The industrial goods sector: A more developed use of metal 3D printing

Posted By Jessica Van Zeijderveld on Jul 10, 2018 | 0 comments

The industrial goods sectors is allowing to produce parts such as machinery parts, tools, components or any goods for use or consumption for many different industries. Industrial goods can improve many different types of production processes, but what can improve the production process of industrial goods themselves? 3D printing is an ideal technology to do so, and many businesses have applied it. The related organizations gave us their insights on developments regarding the use of 3D printing for the industrial goods sector in our State of 3D Printing. In this sixth part on the analysis of the State will give you all the explanations you need on the developments of the past year.

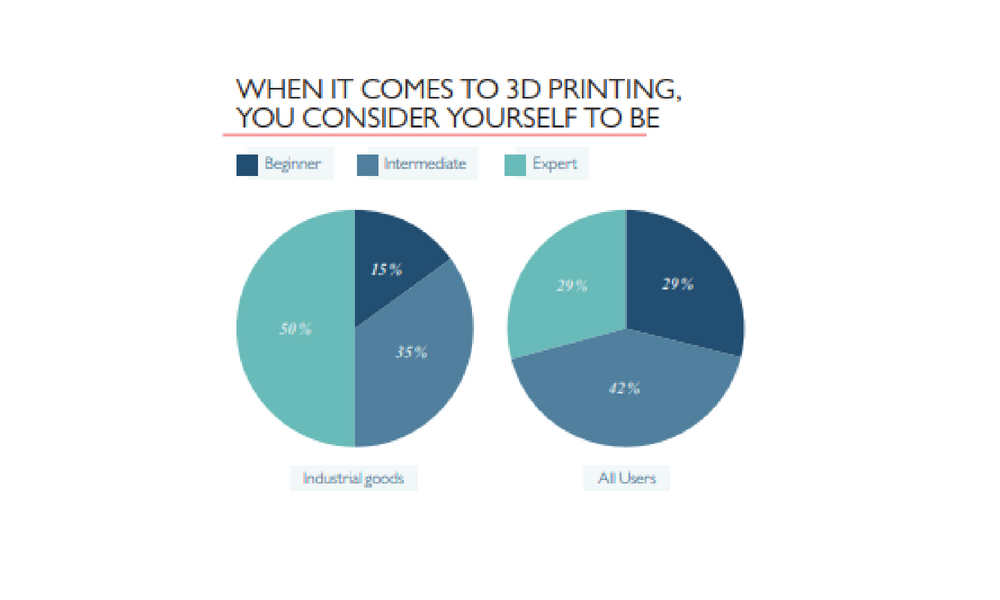

More expertise in this sector

One out of every two respondents who work for the industrial goods sector deem themselves full-on experts on additive manufacturing. For our regular sample, only 29% see themselves as experts. This has to do with the fact that the industrial goods sector find 3D printing beneficial for many different types of applications and intense process methods. This results in the related 3D printing users to match their expertise with the highly advanced and fast-paced processing factors in a shorter period of time.

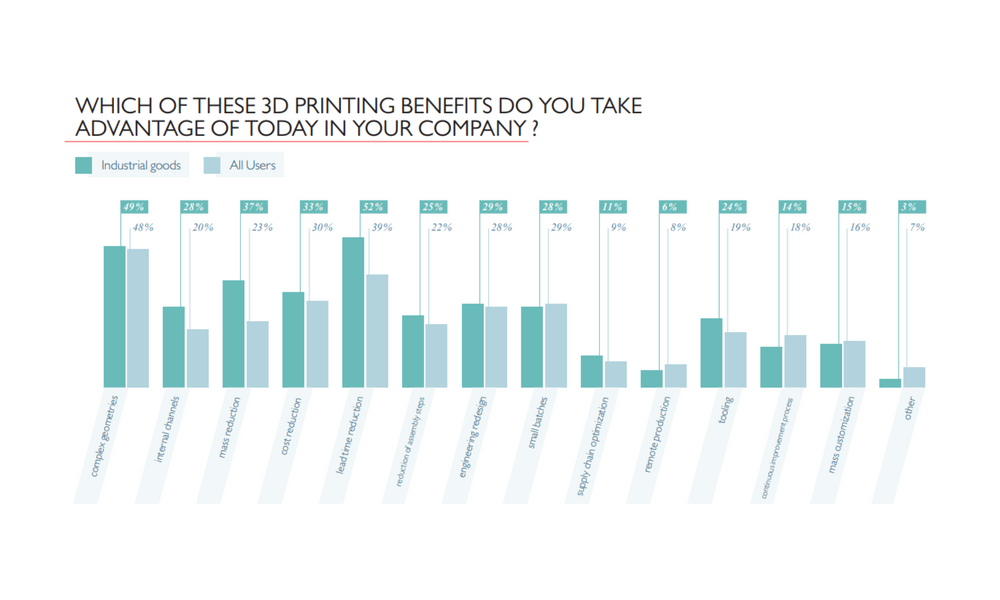

Benefits in lead time reduction and tooling

The industrial goods sector finds many of the same benefits that our regular sample find as well. But two benefits stand out from our regular sample due to the industrial goods sector finding more priority and importance regarding these benefits. These two benefits are lead time reduction and tooling. Lead time reduction was a benefit for 52% of the industrial goods sample while only 39% of our regular sample thought so. As for tooling, 24% of our industrial goods sector found this beneficial while 19% of our regular sample found so.

Lead time reduction allows for companies in the industrial goods sector to produce a product way faster. 3D printing is able to improve processes with quick production or replacement of important production factors such as with bolts and nuts. Tooling is an important factor in getting the most out of lead time reduction. 3D printed tools are low in costs, easy and quick to produce, all the while being adjusted to the required process demands. We can see this with actual application examples in real life as well. For example, companies like Volkswagen have integrated additive manufacturing by 3D printing their tools! These expertly made 3D printed tools, e.g a wheel protection jig normally costs €800 but can now be printed for only €21. Once a tool is not satisfactory enough or is not adjusted to the process at hand, new ones can be 3D printed. Read more about companies that use 3D printed tools here.

Metal material most developed for material usage

Plastics are still the most used materials for the industrial goods sector but closely following up is metal. Metal 3D printing material is chosen by 46% of the industrial goods sample whereas only 36% out of our regular sample chose metal. This can be put into contrast with the fact that plastic was chosen by 56% of the industrial goods sample while 65% of the regular sample chose plastic.

The fact that the industrial goods sector is using more metals and fewer plastics than the regular sample has to do with the beneficial use of metal for industrial goods. Metal materials are more durable, have better resistance to stress and other factors, and are capable of following safety rules that come along with specific industrial goods – making it ideal for the final consumer product that is being supported by this (3D printed) industrial good. A real-life example is that of when 3D printed industrial components were created that allowed for the end product, a submarine, to offer more stability to the vessel. These industrial components were able to hold water and thus stabilize the submarine. Find out more about what can be made with metal 3D printing here.

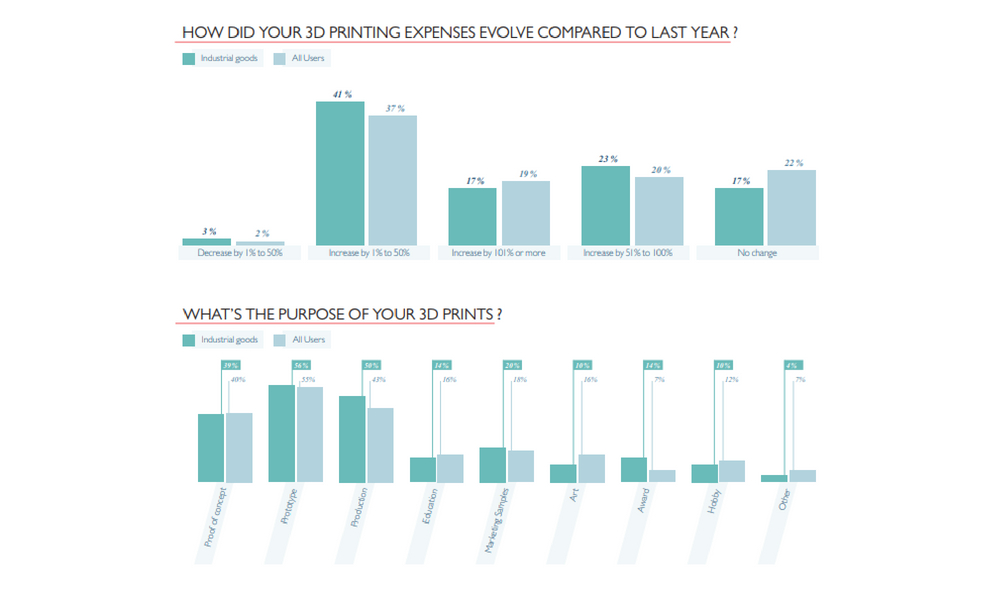

Increased 3D printing expenses due to metal production

We always ask our sample if their organization saw any developments in their expenses regarding additive manufacturing. Not only did the majority of our industrial goods sample (41%) tell us that their expenses increased by 1% to 50%, it was at the same time more than our regular sample said with 37% of our regular sample telling us that their expenses increased by 1% to 50%.

So where do these expenses come from? This has likely to do with their increased use of metal printing compared to the regular sample. Our regular sample is more keen on using 3D printing materials such as plastics, due to their low-cost nature and ideal use for prototyping. However, our industrial goods sample wishes to focus more on production with exactly half of them, 50%, saying so compared to 43% of our regular sample using 3D printing for production. Metal materials are more capable of handling production processes than plastics. However, metal materials are a bit more expensive than plastics. Would you like to know more on how metal 3D printing evolved according to the State of 3D Printing? Click here.

How did other sectors apply 3D printing?

Other sectors like the aeronautics sector and consumer goods sector have used 3D printing in different ways than our regular sample and other sectors have. We have analyzed this with our State of 3D Printing but you will find in-depth explanations on these developments on our blog. In the past, we have discussed developments regarding our power users, profile hiring, material usage and others. In the upcoming weeks, you will find in-depth analyses of the aeronautics sector and consumer goods sector. In order to be the first one to read it, subscribe to our newsletter and find out about the latest happenings in the additive manufacturing industry each week!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook