Study: 3D printing in aeronautics, a real game-changer

Posted By Lucie Gaget on Jul 24, 2018 | 0 comments

3D printing is offering new perspectives for many different sectors. With our State of 3D Printing 2018, we focused on three sectors making the most of 3D printing, and constantly improving their use of this technology.

We saw it with the industrial goods and consumer goods, but today, we are going to focus on 3D printing in aeronautics, where additive manufacturing is now becoming an important manufacturing technique to improve prototyping and production processes.

Let’s discover aeronautics use 3D printing and learn about all of its benefits for this sector.

3D printing for production

Improving the production process thanks to 3D printing

Additive manufacturing is an amazing prototyping technique. It is a way to make many iterations and develop your product faster, at a lower price. But in some sectors, such as aeronautics, this technology is now becoming a useful production technique.

Thanks to our study, we saw that 64% of the respondents working in this sector are using it for production when 43% of all the users are making the most of this technology for this purpose.

This sector is now using the 3D printing technology for more and more different applications 37% of the respondents are working in a 3D printing first company and 41% are using it in some of their activities. They are not using this technology for only one application, they tend to implement additive manufacturing at different levels

Using metal 3D printing

We can notice a great use of the metal 3D printing technology. Indeed, the most used materials in this sector are metals. 61% of our respondents in aeronautics are using metals and 54% are using plastics. Usually, plastic materials are the most used as they are cheaper and adaptable to any kind of projects.

Some 3D printing materials are more convenient for rapid prototyping. For example, it is cheaper to prototype using plastic materials. But as aeronautics is mainly using the additive manufacturing technology for production, and is usually working on really resistant and technical parts, metal appears to be a great solution for this sector.

Metal 3D printing is more and more developed and aeronautic have different needs and use expensive technologies and materials. Safety and quality are the main priorities in this sector.

Experienced users

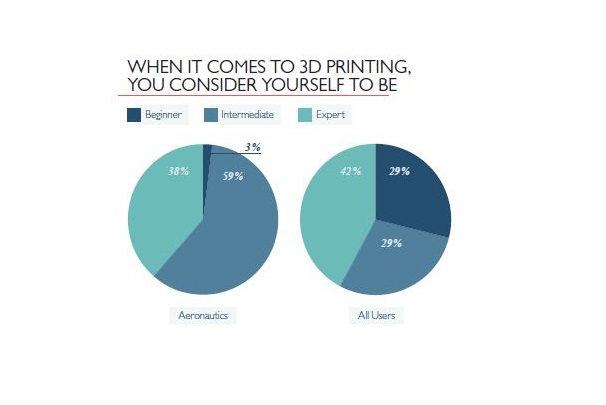

Contrary to other industries, there are almost no beginners using the 3D printing technology in aeronautics. 59% of the respondents working in aeronautics are experts and 38% are intermediates. In this sector, experienced 3D printing users are required to create and work on technical projects.

They need to be experienced to work on production, and to produce quite important parts and design using a 3D software. Don’t forget to check out our selection of the best 3D modeling software for aeronautics. If you need more information to develop your project, contact our sales team.

Advantages of the use of additive manufacturing

Creating technical parts

While using the additive manufacturing technology, you are totally free to make all the designs that you want using efficient 3D modeling software. It is making it possible to build parts with elaborated designs.

Moreover, with the development of XL printers, it becomes interesting for these industries to manufacture bigger parts. 3D printing is becoming a real alternative to traditional manufacturing techniques as it is now allowing these companies to work efficiently thanks to new materials and efficient technologies.

Improving the profitability of a company

We saw just previously that in aeronautics, companies are using additive manufacturing mainly for production. They are actually improving the production process using a profitable manufacturing technique.

71% of the respondents increased their revenues thanks to their use of 3D printing. This result is really promising, and showing that this additive manufacturing technology is now quite useful for various industries, even when it comes to production!

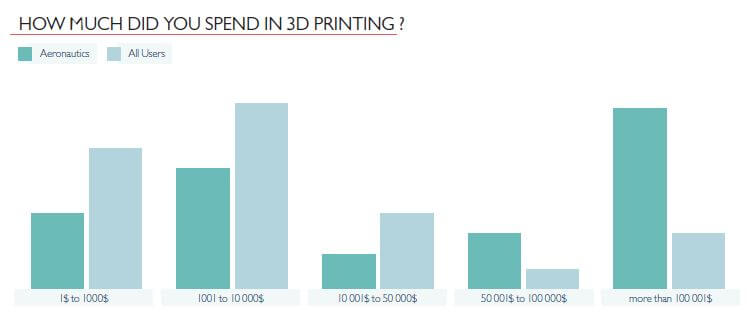

We saw in this study that the budget for 3D printing is really high in this sector, more than in sectors such as consumer goods. It is showing that companies trust this technology and do not hesitate to spend more money year over year in 3D printing.

Indeed, 37% of the respondents spent more than 100 000$ in 3D printing this year. As they are also increasing their revenue, we can say that they are satisfied with it.

Going further: What can aeronautics 3D print?

This technology is really promising for the future of the aeronautics industry. Aerospace, aeronautics, they are all using this amazing technology to build even tougher devices. But what do they print exactly?

Using professional 3D printers is a good way to produce new impressive projects, here are some examples.

Aircraft parts

3D printing is allowing to create aircraft parts. For instance, the company Emirates Airlines used the Selective Laser Sintering technique to build monitoring projects and ventilation grills of an aircraft. Actually, it can be used for various different parts of an aircraft, and it appears to be a good solution to create custom made parts for aircrafts, as 3D printing is allowing mass-customization.

3D printed turbines

Metal 3D printing is allowing to manufacture technical parts such as turbines. Indeed, the project Futuralve wants to manufacture a new technology and more precisely new high-speed turbines, made with metal 3D printers.

These turbines have quite complex geometries, and the only way to manufacture them is to use the 3D printing technology. Renishaw helped to develop a special 3D printing material for this project, a nickel alloy to print these components. The new material has to be lightweight and resist to really high temperature and force.

photo credit: Renishaw

Improving the final products

Pratt & Whitney Engines used nickel and titanium to 3D print some parts of their engines. They developed their product faster than usual, saving months of work, and they also reduced the weight of their arts by 50%. This is the proof that additive manufacturing really allows to rework your product, by finding new designs, more adapted to your projects.

If you are interested in our study, don’t hesitate to download our State of 3D Printing for free. You will learn everything about the professional use of 3D printing. Prototypes and production can both benefit from this amazing building technique in aeronautics.

Are you working in aeronautics and looking for a new production technique? Contact our sales team, they will answer all your questions and you will be able to make the most of our online 3D printing service.

If you want all the information about the different applications of 3D printing in various sectors, subscribe to our weekly newsletter. We will send you our best articles and all the 3D printing news you need to know.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook