How to use 3D printing to cure deafness?

Posted By Lucie Gaget on May 22, 2019 | 0 comments

We see it more and more often, 3D printing allows new incredible innovations in the medical sector. Additive manufacturing is an outstanding technique to go through new challenges, reach new goals, and when it comes to medical applications, 3D printing can help to cure more and more diseases, bringing adapted treatment and devices to patients.

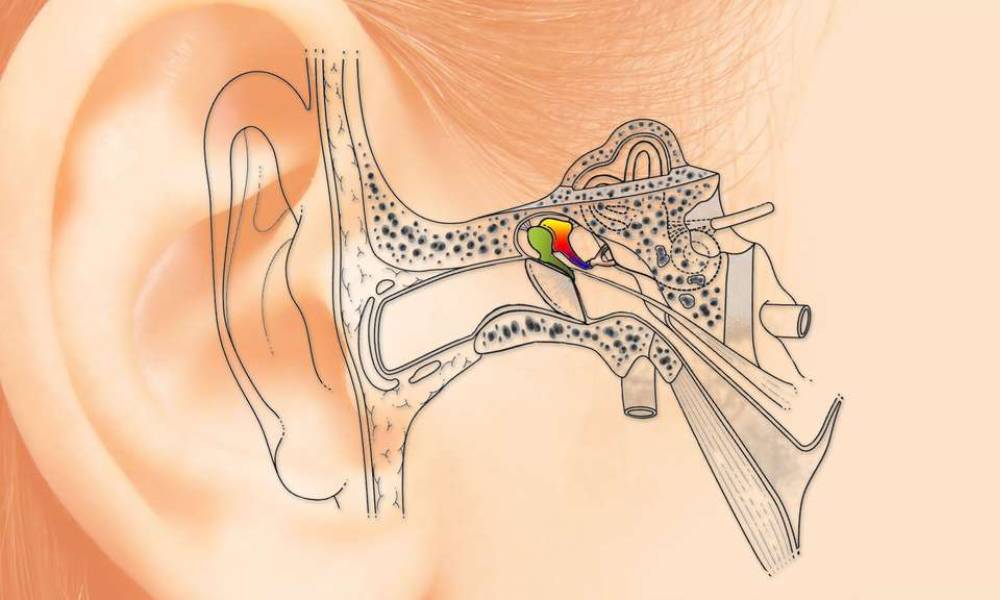

In a world where it is actually possible to use 3D printing for knee replacement, how far can we go? Today, we are going to see how additive manufacturing can be used for a middle ear transplant, in order to help cure deafness. Discover this amazing story right now, and see how it is now possible to use 3D printing to cure deafness.

A middle ear transplant using 3D printing

Researchers from South Africa used 3D printing for an impressive operation, to help cure deafness. For this, they proceeded to do a middle ear transplant. How is it even possible to do a middle ear transplant using 3D technology? That is what the professor Mashudu Tshifularo and his team from the University of Pretoria (UP) Faculty of Health at the Steve Biko Academic hospital are working on.

This operation is actually their first try, but this technique could definitely become a viable solution to deafness. Here is what happened: The patient was 35 years old and lost his hearing because of a car accident, which totally damaged the inside of his ear.

Mashudu Tshifularo, the professor in charge of this operation, has been studying hearing loss for a decade. He recently started working with 3D technologies, to operate on small areas. 3D allows him to scan, and rebuild damaged areas. The professor affirms that 3D is a way to do things they never did before.

The team of researchers explained that the goal in this process was to replace the ossicles that were not functioning properly in the ear of the patient. This technique was actually less risky and heavy than traditional surgical procedures. Titanium has been used for the operation because it is a biocompatible material. This transplant is expected to produce minimal scarring. Reconstructing the inner bones of the ear of the patient is actually a way to restore their hearing.

A growing interest in 3D in the medical sector

We can notice that more and more doctors are using 3D technologies on a daily basis, from 3D scanning to 3D printing, applications seem to be endless. But why is 3D printing interesting for ear transplant? In this case, additive manufacturing is a method to repair only what is damaged, there is no need for a bigger intervention. The damaged parts can be recreated with great accuracy by a 3D printer.

The problem today for doctors is to find sponsors and money to implement 3D printing in hospitals and give access to this technology to all the patients it could help.

The future of additive manufacturing in the medical sector is really promising. It offers accuracy, to print really small parts, but also to create custom-made parts with a biocompatible material. This technology can be perfectly adapted to the needs of any patients.

Are you working in the medical sector and willing to start using this cutting-edge technology? Choose the best 3D modeling software for the medical sector. Visualization, analysis, simulation, 3D printing: improve your daily work thanks to 3D technologies.

Do you want to read more 3D printing news? Let’s subscribe to our newsletter.

If you have any questions about 3D printing or want to start using this 3D technology, don’t hesitate to contact us. We will give you all our tips to make the most of 3D printing in your business.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook