L’Oreal reduces production costs by 33% using MJF technology 3D printers.

Posted By Stephany Vaussanvin on Dec 13, 2021 | 0 comments

Since the COVID-19 pandemic, greater emphasis on creating flexible supply chains and manufacturing processes for businesses to keep a competitive edge has become crucial. So how are some companies doing this and staying competitive? The key is with additive manufacturing, becoming more reactive to ever-changing market trends by decreasing lead times and accelerating time-to-market is possible using this technology. Sculpteo has partnered with businesses at various points in their manufacturing process to help them become adaptable and scalable. Let’s take the example of the famous French brand L’Oreal who used 3D printing to orient their products to be more customer-centered and scale new designs globally below.

Add additive manufacturing to your production process to eliminate any limitations.

At the center of L’Oreal’s decision-making process are two factors; to create better customer experiences and sustainable products. They knew they would need to use innovative technology to surpass their current limitations with their current production process. That is why they turned to HP MJF technology to produce on a large scale additively and completely revise the design of its packaging and cosmetic applications.

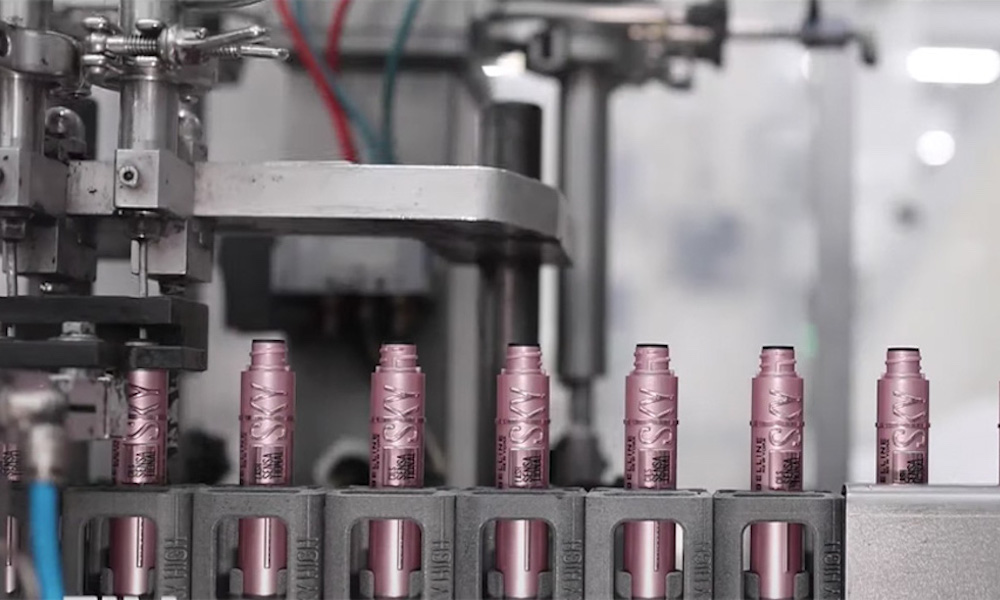

L’Oreal designed several prototypes of their adjustable pucks or buckets (bottle supports integrated into the production line) for their cosmetic application products and printed them with the help of Sculpteo, an online 3D printing service provider, using their HP MJF printers.

Once they determined which design was the most suitable, L’Oreal turned to Sculpteo once again to rapidly produce on a large scale the favored design of their adjustable pucks to be integrated into the production line of their factories in France and Italy.

The innovative, newly designed puck allowed L’Oréal to transport, fill, and label products more agilely while reducing costs by 33% and production time by 66% (source).

Using additive manufacturing to create and test several prototypes and produce a final part all for the enhancement of your production process results in a more efficient and economical way to reduce limitations in your production line. This would not be possible to do with traditional methods like injection molding where it would take several months to test a single design or prototype and then several more months to make a final product, making it impossible to create flexibility in your production line. With 3D printing, you can take several designs and create many iterations to test and then produce a final product within weeks, as L’Oreal has done.

Scale new designs with additive manufacturing

L’Oreal used the flexibility of additive manufacturing, specifically HP MJF technology, to produce on a large scale and create an entirely new design of its packaging and cosmetic applications to respond to the changes in consumer purchasing behaviors since the pandemic. It allows them to achieve their objectives in terms of eco-responsibility by producing efficiently and when there is a demand. L’Oreal plans to use its innovative design globally using the HP digital manufacturing network. As part of this network, Sculpteo will help the french company adapt production in its European market.

“Innovation for the benefit of our customers and eco-responsible products are at the heart of everything we do,” said Anne Debauge, Director of Digital Transformation, Packaging, and Development at L’Oréal. “ We share HP’s vision of pushing beyond our limits with new technologies. 3D printing gives us this entrepreneurial freedom to offer new experiences to customers. Thanks to this collaboration, we have gained agility in our factories and wish to go further by creating new services.” – (Source)

Whether trying to increase your manufacturing capacity or flexibility, reimagine your current products or create new products, Sculpteo’s 3D printing services can help you in your journey. Reduce costs and gain time with 3D printing technology.

Contact us today to learn more about how we can help you adapt and scale your business.

*Featured picture from HP

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook