3D printing business: What to expect for 2019?

Posted By Lucie Gaget on Dec 24, 2018 | 0 comments

The constant evolution of the 3D printing world offers diverse possibilities, enables new business models, and allows for the creation of amazing designs, impossible to build with traditional manufacturing techniques. If 2018 has already been a great year, what about 2019? What can you expect for your 3D printing business in 2019?

Here are a few insights of what might be the trends of 2019 in the 3D printing industry!

3D printing evolutions for 2019

3D printing and automation

Automation and Artificial Intelligence are big subjects today. The use of AI is already starting to revolutionize our lives on many levels, and 3D printing is not an exception. Indeed, Artificial Intelligence could start to improve your 3D printing experience sooner than expected!

AI could help to optimize your 3D files through 3D modeling software, thanks to automatized actions. It could also help to detect potential defects during a 3D printing process.

3D printing for the medical industry

At Sculpteo, we are seeing a lot of new customers starting to use our online 3D printing service for medical projects. Students, surgeons, and dentists are seeing all the benefits of additive manufacturing for their daily work.

We also saw in our blog posts that 3D printing is saving more and more lives thanks to 3D printed hearts or kidneys. The evolution of bioprinting is revolutionizing the medical industry The lack of donors is a big problem and 3D printing is becoming a serious solution. We could see significant improvements in 2019 regarding bioprinting experiments. We will talk about it on our blog, so don’t forget to subscribe to our newsletter to receive all the news directly!

A growing use of additive manufacturing in the automotive industry

We saw it this year, there is a growing use of 3D printing technology in the automotive industry, to build car parts, elaborate complex and futuristic designs, or to create some great prototypes. We are still waiting for the first fully 3D printed car… Be prepared, this car could hit the road in 2019!

The Italian car manufacturer XEV and the 3D printing company Polymaker started the mass-production of a 3D printed electric car. If you want more information about this incredible project, check out the video below:

3D printing for mass production could really become a new trend thanks to the constant improvement of the 3D printing technologies and the development of powerful and cheaper 3D printers.

Cloud-based software for your 3D modeling process

The future is certainly in the cloud. A lot of 3D modeling software are starting to launch their cloud-based versions, and it could intensify in 2019!

These 3D programs will help you to create your designs and 3D printing projects. With the cloud you clearly help to improve collaboration between all the members of your team, avoid errors and the risks to lose your data.

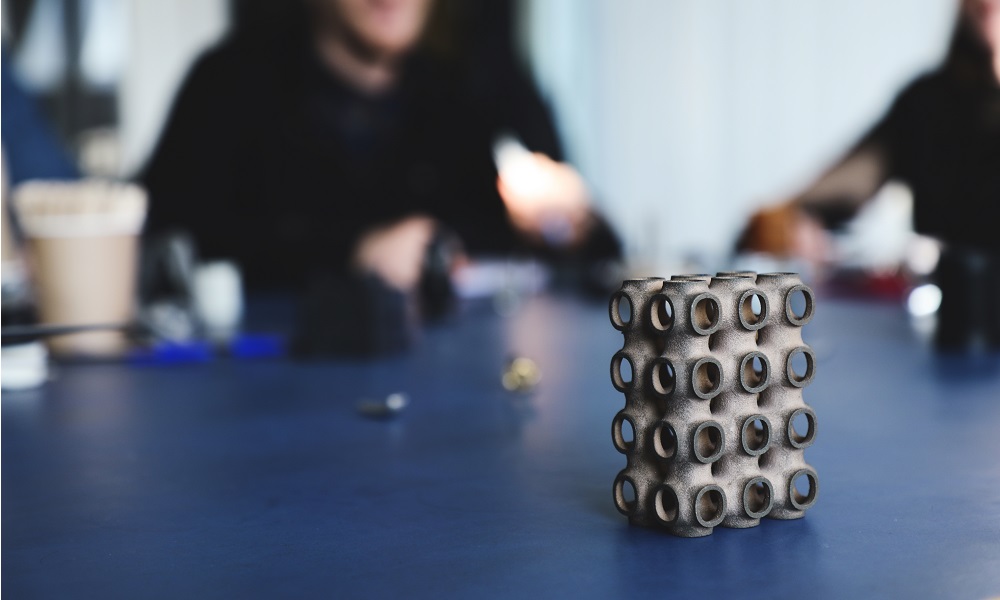

Metal 3D printing

We saw it on our last State of 3D printing 2018, and more recently in our selection of the best 3D printers of 2018: Metal 3D printing is becoming one of the most used and wanted 3D printing technologies.

Indeed, some industries such as aerospace and aeronautics are now making the most of the additive manufacturing technology and metal 3D printing is an interesting process for them.

How your business could start to make the most of 3D printing in 2019

Prototyping

Start to use additive manufacturing for your prototyping process! It is clearly the cheapest and fastest manufacturing technique you could find for your prototyping process. Thanks to 3D printing, you will be able to make all the iterations you need to create the perfect project, you will just have to make the modifications you need on your 3D modeling software, and print your prototype!

You can choose among a wide range of 3D printing materials. If you are looking for the cheapest option, start with the raw version of our Multi Jet Fusion PA12!

Production

Additive manufacturing can also be used for your production process, especially if you need to manufacture low-volume batches! Indeed, 3D printing allows you to create as many objects as you want, but it is particularly cost-effective if you need small volume.

Once again, you will find great 3D printing materials in our catalog. Choose the material with the perfect properties for your project!

Tooling

We know it, 3D printed tools are quite useful. Using additive manufacturing for your tooling process could help you reduce your costs.

For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

Mass customization

Mass customization is one of the main benefits of additive manufacturing. it can be useful for medical application, to create devices adapted to the morphology of a patient, as a prosthesis.

It can also be useful for fashion, to create custom-made glasses for example. The applications of this technology are endless, start to make the most of it with this new year!

Do you want to make the most of 3D printing for your business right now? Upload your 3D files right here and start to use our online 3D printing service!

And last but not least, we will launch our survey for the 5th edition of The State of 3D Printing in the new year, so you can share your insights about your use of the printing technology.

What do you expect for 2019? Tell us in the comment we will be happy to share these insights with you. Don’t forget to subscribe to our newsletter to get all the 3D printing news of 2019!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook