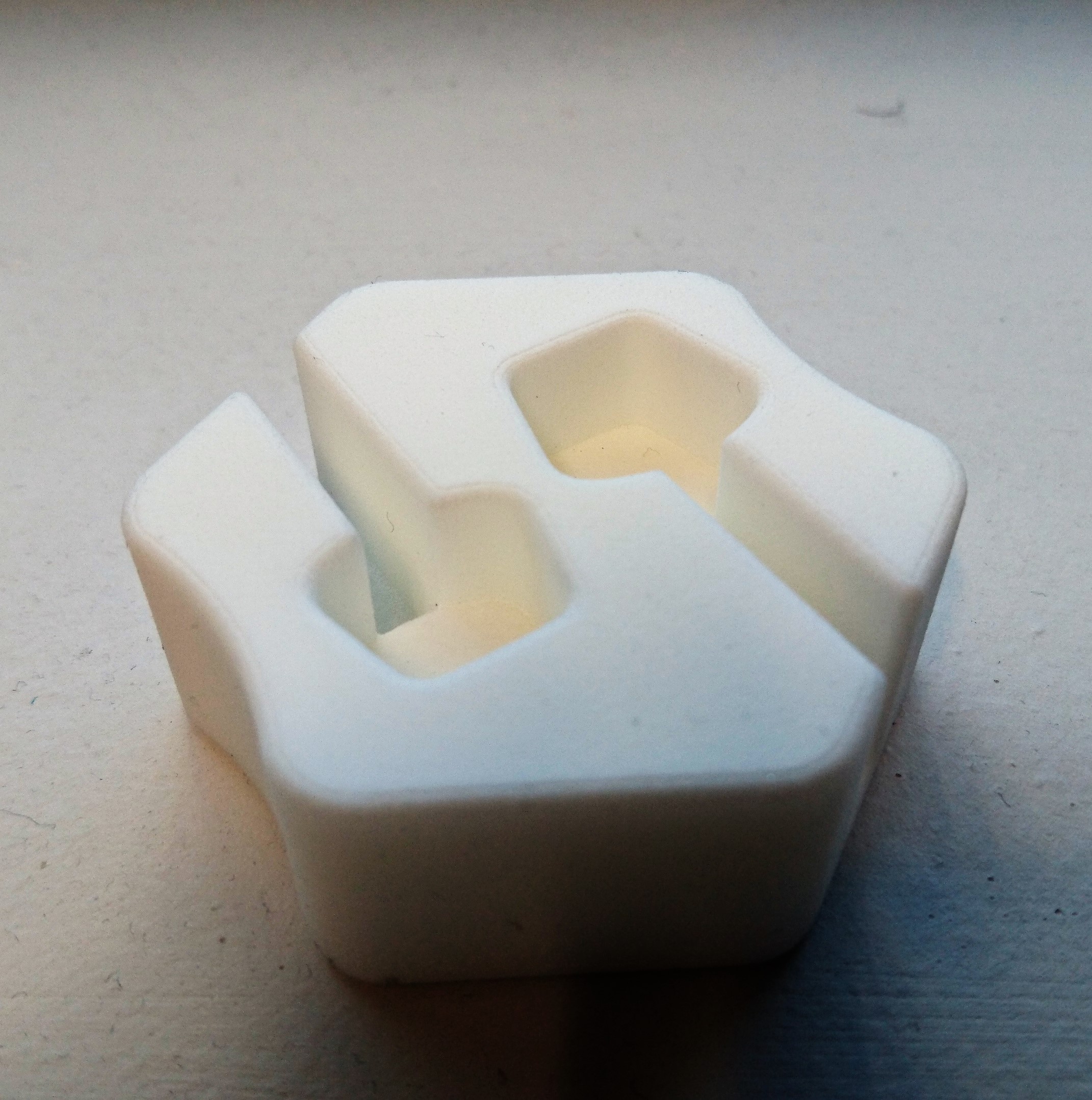

Metal 3D printing can also be used in the medical sector for other purposes than the creation of cranial implants. You can create custom-made elements for a lot of body parts. One of our customers, Spine Vision, uses it to 3D print bone implants for the spine, using both stainless steel and titanium.

Thanks to their products, doctors can treat various pathologies like degeneration, trauma, scoliosis, tumors, etc. Implant range, shape, and size can be modified depending on each patient, in order to make the best implant possible.

Discover their project through this interview we made and learn how they actually use metal 3D printing.

3D Printed Prototype for the cage support, which allows to insert a bone transplant in the implant. Credits: SpineVision

Metal 3D printing application n°7: Designing high-security cylinder locks and keys

Last but not least of these cool metal 3D printing applications: making your door safer! Using this technology, you can 3D print unique high-security cylinder locks and keys. That’s precisely what UrbanAlps, a Swiss company did. They mass produce locks and keys, but they’re all different one from another.

The main benefit of these keys is that they are extremely hard to reproduce, thus highly secure. How come? Most of the mechanical security features are hidden inside of the key, which makes it impossible to scan.

We hope you enjoyed these metal 3D printing applications as much as we did! If you want to use metal 3D printing, it might be for other types of projects. To help you choose which metal 3D printing technology is right for you, discover our blog post “Metal 3D printing: Which technologies for which applications?”

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook