How to optimize your 3D printing cost? Our best tips

Posted By Marianna Papageorgiou on Feb 7, 2018 | 0 comments

One of the main concerns of our customers is the 3D printing cost. Indeed, using the 3D printing technology may be a quite expensive manufacturing choice if you don’t know all the best tips on how to optimize your 3D printing cost.

On the other hand, it is a disruptive technology that aims to democratize the design and manufacturing process, and for this reason we believe that it should be affordable for everyone. That said, in this article we will provide you the best tips for helping you reduce your 3D printing price and still get the best 3D printing result!

Which parameters affect your 3D printing cost?

Your 3D printing cost depends on many factors: the 3D printing material, the 3D printing finish, the size of the 3D model, the layer thickness, the hollowing of your model and the volume that it’s occupying in the 3D printer’s batch, to name a few.

Though, apart from the tools used for the manufacturing procedure, there are many more parameters that are affecting the 3D printing price. One of the most impacting factors has to do with the shipping methods, the special discounts we offer for our frequent customers and for students and many more privileges that are available from time to time through our online 3D printing service. Let’s see in detail the parameters that influence your 3D printing cost and how you can deal with them.

Special offers for reducing your 3D printing price provided by Sculpteo

At Sculpteo, we always strive for providing the best customer experience. Thus, we hope that our customers will keep trusting us for their projects. The following tips will help you organize your next purchases in a smart way in order to minimize the 3D printing cost that is related to shipping or take advantage of special promotional offers.

Free shipping for all orders above 1000 $/€/£

As in all the ordering services, shipping is an additional cost, that in many cases is inevitable. However, Sculpteo offers you the possibility to pay only for the actual production of your 3D parts, eliminating the shipping cost. This great offer comes as a great gift for our customers: for all orders above 1000 $/€/£ we are shipping for free!

Student Reduction Program: Special 3D printing prices for Students

At Sculpteo we’ve always believed that 3D printing can be a great tool for school and college projects and we try to bring Additive Manufacturing closer to education. So, if you are a student you can get a 20% discount on our online 3D Printing service! All you have to do is send an attached copy of your student ID to this email address: [email protected], and shortly after you will receive your unique 20% discount coupon on Sculpteo.com! You can read more about it on this blog post.

Loyalty program: Special prices for our frequent customers

We think that the loyalty of our customers should be rewarded by our 3D Printing service. Thus, we have created “Sculpteo’s Loyalty Program”, which comes with 3 tier rewards:

- If you make 3 orders within 100 days, your next order will be shipped for free!

- If you make 6 orders within 200 days, you’ll get a 12% discount coupon.

- If you make 15 order in a year, you’ll get a 16% discount on your next order.

Shipping mode: Economy

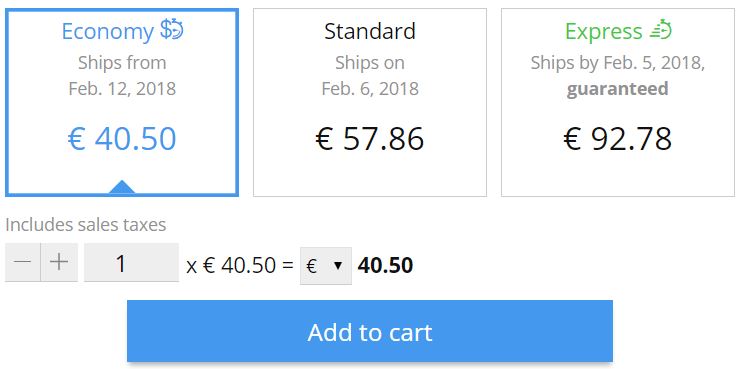

Once you upload your 3D file on our online ordering platform, you will be asked to choose your shipping mode, as indicated in the picture below:

As you can see, there are 3 available modes: The Economy mode, the Standard mode and the Express mode. Among the 3 of them, the “Economy” options is the most affordable one and saves up to 30% on the 3D printing cost. This option is available only for white Nylon PA 12 plastics, printed with the SLS technology, with or without all the finishes we offer. The “Economy” mode only affects the shipping date, meaning that you will receive your order not as early as with the “Standard” or the “Express” mode. Still though, your 3D printing quality is always guaranteed to respect our highest standards.

Tools that reduce your 3D printing cost

Batch control Tool: Reduce the 3D printing price of your series

As a production technique, 3D printing can be more affordable for a big amount of production. As a matter of fact, at Sculpteo’s online 3D printing service, we provide an online tool called “Batch Control”, that is available for orders above 20 pieces. This tool is compatible with powder-based 3D printing technologies, such as SLS, HP MultiJet Fusion and Color Jet. The activation of this tools is linked to the number of units and the material you select, and it helps you to reduce the initial unit 3D printing cost by up to 80%!

Moreover, by using our “Batch Control” tool you get a virtual control of the 3D printer that will process your part. Viewing the volume of the batch, you can organize the 3D printer’s space and benefit from further price reduction. All you have to do is to specify the part orientation of your 3D prints in a customized way, and the 3D printing price will change dynamically. The video below explains how the “Batch Control” tool works:

Hollowing Tool: Hollow properly your 3D models

Another great feature of our online 3D Printing platform is the “Hollowing Tool”, that is also applied on the powder-based 3D printing technologies. As the 3D printing depends on the quantity of the material used, hollowing is a very effective way to reduce the volume of a 3D model and consequently reduce its cost. There are two possible ways to achieve hollowing. Either by using a 3D modeling software and manually modify your 3D model so as to have the less volume possible, or by using our online “Hollowing Tool”. Whichever way you choose, make sure to apply the best tips for successfully hollowing your 3D models that we provided you. If you compare the 3D printing cost of a hollowed and a non-hollowed object, you will see that the price of the hollowed one is significantly reduced.

Choose the right 3D Printing Material

It is obvious that not all the materials cost the same. In general, plastics are less expensive as 3D printing materials than metals. The price of the materials depends on their composition, the cost of production, their mechanical properties and many more factors.

For example our Rigid Polyurethane 70 is very stiff and strong with material properties that outperform ABS plastic and Nylon, and for this reason one is to expect a higher price than those.

So, we advise you to choose the 3D printing material that fits your project after considering the needs of your applications. Are you using 3D printing for prototyping or manufacturing? Do you want to 3D print something just for hobby or for professional use? Take into account your needs, and invest in the proper material according to them.

Each one of our material pages include very detailed information about the description of each material, its properties, uses and technical specifications.

To be familiar with our wide range of 3D printing materials, visit our 3D printing materials catalogue. We invite you to have a look at the list of 3D printing materials and get familiar with the ones that you are interested in using.

Choose the right 3D Printing finish

Like in the case of the 3D printing materials, also each 3D printing finish has a different cost and it addresses a different purpose. Some of our finishes require manual post-processing, and this is a factor that increases its price. Through our online 3D printing service, you have a list of 3D printing finishes that fits every budget.

For the majority of our materials we offer the ‘raw’ version, which is the most economical option you can find. With this option, your 3D part undergoes the smallest amount of post-processing, and that’s why it is the most affordable.

In addition, you can check out our latest blog-post about how to choose the right 3D printing finish for your project. Here you can find detailed guidelines about the finishing options that apply to each material and its benefits for using them.

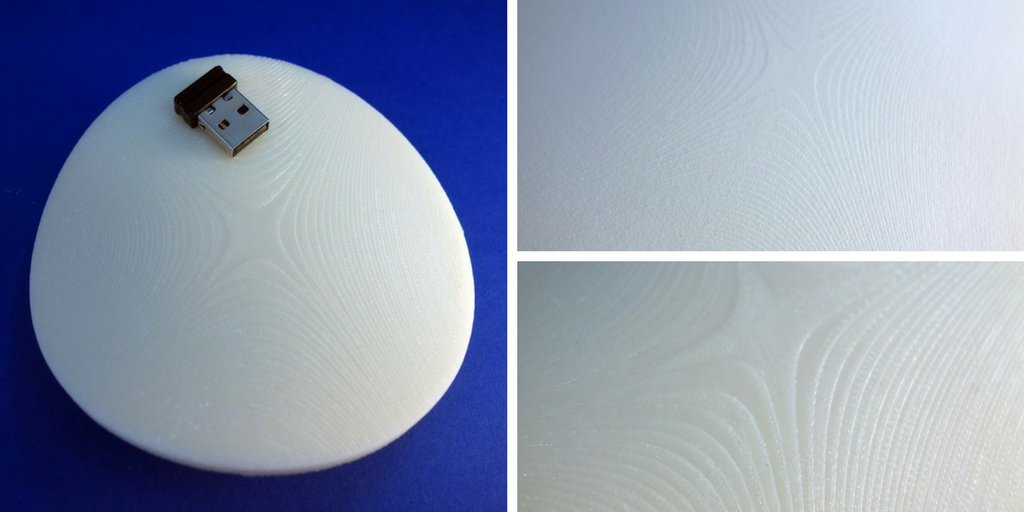

Choose the right layer thickness

The layer thickness is an additional factor that is impacting your 3D printing price. For example, when you are 3D printing with Nylon PA 12 (our white plastic), you can choose between two layer thicknesses: 100 microns or 60 microns. The 60 microns choice is more expensive than the 100 microns, since the resolution is finer and the surface quality of your object will be smoother. So, if you want to save some money in exchange of surface quality of your part, we offer you to use the 100 microns option, as it is slightly more economical.

If you want to get to know more about the Layer Thickness, you can visit our dedicated page.

Size your 3D model properly

The 3D printing price also depends on the amount of material used. That said, we recommend you to size your 3D model to be at the right scale, using our online resizing tool. By adjusting your 3D model to be at the right size, you can significantly succeed in reducing its 3D printing cost. This happens because the 3D Printing Price is also proportional to the volume occupied by your object in the 3D printer’s batch. So, if you scale down your object or adjust some of its aspects, your 3D printing price will be changed automatically.

To sum up, if price reduction is your priority, there are many ways to help you succeed in ordering an affordable 3D print. To do so, you first have to understand how the 3D Printing Pricing works.

To begin with the 3D printing process, you can first upload your 3D file on our online 3D printing service and adjust the printing parameters accordingly. Select the right material, finish, size or shipping method depending on your priorities, in order to get the most value-for-money 3D printed part!

And don’t forget, until February you can answer our annual 3D printing survey and you will get a 10% discount on your next order on our online 3D printing service. Moreover, you have the chance to participate to our drawing lots in order to win a 100$ Amazon gift card. Don’t miss the chance to fill in the “The State of 3D Printing” survey and get the most out of our promotional offer!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook