How to find manufacturers that will fit your needs?

Posted By Lucie Gaget on Mar 7, 2018 | 0 comments

You are developing your company? Or just looking for a new and better manufacturer for your project? You are certainly wondering how to find the right manufacturers. Whatever the kind of business that you are running, you need to find manufacturers and suppliers able to deal with your product ideas. Getting efficient resources for the manufacturing of your products is essential.

In this blogpost, we will give you some tips and some ideas that could clearly help you to find a great manufacturer for your products. We will see what the aspects you have to take into account are.

Why is it so important to find the right manufacturer to develop your business?

You have to find a partner that will clearly fit your needs and will match your business strategy. Finding a new manufacturer is an important step, you need to keep your needs in mind and be patient and persistent in your researches. In the end, having a manufacturer fitting your business plans will have a lot of benefits for your company!

The right manufacturer will help you optimize your supply chain

Whatever the type of business that you run, you need a manufacturer. The role of the manufacturer is to produce your own product idea. If you choose your manufacturer really carefully, it will allow you to optimize your supply chain. It is really the key if you want to offer the best finished products and get high quality devices for your customers.

The goal is obviously to get good quality products, in a quick turnaround time, at a lower price. To really optimize your supply chain, you will have to see what your priorities are and anticipate your needs to get the best results and save money. Finding the right combination for your business will allow you to get an optimized production process

You always want to get the best quality possible for your products, but at the lower cost. This is understandable, but that is why you have to spend a little bit of time looking for a reliable manufacturing partner! Finding the manufacturer matching your project is a real opportunity to improve your business. The more your manufacturer matches your needs and your specificities, the more your supply chain will be optimized.

Indeed, it will allow you to save a lot of time. First you will be able to communicate quite easily with your manufacturer, you will not waste your time, your collaboration will be efficient. If you are confident with the quality of the parts produced by your manufacturer, you will be able to make use of them immediately, you will not have to return the parts. It is the same for your customers, if they are happy with your products, they will not return them. If you avoid all of these problematic situations, you will save time, but also a lot of money!

It will help you satisfy your customers

You obviously want to satisfy your customers and offer them the best products. So you have to get manufacturers that will entirely match your expectations. If you can’t trust your manufacturer, your customer will not trust your company. Your strategy has to be customer oriented, because in the end, your products are for the customers. You have to offer products with a good quality, at a fair price.

If you offer an attractive product, customer acquisition will be easier. Logically, their satisfaction will allow you to get a good reputation. It will be quite easy to keep these customers and to find new ones.

To find your manufacturer you have to ask yourself the right questions: what do you want, what does your business need, and what do your customers need? You have to clarify what you are looking for. Here are the aspects that you have to take in account to select wisely a factory to manufacture your products.

Choosing the right manufacturers regarding your needs

There are a lot of potential factories that could match your criteria. Don’t be afraid to explore all the options, be curious. Here are the main aspects that you have to take into account when choosing your manufacturer.

Do you need to prototype or to produce?

The manufacturer that you will choose has to fit with your project on many levels. You have to find a manufacturer for prototyping but also for your production process. First, it has to fit in terms of manufacturing technique: are you planning to use a traditional manufacturing process such as injection molding, or do you want to try additive manufacturing?

For production, you have to check what the production capacities of the factory are. Are they big enough for you production and for the production that you will need in the upcoming years? Pay attention, because large manufacturers have the capacity, they may have experience but they might be more dedicated to their bigger clients too.

Here is a blogpost about Ikilock, a company creating locks. They talk about their prototyping process and the importance to choose the right prototyping method.

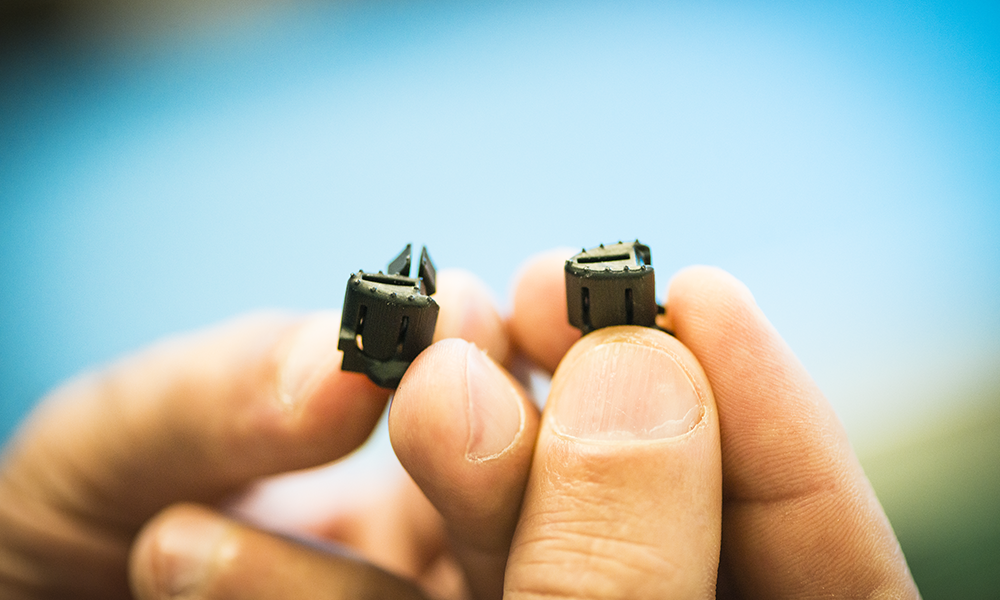

Different 3D printed plastic parts needed for the assembly of the final prototype

What are the materials that you need for your project?

The nature of the parts that you want to manufacture will determine the kind of manufacturing process that you will use. Do you need metal parts? Plastic parts? Resin parts? Do you need whole electronic devices? These main specificities will define your manufacturing process. Your choice is depending on the product that you need to create.

Don’t hesitate to ask for samples of the materials that you want before choosing your manufacturer to see the quality that they are offering. For instance, at Sculpteo, you can get samples of our 3D printing and laser cutting materials to help you make your choice before ordering from us. Discover our samples here.

What about their customer service?

You will need a customer support available if you have any questions, or if you need some advice. Will they be here to guide your through the whole process? Are they answering quickly to emails or phone calls? Will they ship products quickly? Do they offer online resources to give you a hand? You have to deal with serious and reliable manufacturing partners to develop your products. And we are sure that a good communication with your partners will surely help you to improve your manufacturing process.

Factory location: oversea manufacturer or domestic manufacturer?

When you start building your store or any business, you will more easily want to try low-cost solutions for products manufacturing. You may have to choose a manufacturer abroad. Manufacturing in China is often the solution chosen by companies because it is quite cheap. It is actually great to manufacture parts at a lower price, but sometimes, once you get the product, the quality is not here, which can be an issue for customer satisfaction. The price is obviously important, it can’t be the only factor to make your choice.

You can choose overseas manufacturer in China or another country. But some companies want to work with domestic manufacturers. Don’t forget that customers will pay attention to this, they are more likely to be seduced by a company with a domestic manufacturing process. In 2012 a study made by the Boston Consulting Group revealed that 80% of Americans were more likely to pay more for something made in America, as it is supporting local economy. It is an important aspect to take into account when choosing your manufacturer location. It could also be good to know where the factory is sourcing its components from.

For example, the french optic company Octobre71 chose a french manufacturer for their production! Indeed, they were searching for a factory able to manufacture glasses with a robust and customizable material at a fair price, and it was very important for them to produce in France. That is why they chose Sculpteo. It allows to be more efficient in terms of communication, because their is no language barrier. It really improved their development process, as their glasses were quickly delivered.

Our tips to find your manufacturer

See your manufacturer as a reliable partner

You have to find someone reliable that will be able to deliver your products on time, and that will help you to establish your business as a reference. It is essential to feel confident with your manufacturing process if you want to be confident with your own products. Dealing with the right factory could help you to save money and/or improve your business. On the contrary, dealing with the wrong manufacturers could be devastating for your business, and you could lose a lot of money, credibility and energy.

Get informations, ask questions and build a relationship

In order to find a manufacturer that will match your specificities, you have to be curious about the potential suppliers. It could be great to discuss face to face with your manufacturer and why not, visit the factory to see exactly who you are dealing with.

As we saw previously, you are not just looking for a manufacturer, you are looking for a partner that has to help you improve your prototyping or production process. It could be a perfect opportunity to ask all of your questions and get a better overview of the service that you will be paying for. What is the minimum order quantity? What are the production pricing, and the payment terms? Moreover, be ready to negotiate!

What are the other companies that are working with them? Get all the information that you can.

Be patient and compare manufacturers

Taking the time to choose the right manufacturer could really be worth it. Establish a list of potential factories and manufacturers for your products. Don’t hesitate, request for quotations, samples, etc. in order to have a better idea of what they are offering concretely.

These steps can take a lot of time but the quality of your production, the image and credibility of your whole business will depend on this choice. Dealing with the first manufacturer that you find, without being really sure of your choice could be your biggest mistake.

Be curious: try another manufacturing process

Additive manufacturing as an alternative to traditional manufacturing

Let’s talk quickly about additive manufacturing, that could be an option for your production. Additive manufacturing can be used both for prototyping and production! With 3D printing, you have a total control on your product: you make your 3D file on your own thanks to a 3D modeling software, and then, you can get a 3D printed version of it. You can print 10 000 objects, but you can only print one part if you need as there is no minimum order quantity. Did you know that 3D printing could help you to create amazing advanced projects? If it is known to be a great prototyping method, it is now more and more used for production, as we saw in our State of 3D Printing of 2017.

Indeed, in this study, a growing 22% of our respondents were using 3D printing for production. Additive manufacturing is really convenient for production, as you have a lot of freedom. Moreover, 47% of the respondents using 3D printing inside their company saw a greater return on investment than the previous year. This manufacturing process is really helping them to become more competitive on the market.

For production, the 3D printed parts now have really good finishings. There are a lot of 3D printing materials with really different properties and there is necessarily one that will fit your project. When you are just launching your business, 3D printing could really be a solution to develop your ideas at a lower cost. Plus, there is no minimum order requirements. It could really help you to save money!

They use 3D printing inside their business strategy!

If you want to get a great overview of what it is possible to manufacture thanks to the additive manufacturing technology, you can check these blog posts, talking about 3D printing applications:

- Find out the best 3D printed drone projects

- See how additive manufacturing can actually help fashion

- 3D printing can also be a great asset for architecture and construction

- The medical industry is also making the most of the 3D printing industry

- Additive manufacturing can be used to create sport equipments

Moreover, we often share success stories on our blog. For example, check out this one, to understand how a company such as Octobre 71 uses additive manufacturing to produce glasses frames. It could give you a lot of interesting ideas.

If 3D printing is not the better choice for your business, why don’t you try something else? iTabNav is a company selling accessories dedicated to the use of tablets on boats. They chose laser cutting to manufacture their products, as it was more adapted to their project. Discover their success story right here.

No matter your industry, additive manufacturing can always help you to develop your products. You can work in tech, fashion, sell online devices: 3D printing and laser cutting can be used for any kind of business.

We hope that this blogpost, and all of our tips will help you to find your future manufacturer or supplier. Using the perfect material or perfect manufacturing technique, finding a manufacturer available for customers, all of these things could really help you to focus on the essential and improve your business strategy.

At Sculpteo, we can help you with all of these aspects and bring your product to life. You want to try 3D printing to manufacture your products according to your business ideas? You can upload your 3D file on our 3D printing service right now. If you have any question, don’t hesitate to contact our customer service!

If you want to know more about additive manufacturing, you can subscribe to our weekly newsletter in order to get all the latest news and success stories from the 3D printing world.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook