The most promising 3D printed organs projects (2021 Update)

Posted By Kat Plewa on Oct 16, 2019 | 0 comments

We talk a lot about medical applications of 3D printing, but how far are we actually? The year 2020 is getting closer and it seems like the medical world will be shaken up with tests and research on 3D printed human organs. Which projects are the most promising? Let’s find out!

Medical 3D printing: how does it work?

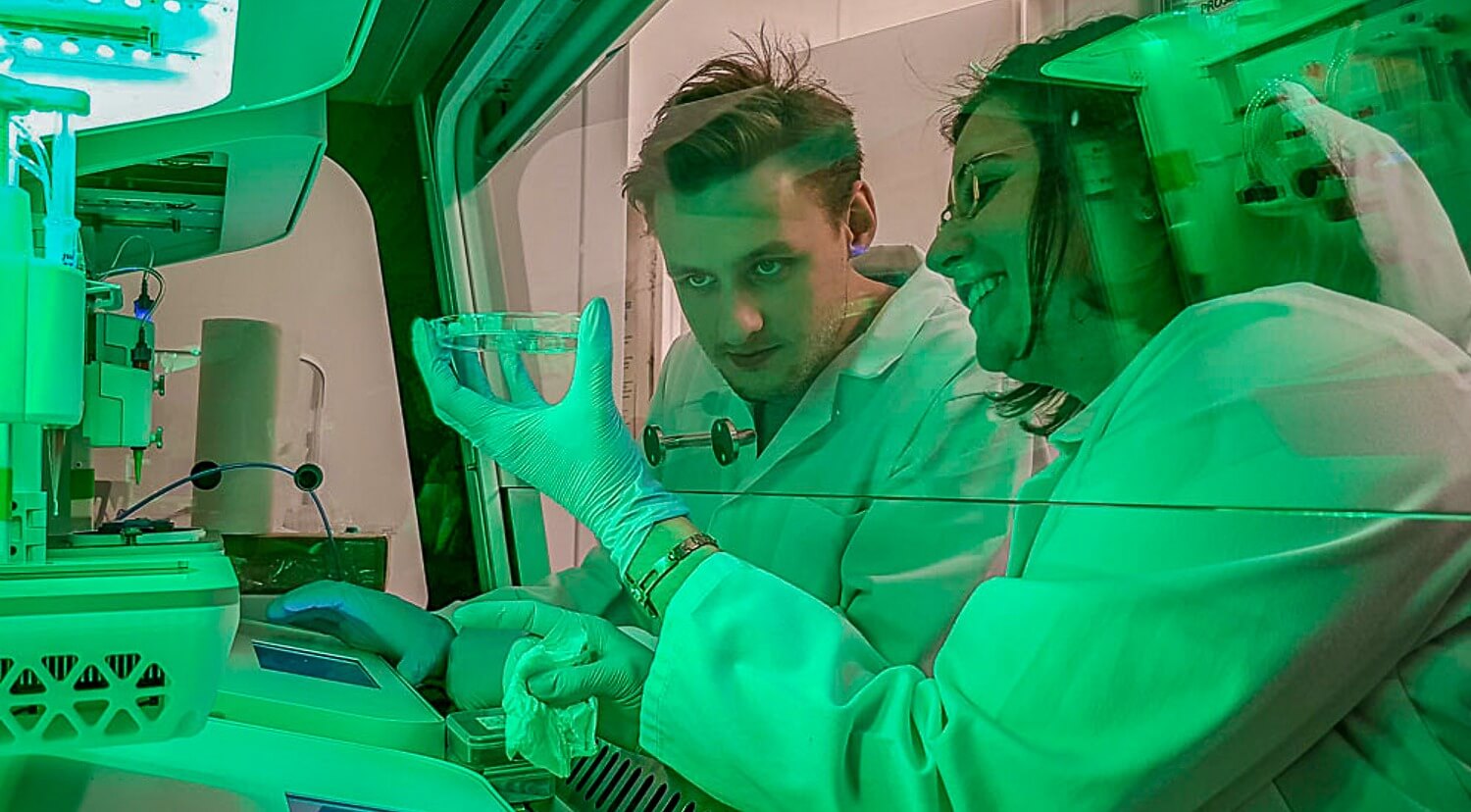

Additive Manufacturing applied in the medical field is called bio 3D printing or simply bioprinting technology. Instead of plastics or metal, it uses natural materials, hence the ‘’bio’’ part in naming.

Biomaterials or engineering tissue is produced layer by layer in order to create a 3-dimensional model. There are different methods of manufacturing the layers, some use nozzles, like most popular 3D printing technology FDM, other use liquid and solidify it with UV light, just the way resin 3D printing works.

What are the benefits of 3D printed organs?

Additive Manufacturing is especially interesting for medical applications. First of all, it gives bioengineers absolutely new materials. Now they can literally build with natural materials, something impossible to achieve with any other technology.

Many impressive researches led to labgrown organs, but thanks to 3D printing, we will be able to actually design a perfect replica of the patient’s organ and then manufacture it!

Using biomaterials, especially from the patient himself, means no more risk of rejecting the 3D printed human organs. Sounds amazing, doesn’t it? Using the patient’s tissue means the DNA of new organ would perfectly match the patients, therefore the rejection risk would be totally eliminated.

Of course, we’re also facing another problem: organ shortage. Bioprinting technology could also fix this issue. The future of medicine and 3D printing techniques is no more waiting for transplant lists and organ donations wouldn’t be needed at all! It sounds like a dream, doesn’t it?

Another benefit of 3D printing is mobility. In the future, every hospital will hopefully own 3D printers, so new organs could be produced locally. But not only that, these 3D printers should be small enough to transport into rural areas or places affected by natural disasters. There, new 3D printed organs and structures, such as bones or skin could be made without wasting precious time on transporting the patients.

Additionally, bio 3D printed structures can be used for drug and cosmetic testing, as they can react like humans. Personalized medicine is another benefit of medical 3D printing, this would mean no more risky treatments such as chemo for cancer patients. The medicine could be tested on 3D printed organs build-out of the patient’s tissue.

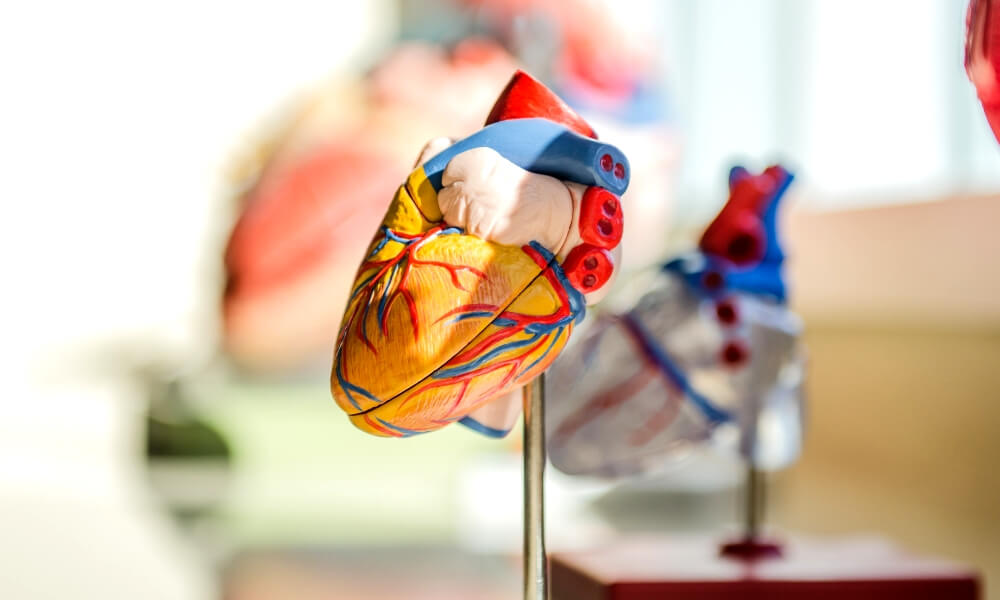

Last but not least, Additive Manufacturing is also widely used for educational purposes and to produce models before the surgery. This allows the future and current doctors to prepare themselves for work with real patients.

Emerging 3D printed organs projects

The biggest challenge of 3D printing organs: vessels

What keeps the organs working are blood vessels and they are the hardest to reproduce. Blood vessels are a complicated network and complex, at the same time need to be flexible to pump the blood and keep their tissue functions. The issue of 3D printing a functional vascular network is called vascularization.

A team from Rice University in Texas might have found the solutions with.. Food dye! The researchers developed a 3D bioprinter using Projection Stereolithography technology. An HD image of a sliced into layers organ is projected onto a soft hydrogel which solidifies thanks to blue light.

The key here is to replicate details of the vascular network. Scientists found the answer in food coloring: yellow no. 5. It is non-toxic, as it’s used in the food industry, and can absorb blue light allowing the hydrogel to solidify at very thin layers. Thanks to this innovative solution the researchers were able to 3D print a small lung!

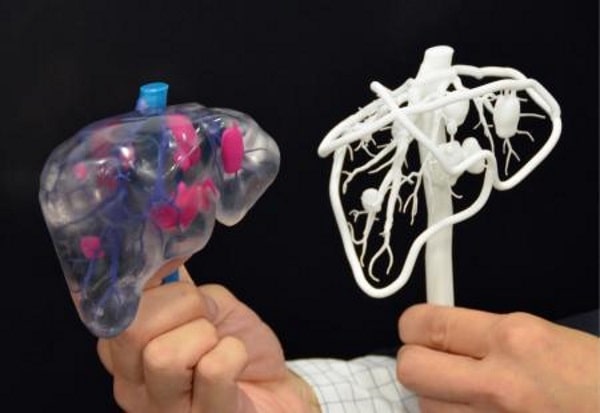

Will we 3D print hearts soon?

Recent developments have been very promising for 3D printing hearts in the near future. One of them includes building support for delicate biomaterial. The scientist from Carnegie Mellon University came up with FRESH technology: Freeform Reversible Embedding of Suspended Hydrogels.

This method allows replicating complex structures that resemble components of a human heart, valves, and small blood vessels. Thanks to the support, the 3D printed human organ is stable during the printing process and can achieve desired properties, which is crucial.

Another project, this time from the Tel Aviv University is not about the support system, but about the 3D printed heart itself. More precisely, the biomaterial used for the 3D printing process. The researchers were actually able to manufacture a small heart with chambers, blood vessels, and human cells!

Professor Tal Dvir points out: ‘People have managed to 3D print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future.”

Bionic pancreas: the future arrived

Earlier this year Foundation of Research and Science Development in Poland published their cutting-edge technology to combine pancreatic islets from animals with bio-inks to support the 3D printed cells in order to produce a 3D printed bionic pancreas. This is especially important for people with diabetes.

Dr. Wszoła, the leading scientist of this project commented ‘’The goal of the project is to create a functional pancreas. One that can be transplanted without major problems.’’

He also added that ‘’No one has yet founded a solid organ with full vascularisation”.

Thanks to a new approach to 3D printing the scientists were able to produce tiny vessels. And although the pancreas wouldn’t be able to fully substitute the organ yet, this revolutionary development proves that we’re just a few steps away from fully functional 3D printed human organs.

Liver: is 3D printing the solution?

http://www.3ders.org/articles/20160127-japanese-medical-insurance-to-cover-cost-of-3d-printed-organ-models.html

Spoiler alert: YES! And it might happen as soon as next year! Unbelievable? It is true though, Organovo, bio 3D printing company from San Diego already tested their functional tissue of 3D printed liver patches in mice which were very promising.

The test proved that the 3D printed human liver tissue was stable and performed well tissue functions until the patient was able to receive liver transplants. It might not be a 3D printed liver yet, but it can extend a patient’s time until an organ is available, which is already a huge success. Human trials are planned for 2020.

Until then, this tissue engineering development is also used for drug testing and research.

Additive Manufacturing for better vision: the 3D printed cornea

3D printed organs can’t surprise us enough. One that might not come to our mind at first is cornea, the first protective layer on our eyes which light comes through. Many people suffer from blindness because of a disease or scratching of the cornea. This is the filed of study for a team of scientists from Newcastle University.

They had two main challenges to overcome: the shape of the cornea and the biomaterial needed to produce one. After studying the eyes of volunteers with a special camera, they developed a curved surface that supports the bio-ink.

Biomaterial used to 3D print a lens was a mixture of stem cells, alginate and collaged. Thanks to bioprinting technology they were able to produce a brand new cornea in less than 10 minutes! However, at the moment this project is at the proof of concept stage, thanks to 3D printing the researchers were already able to produce a 3D printed human organ that can potentially revolutionize the medical industry.

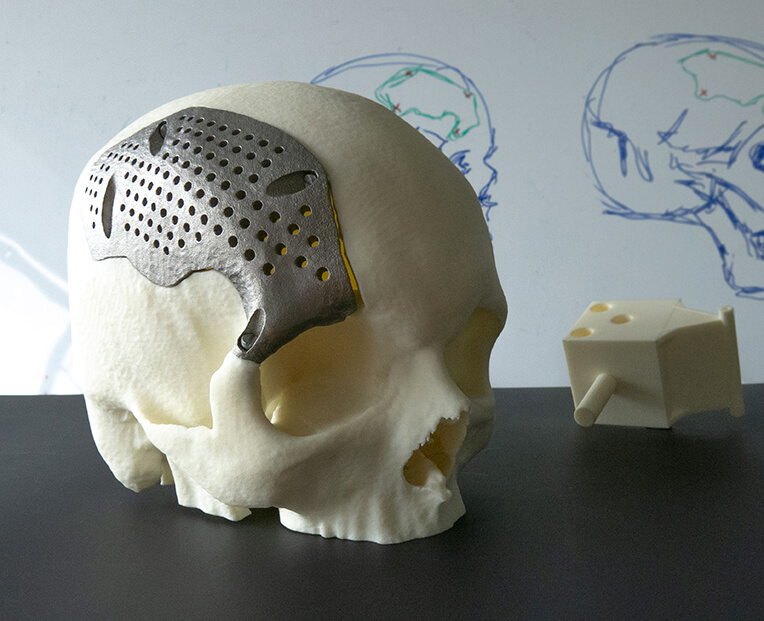

And what about bones?

We talked a lot about soft tissue and hydrogels. But not everything in our body needs to be so flexible. Bones must be strong to support us. A team from the University of Glasgow took on that project using 3D printing.

They developed a new technology called nanokicking. It allowed them to produce 3D samples of mineralized bone structure. First steam cells were taken from human donors, then, thanks to Additive Manufacturing, the human cells were turned into 3D bone grafts! This innovative solution was used for the first time in history.

This technology was already tested. A dog, who was facing a leg amputation, was given new 3D printed bones. The next step is to prepare the 3D printed grafts for implantation, possibly already in 2020.

As you can see the upcoming year of 2020 might be the year of 3D printed human organs revolution. Additive Manufacturing truly has the power to change the face of the medical industry. Starting with educational models, to 3D printed vessels, hearts, livers or bones, doctors and scientists are using a new approach to 3D printing to save millions of lives.

Stay up to date with the latest 3D printing news: subscribe to our weekly Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook