3D printing resin: Q&A about our newest Urethane Methacrylate (UMA 90) material

Posted By Kat Plewa on Aug 7, 2018 | 0 comments

Urethane Methacrylate (UMA 90) is our new arrival to the CLIP resin family. In this blog post, we will show you how you can use UMA and for which needs of your functional parts and prototypes Urethane Methacrylate fits perfectly. First, we will introduce to you the CLIP process for a better understanding of UMA’s properties. Later in the blog, you will learn the characteristics of the new material as well as our tips for your 3D model to be correctly prepared for 3D printing.

Q: How does CLIP 3D printing work?

A: 3D printing your functional parts with CLIP process provide you with a very smooth surface. CLIP means Continuous Liquid Interface Production and represents a photochemical process which uses light and oxygen. The 3D printer, layer by layer, projects light through an oxygen-permeable window into a reservoir of UV curable resin.

Q: What is the UMA material?

A: UMA stands for Urethane Methacrylate (UMA 90). UMA is one of our resin materials used for CLIP 3D printing technology. It comes in two colors: Black and White. Thanks to its properties Urethane Methacrylate is perfect for fixtures, manufacturing jigs and general purpose prototypes.

Q: What are UMA’s properties?

A: Due to Urethane Methacrylate being UV cured during the 3D printing process, the resin has a very sleek finish which makes it stand out compared to other 3D printing materials. At the same time, UMA 90 is strong and stiff which makes it a very good component to produce your prototypes and mechanical parts. To add up to it, our Urethane Methacrylate will fulfill the needs for your parts to be tough and abrasion resistant. All those characteristics combined will resolve in a high standard parts ideal for fixtures, jigs, and prototypes.

Q: How long will the 3D printing process take?

A: To give you the best 3D printing experience your parts will be shipped in just 4 days of the order placement. The delivery time is automatically established during online checkout. Now you can get your 3D printed prototypes without leaving your home in no time! Simply upload your 3D model to our 3D printing service and within just 4 days your order will be shipped. Using Additive Manufacturing has never been so easy!

Q: What are the benefits of UMA 90?

A: As mentioned above UMA stands out thanks to its characteristics, it unites a smooth surface with good mechanical properties. If you would like to incorporate Additive Manufacturing in your prototyping process, Urethane Methacrylate might be just the supreme solution for you.

At Sculpteo we also want to provide you with the best 3D printing service possible, and your 3D printed parts with UMA material will be delivered in just 4 business days. So if you need your parts or prototypes stiff, strong and delivered in no time, our UMA 90 is your answer. All you have to do is to upload your files now and we will take care of the rest.

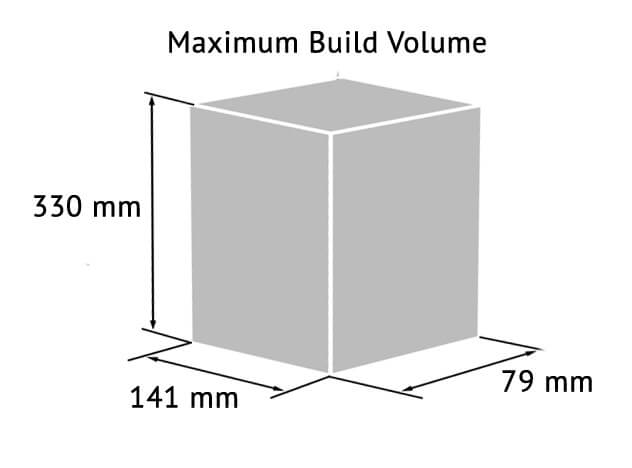

Q: How big can my 3D printed parts be?

A: When designing your 3D models, remember about the size restrictions of the 3D printer. Your parts can be 141 x 79 x 330 mm (5.59 x 3.11 x 12.99 in) big.

As CLIP technology is a layer by layer 3D printing method, it’s also important to keep in mind the layer thickness of your 3D printed part. The minimum layer and wall thickness for Urethane Methacrylate is 100 µm or 0.1 mm. It’s also important for the walls not to be thicker than 10 mm. Otherwise, the material can suffer from heat-related distortion and bubble formation. If you need thick walls for your projects we prepared a blog post about filling them with lattice structures.

The layer thickness has an influence on the level of details on your 3D printed parts. But if your parts are too detailed, the 3D printer will struggle to produce high-quality parts, which we explained in our easy 3 steps guide to optimize the resolution of your 3D models.

Q: What is important to keep in mind when using UMA?

A: UMA 90 has some great mechanical properties, sleek surface and is delivered in just 4 business days. But like with every technology, it’s essential to keep a few things in mind. When preparing your 3D model for 3D printing, supports are needed. They are necessary to 3D print small angles, which are less than 40 degrees. When having the supports added in visible places of your parts or prototype, remember that they have to be removed by hand. We take every precaution for the supports to be removed as neatly as possible, but keep in mind that for the best results the supports have to be in accessible places for our technicians to carefully remove them.

Also, try to use smooth corners instead of sharp 90° angles. You can use fillets, bars or ribs as support during 3D modeling. Find all of our tips on using Urethane Methacrylate for 3D printing in our previous blog post.

Get your parts 3D printed with our Urethane Methacrylate

UMA 90 has proved itself to have great mechanical features, your 3D printed parts will be tough and abrasion resistant. But UMA is a level up also on the looks- smooth surface makes our Urethane Methacrylate material a perfect candidate for your prototypes. And to provide you with the best 3D printing service we will deliver your parts in just 4 days! No more wasting time on your parts to be manufactured with traditional methods. Upload your files and start using Urethane Methacrylate for your additive manufacturing projects today!

And don’t forget to sign up for our newsletter to stay on top of your game with the latest Additive Manufacturing news!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook