3D Printed Shoes: How Two Fashion Experts See This Revolution

Posted By Amandine Richardot on Nov 22, 2017 | 0 comments

A few weeks ago, Marine Core-Baillais, Deputy CEO of Sculpteo, was invited as a speaker to a Première Vision conference in Paris where she got to talk about 3D printed shoes. Two experts on the topic led this conference: Nathalie Elharrar and Aurélie Besombes, both experts in shoe manufacturing and in the shoe industry. To follow up on this conference, we had a chat with them to synthesize their views and go a bit further on the future of 3D printing for shoes. According to them, this technology definitely is a game changer for the shoe industry. Discover how in this interview.

First, could you introduce yourself to our readers?

Aurélie: I first studied at a fashion and art direction school, but I soon felt I had a need to “make”. So I worked for 4 years with boot manufacturers. Thus, I’m very specialized in shoes. I then got the opportunity to work in China where I did the whole audit of the shoe manufacturing zone of a whole region, to see how we could make the skills evolve, as well as improve quality both in terms of production, of design, and of communications. When I came back to France, I worked mainly with startups on innovation projects around shoes. I’ve been working with Nathalie for one year on multiple shoe-related projects.

Nathalie: On my side, I studied industrial design at the Beaux Arts of Toulouse, and then I learned how to make design and modeling of shoes and leather craft at the AFPIC. I then worked in accessories creation and production for various renowned brands such as Balmain, Michel Klein, Guy Laroche, Mugler and Lagerfeld, both on creative and technical aspects. I then created my own company 12 years ago, with my first brand, Larare. I then created Maison Larare, a consulting and design structure, as well as my second brand Jour Férié Paris.

When did you first discover 3D printing? What did you think of it?

Nathalie: I first discovered 3D printing in 2000. Initially, the first projects left me quite indifferent because they were too tech-oriented, and most of all they were not very realistic solutions to manufacturing products that could be used daily since only extremely uncomfortable shoes could be produced. So my first contact was quite critical, but I was conscious from the beginning that positive evolutions could take place. There was mainly a need for materials that would fit the constraints linked to shoes, and for lower prices.

Aurélie: I discovered 3D printing straight in a shoe prototyping lab. I had already heard about it, but it was my first physical contact. My feedback was more practical: I directly saw there was a strong difficulty to create a 3D model with a sole that would fit well the instep of the foot. So this technology seemed useful for a visual prototype, but not for real use or even for fitting sessions.

Nathalie: To synthesize, 3D printing still had to improve at that time. The 3D printing materials and 3D printing technologies were not right to create real 3D printed shoes.

3D printed shoes: What’s the situation today?

Nathalie: Today, you need to combine different manufacturing techniques to get a satisfying result. Indeed, using only 3D printing doesn’t allow to produce a complete shoe. Several specialized 3D modeling software allow to take into account all of the constraints related to shoes and to create a complete 3D model. You can then 3D print shoes that correspond to a reality. But it won’t be possible to use them in real life, it will be more of a visual prototype. The issue doesn’t really come from the aspect since many material libraries allow to get the desired result, but you still can’t 3D print a material that allows creating 100% of a shoe you can really use: some parts are still very hard to 3D print like the upper part. There mainly are issues with solidity and flexibility.

On the other hand, we saw with some major examples such as Adidas or Phits that it’s possible to 3D print a sole that you can totally use, which allows producing a viable and durable shoe. 3D printing is also very useful to create heels. For instance, that’s what the architect Janne Kyttanen does. He created a whole series of very creative wedge heels, with an upper part made in a traditional way. So this technology is very useful to create components, but not a full shoe yet. For instance, it allows to create important parts that make the whole personality of the shoe and that couldn’t exist without 3D printing.

According to you, what is the most complete 3D printed shoes project?

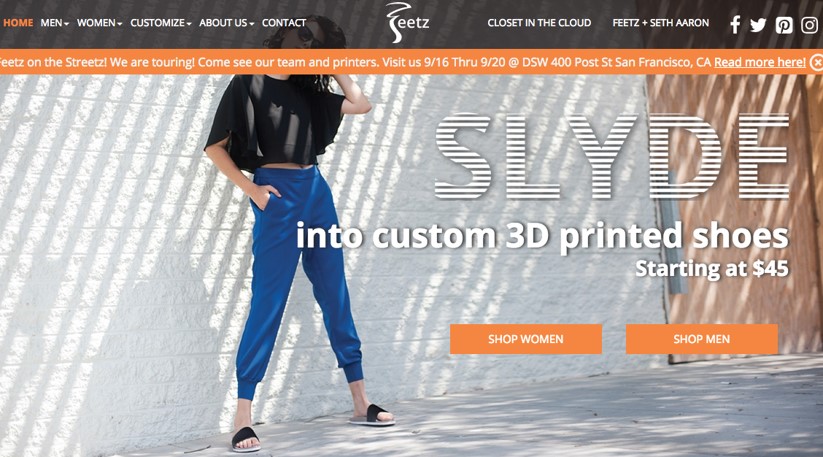

Nathalie: Without a doubt, I would say it’s Feetz. Their patented technology allows creating an upper part with a 3D printed knitted elastic thread. The result is a good durability capacity, and it can be commercialized. In my opinion, that’s the only company who succeeded in turning fully 3D printed shoes into a viable business model.

What’s the added value of shoe 3D printing for brands?

Nathalie: First, it allows to explore new shapes. Right now, it’s also a marketing tool to show that a brand is innovative, but I think this won’t last long since this technology is becoming more mainstream. In some cases, 3D printing also allows developing new types of products.

Aurélie: 3D printing also allows to reduce costs regarding new customer needs such as customization, a key element in today’s fashion but which implies a lot of constraints. The shoe industry didn’t develop yet a type of production that matches this demand. Feetz is here a good example with their 3D scanning app which allows the creation of custom-made shoes.

Nathalie: Indeed, 3D printing allows the rise of a true innovation in business models: you work in a just-in-time logic towards the customer, and you can personalize products. This just-in-time logic and the disappearance of stocks is even pushed further if you work with a 3D printing service such as Sculpteo since you don’t need to invest in 3D printers.

And what’s the added value of shoe 3D printing for customers?

Aurélie: The first major benefit is customization. Customers ask more and more for products that are adapted to their personal needs.

Nathalie: The sustainable and eco-friendly aspect is also a major argument. Indeed, more and more people wish to purchase products without leather and that can be recycled. That’s one of the smartest elements from Feetz: you can send them back your used pair of 3D printed shoes and it will be fused before being recycled in another pair of shoes.

Do you think that 3D printed shoes will be more a project for renowned brands or small designers?

Nathalie: It will mainly be a startup project, but renowned brands will also be very linked to 3D printed shoes. They always invest in the major innovations and then reinterpret it according to their values. For instance, I’m sure that Chanel will be 3D printing shoes or bags in less than 3 years from now, especially since their brand identity is strongly based on pop culture.

Interested in how 3D printed shoes are a true revolution? Read more about it with our related blog posts:

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook