3D printing metal: The complete Q&A about our bronze material

Posted By Marianna Papageorgiou on Mar 1, 2018 | 0 comments

Recently we introduced you to our new 3D printing metal: bronze. With this special Q&A we will go through some of the most interesting topics about this material and answer to questions we have been receiving from our customers. We hope it’s a useful guide for you to start experimenting with bronze and create unique 3D printed masterpieces with it.

What is the bronze material made of?

The bronze 3D printing material is a metal alloy composed of 90% copper and 10% tin. As you can see from the pictures, it has a reddish-yellow Standard 14K color. Thanks to this, it has a harder surface that doesn’t get oxidized when exposed to air.

In addition, the bronze material is characterized by a much higher resistance to tarnish than brass alloys.

How does the 3D printing with bronze procedure work?

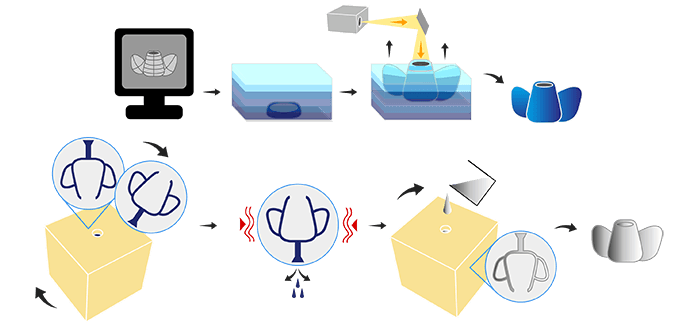

Bronze is printed with the Lost-Wax Metal Casting technique, like Silver and Brass. The procedure starts with first 3D printing the 3D model in wax, which allows for an extremely high level of precision in your designs. During the 3D printing procedure, the 3D printer automatically generates a set of supports for the model to be printed properly. Those supports are removed after the printing process.

Then, the 3D printed model is covered with a stone-like material. The next step consists of heating the wax, so it’s melted and drained through two holes that are left on the stone material. Then, the model is filled with bronze, left to cool down and when it’s ready the cast is removed by hand.

What are the available finishes for bronze 3D printing metal?

You can order your bronze either Raw or Mirror Polished.

The raw option is the most affordable one and it means that your 3D part is sandblasted but unpolished.

The Mirror Polished option means that your 3D part is polished through to a mirror shine in 3 steps through with both a tribofinishing machine and hand polishing. However, keep in mind that after the post-3D printing process some details may be less visible or lost.

What are the size limitations for 3D printing with bronze?

In order to 3D print your 3D model in bronze, it should be up to 88 x 88 x 120 mm.

Are there any design tips for 3D printing with bronze?

When designing for 3D printing with bronze, you should keep in mind the stemmed elements. Stemmed details and ring bands must be at least 1 mm to avoid being deformed. Also, consider that during polishing stages, details and small holes may be lost partially or completely, and interior details cannot be polished. Moreover, the minimum wall thickness of the particular design aspects should be at least 1 mm.

Are there any datasheets for the bronze 3D printing material?

For more details about the technical characteristics of our bronze 3D printing material, you can consult the dedicated datasheet:

- The bronze material datasheet and

- The material safety datasheet

What can I create with this 3D printing metal?

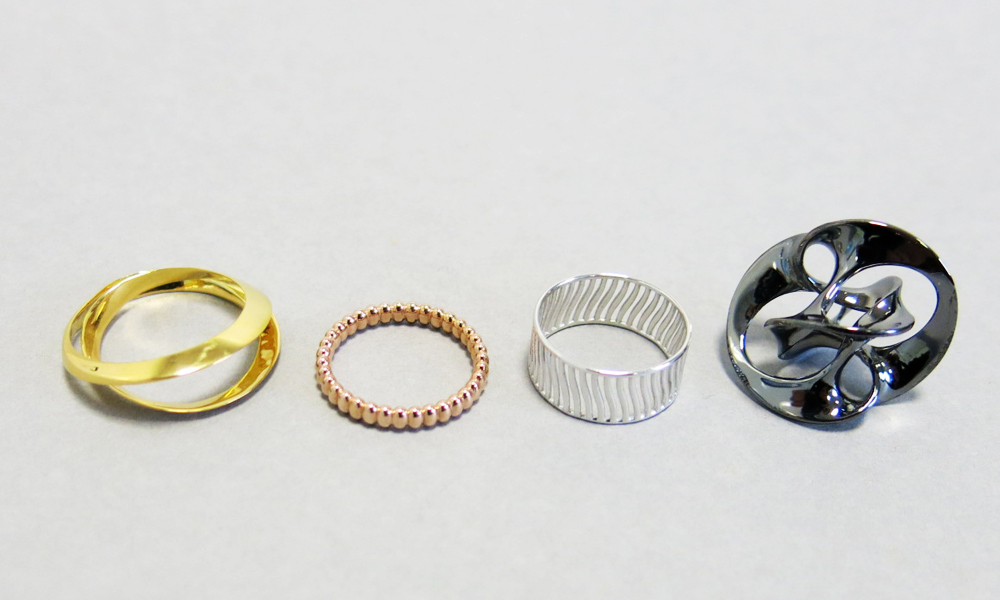

You can use our bronze 3D printing material for various applications in Additive Manufacturing. One of its most common applications is in the jewelry industry, for the creation of precious bracelets, rings, pendants etc. Moreover, you can use it for the creation of any other kind of decorative parts, belt buckles and more. Remember that bronze is a precious metal, yet very affordable. In addition, it is safe for your skin, and will cause no harm even after extensive contact with it.

When will I receive my bronze 3D printed parts?

The estimated shipping time is calculated automatically the moment you upload your 3D model on our platform. The bronze parts with Raw finish are shipped in 7 business days and the Mirror Polished ones are shipped in 9 business days. Keep in mind that delivery is added to the processing time. The shipping speed is determined by the shipping option you choose at checkout.

What other metals can I 3D print using the casting technique?

We offer 3 3D printing materials for the lost-wax casting technique:

All of them use the same 3D printing method and thus they can be used as the perfect fit for the creation of jewelry or decorative parts. More specifically about Brass and Silver:

The Brass 3D printing material

Brass is a 3D printing metal that is often used for creating jewelry. It is composed of 80% copper, 15% zinc and 5% tin, and as we recently introduced to you, it comes in

4 new metal finishes: White Rhodium finish, Black Rhodium finish, Flash Gold plating and Flash Pink Gold plating.

Thanks to these finishes, your 3D part will get a gold, a pink gold, a silver or a black look. Moreover, by plating your 3D part with one of these finishes, you protect it against the oxidation in air, especially in humid conditions.

The Silver 3D printing material

Silver is a 3D metal that is composed of 92.5% pure sterling silver and 7.5% metal alloy. Thanks to its shiny silver surface, it can be a great choice for creating decorative parts or jewelry of great geometric complexity. The available finishing options are Raw and Mirror polished.

Are you ready to 3D print your own parts with bronze or any other 3D printing material? Just upload your 3D file here, we will 3D print it and we will deliver it to you!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook