Rapid Liquid Printing: Creating inflatable structures, between 3D and 4D printing

Posted By Lucie Gaget on Aug 3, 2018 | 0 comments

New additive manufacturing technologies are unveiled quite regularly: new materials, new 3D printers, new 3D printing methods, all of these innovations are allowing new amazing applications. 3D printing is a great asset for the automotive industry, but what if new technologies, new structures, were allowing to go even further and create futuristic cars?

That is precisely what is happening with this collaboration of the Self-Assembly Lab from the Massachusetts Institute of Technology (MIT) and the car manufacturer BMW. A new 3D printing process, the Rapid Liquid Printing technique, allowed them to create new incredible shape-changing structures. More than 3D printing, these inflatable structures are really close to 4D printing.

What are these 3D inflatable structures? How are they developed? Discover this amazing innovation!

Rapid Liquid Printing: What is this new technology?

The creation of Rapid Liquid Printing

In order to create amazing and impressive inflatable structures, the Self-Assembly Lab from the Massachusetts Institute of Technology (MIT) used a technology that they developed by themselves last year. It is called the Rapid Liquid Printing technology. They first used it to manufacture office furniture, but also to create great structures in collaboration with 3D designers such as Christophe Guberan.

They worked on this 3D printing technique to build furniture quite faster, and at a bigger scale than usual 3D printers. The printing speed of this technology is impressive. Let’s see how it is working.

https://selfassemblylab.mit.edu/

What is the 3D printing process of Rapid Liquid Printing?

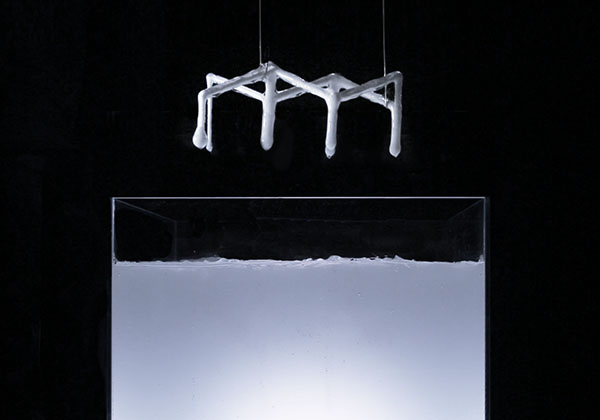

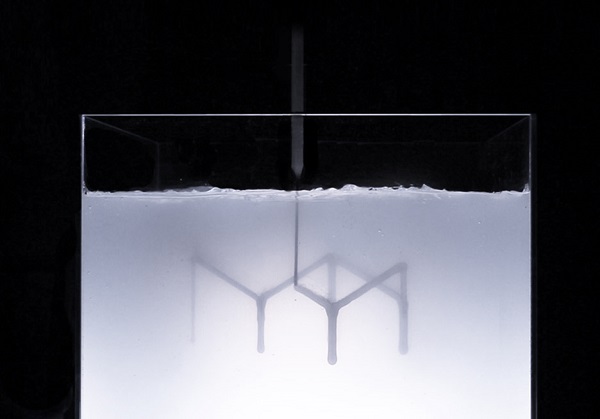

The Rapid Liquid Printing technology uses a robotic system and is able to create objects of any size. It’s not a layer by layer process, drawing the shape of the object freely in space in a liquid gel suspension.

For this process, two different materials are mixed inside the nozzle, and then chemically cured. The gel is here to suspend the extruded material so it doesn’t have to deal with gravity. The printing process only takes a few minutes, and there is no size limitation, meaning that it is possible to print big or small projects.

https://selfassemblylab.mit.edu/

BMW and MIT: A collaboration to create inflatable structures

Additive manufacturing in the automotive industry

We already saw on our blog how additive manufacturing is helping the automotive sector, to create some car parts, or maybe soon, to manufacture a 3D printed car.

This technology is especially convenient to create and replace spare parts, but also to improve some designs and structures, allowing to reduce the weight of some parts. A lot of car parts are 3D printable, for body panels, interiors, etc. It is really helping car manufacturers to create parts for production or for prototyping, it can totally improve the whole product development process.

Indeed, the 3D printing technology can be used on various levels in this industry, not only for automotive parts. For example, Volkswagen Autoeuropa reduced its tooling costs. In 2016, they saved 150 000€. 3D printing tools is also a great way to lower a budget, think about it!

A technology used to build the future

The Rapid Liquid Printing technology developed by the MIT has been used to give life to an amazing automotive project. Indeed, BMW wanted to see how experimental engineering could help them to improve their products. They wanted to use a cutting-edge technology such as additive manufacturing in order to create a futuristic car. This allowed them to manufacture a new pneumatic material, undoable with traditional manufacturing techniques.

What was their goal? To create 3D printed inflatable structures for car interiors. The project is called Liquid Printed Pneumatics. These inflatable structures could allow to create car seats able to change their shape depending on the level of air pressure inside.

They actually succeeded in creating inflatable prototypes! As you can see on the video below, the parts developed by MIT researchers are changing shape and the project is really promising.

Shape changing objects: Meet the 4D printing technology!

The Self-Assembly Lab from the Massachusetts Institute of Technology (MIT) is also working to develop 4D printing. These inflatable structures developed by the MIT researchers can change shape. If Rapid Liquid Printing is a 3D printing technology, we can see similarities making these inflatable prototypes quite close to the 4D printing technology. Indeed, the main specificity of the 4D printing technology is that the printed object transforms itself into another structure over the influence of external energy.

Here, these inflatable structures are totally able to transform themselves. Used for car seats, they will be automatically adapted to the passengers of the car. The shape is autonomous and reacts to its environment.

If you want more information about the 4D printing technology, check out this explicative blog post.

The Rapid Liquid Printing technology is allowing to go further and bring new impressive and interesting projects. Automakers, like BMW, are showing a growing interest for the additive manufacturing technology and they are making it possible to develop new innovative solutions, such as these inflatable structures.

What do you think of this 3D printing project developed by the MIT? Don’t hesitate to share your views with us.

If you want to know more about new 3D printing experiments, subscribe to our weekly newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook