How can 3D printing be an asset for lean manufacturing?

Posted By Lucie Gaget on Mar 20, 2018 | 0 comments

You may have heard about lean manufacturing already. But do you really know what this concept is? We are going to see the definition of this production process and explain to you all its benefits. It could be a great idea to implement this manufacturing process inside your company, as the main goals of this method are to improve the productivity and reduce the costs at the same time. We will tell you more about the lean principles of lean manufacturing. We are also going to explain how additive manufacturing could be a great way to reach this efficient lean production for your business.

What is lean manufacturing?

Where does lean manufacturing come from?

This manufacturing process comes from Japan and has been developed by Toyota. Indeed, lean manufacturing has been popularized by the Toyota production during the crisis, at the end of the Second World War.

The goal was to avoid waste and optimize all the resources. At that time, because of the crisis, it wasn’t possible for the company to stay this efficient without reducing waste. The lack of resources and infrastructures made them create a whole new manufacturing process to stay competitive, by focusing on the essential: the customer’s demand. This process is first known as TPS (Toyota Production System).

https://www.toyota.com/usa/operations/

Improvement of the productivity for lean companies

Toyota created this manufacturing process, and all of this lean philosophy. They are also the first example of the efficiency of this production system. When they began to use this manufacturing process, Toyota was a small company. It is now one of the world’s largest automotive manufacturer. In 2016, Toyota was the fifth largest company in the world by revenue!

Big and successful companies are using lean production: Toyota, Ford, Nike, Intel or FedEx are making the most of this manufacturing method. If we take the example of FedEx, they are doing what is called “C-Check”, it refers to a complete aircraft maintenance. They were doing 14 of them per year before implementing lean manufacturing: it took 32 715 hours to complete the C-Check of an aircraft. They are now able to complete 30 C-Checks per year, as they only need around 21 000 hours to do it, and it is still decreasing.

Other successful companies such as Nike are using this lean production process. Thanks to lean production, Nike increased its production of 20 % and reduced by 6% its CO2 emissions. Some other companies such as Metfrom or L.B Foster increased their on-time delivery to 99 %! These companies are continually improving their results.

https://about.nike.com/pages/transform-manufacturing

The principles of lean manufacturing

Getting started with lean production: Adopt a lean thinking

As we just saw in the blog post, the goal of a lean company is to reduce costs and production time while improving the quality of the products, the delivery time and customer satisfaction. We are going to see the key principles of lean production. The idea of this process is to concentrate on seven axis to improve: you may not pay attention to them, but they penalize your company. Solving these seven problems will allow you to adopt a lean manufacturing process. These issues are called “mudas” (the Japanese word for wastefulness), it is all the things that are making your business waste time, money and energy.

First of all, you have to think about all the steps of your production process and ask: Does this step really add value to the product for the customer? Is this transformation really necessary? Keep in mind that customer satisfaction is your main goal. It will help you to stay focus on what truly matters.

You have to identify and eliminate any type of waste. This idea is that everything, each step of your process has to be necessary and valuable. Otherwise, it is just a waste of resources, both in terms of time, money and productivity.

Studies are showing that the value of the products is added only during 5% of the time of the total manufacturing process. The remaining 95% are a real waste of time and energy. Lean manufacturing is a method that could allow your to reduce these 95% of wasted time and efforts.

Lean manufacturing is a real a way of thinking. It is a constant will of improvement regarding the final product, but also the process. You have to rethink constantly your process to offer the best of your products and services to your customers.

If you want to go further, you have to know that there are also real lean thinking philosophy like the lean Six Sigma, a lean process developed by Motorola.

Seven mudas to avoid in order to improve your process

More concretely, here are all the problems identified by the Toyota Production System, or “mudas”, that need to be solved to avoid any type of waste and reach lean manufacturing:

- Transportation and useless displacements: While moving an object, there is always the risk to lose or damage it. Do you have parts subjected to useless displacements, during or after the production process? Identify them, these risks can certainly be avoided.

- Stock management: You have to get the perfect inventory of your products, from raw materials to finished goods. In each of these states, a product is not representing an income yet for your company, that is why you have to pay attention to what you have and what you precisely need for your production.

- Motion: This muda refers to all the movements made by the equipment or the workers. For example, does the worker have to walk to reach the part? Is it really necessary for the production of the object? Pay attention the overall equipment effectiveness.

- Waiting and lead time: Where is the product while not in transport or being manufactured? Most of the time, the parts are waiting, and once again it is a real waste of time for your production. There are a lot of interruptions between production steps, you have to optimize your supply chain. You have to reduce flow times within your process. What we call “Just-in-time manufacturing” is really one of the main lean manufacturing principles.

- Overproduction: You certainly know it, the customer’s needs are evolving over time. Producing large batches leads to overproduction, which is not really productive for your business. You have to focus on the actual orders of your customers to offer them the best of your company. This way the company can easily adapt to the fluctuations of the market. Producing too many objects will make you waste time, energy, money and even credibility.

- Over-processing: Adding too many processes to the product than what is expected and required by the customer is not efficient. You have to simplify, see what the processes that are really responding to the customers demands are and focus on it.

- Defects: Damaged parts are causing rework. What is the amount of time that you are wasting fixing them? Find the roots of this problem and solve it. Producing qualitative parts will simplify your whole manufacturing process.

All of these mudas have a direct impact on your costs, as they are non value adding operations, that don’t improve neither your product or your process. To produce at lower costs, and to increase your productivity, you have to pay attention to all of those seven points. You can’t neglect one of this mudas if you really want to improve your production process.

Using the right manufacturing process

Now that you understand the lean manufacturing concept, you will have to apply it and begin your elimination of waste. If you want to adopt lean manufacturing and improve your manufacturing process, you will certainly have to rethink your whole process, use lean tools, choose new manufacturers, and try new efficient manufacturing processes.

Indeed, lean manufacturing creates agile companies that are able to rethink their production process continuously. They are focusing on delivering products that the customer wants, when he wants them, with minimum resources. Indeed, customer satisfaction depends on the quality of the products, costs and delivery. Lean manufacturing can be a great asset for your business as it will help you to reach customer satisfaction more easily.

New manufacturing processes, such as 3D printing, could really help you to achieve your goal and adopt a lean production. Let’s see how!

Lean manufacturing and 3D printing

Is 3D printing allowing lean production?

3D printing and lean manufacturing are really compatible. Indeed, using 3D printing could clearly help you to reach a lean manufacturing model, as the additive manufacturing process really has the key principle of lean manufacturing.

If you take a look at it, 3D printing is actually helping to reduce costs, avoid material waste, avoid stocks and create only what the customer ordered. Last but not least: this manufacturing process really improves the quality of the product and shortens lead times.

How 3D printing could concretely help you to solve the seven mudas

Let’s take the seven mudas that we mentioned previously, and see how 3D printing is helping to avoid them efficiently.

- Transportation and useless displacements: 3D printing is allowing to reduce the useless displacements of your parts. Indeed, you don’t have to get through a lot of production steps while using additive manufacturing: you just have to take the parts out of the 3D printers!

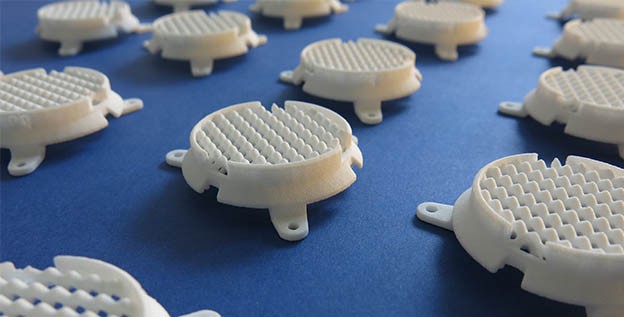

- Stock management: While using 3D printing, you only produce what the customer ordered. It is quite simple: you don’t have stocks!

- Motion: There are no useless motions, the parts are printed in the 3D printers. They are fully manufactured in one place, the workers don’t have to do useless movements to create the objects or assemble the parts.

- Waiting and lead time: 3D printing reduces lead times, there are no different steps to follow. Once the product is manufactured, it is sent.

- Overproduction: You only print what you need while using additive manufacturing, and you only use the amount of material that you need. You don’t produce more than the parts ordered by the customers.

- Over-processing: Once again: You only use what you need and more precisely, what the customer needs, to create the parts. You use one 3D printing material and one finishing if needed, that is all!

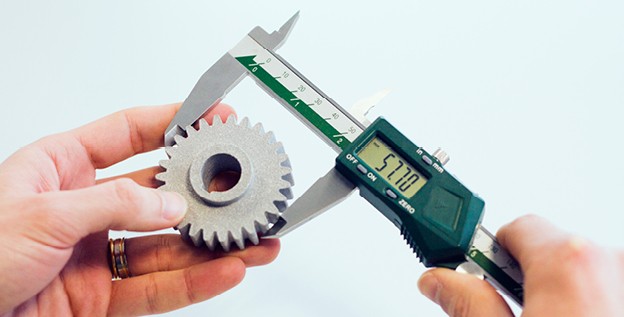

- Defects: If you use a 3D printing service such as Sculpteo to manufacture your parts, there is a quality control. First, while you upload your 3D models on our website, our intelligent tool will analyze the file according to the material that you choose. If the object is not robust enough to be printed or if there is a risk to get damaged parts, you will know it, and you will know where the part needs to be improved. Once the parts are printed, there is a quality control, to be sure that the part is really what you ordered for your company.

Improve your products thanks to additive manufacturing

Lean manufacturing is also a way to improve products constantly, to avoid reworks for example. 3D printing could improve your manufacturing process, but it could also allow you to improve your product itself. Indeed, it is a great method for production but also for prototyping.

You could clearly prototype at a lower cost, by choosing the perfect 3D printing material for your project. Working on 3D modeling software before the printing process also allows you to work on the designs and improve your products. Moreover, as the prototyping process is cheaper, you will be able to make as many iterations as you need.

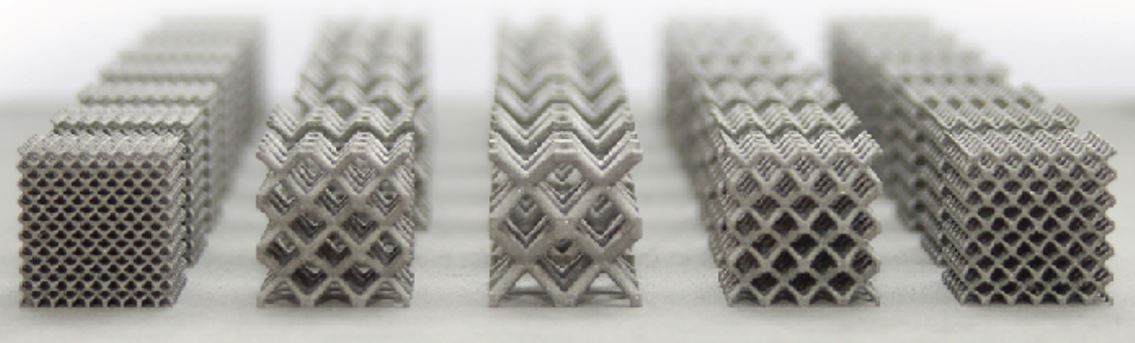

Indeed, it could also allow you to improve your end-use products, as you will access to a wide range of 3D printing materials, with various properties that could perfectly fit your project, from plastic to metal.

Start using 3D printing for your business

If you want to improve your products and your whole production process using additive manufacturing, you need to use professional 3D printers. As it is quite an expensive investment, the best solution could be to produce your 3D printed parts with an online 3D printing service.

What if lean manufacturing and 3D printing were allowing you to improve your productivity of 20%? What if you could increase your on-time deliveries? Additive manufacturing could really allow you to change and improve your production system, and as we saw just above, it could be a way to begin to use lean manufacturing. This production system is always using just-in-time manufacturing, you won’t have to be bothered anymore with stocks, overproduction and over-processes. You will focus on the customers demands and on the essential: their satisfaction.

Moreover, using 3D printing could have a lot of different benefits for your company. If you want to know how this technology is helping businesses, check our our last report, the State of 3D Printing 2017. You will see that for example, this manufacturing process is becoming more mature, and that 47% of the respondents to our survey saw a greater return on investment in 2017 by using 3D printing!

Are you ready to start optimizing your production process and to implement lean manufacturing inside of your company? Upload your 3D files here, and try 3D printing directly, or contact our customer support to get more information. At Sculpteo, we really apply all of these lean principles. We are offering good quality products, and we want to offer the best services to our customers.

Also, if you are interested in 3D printing, don’t forget to subscribe to our weekly newsletter, and get more tips to improve your manufacturing process!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook