Bernay Automation relies on Additive Manufacturing to streamline their production process quickly and efficiently

Posted By Stephany Vaussanvin on Jun 23, 2022 | 0 comments

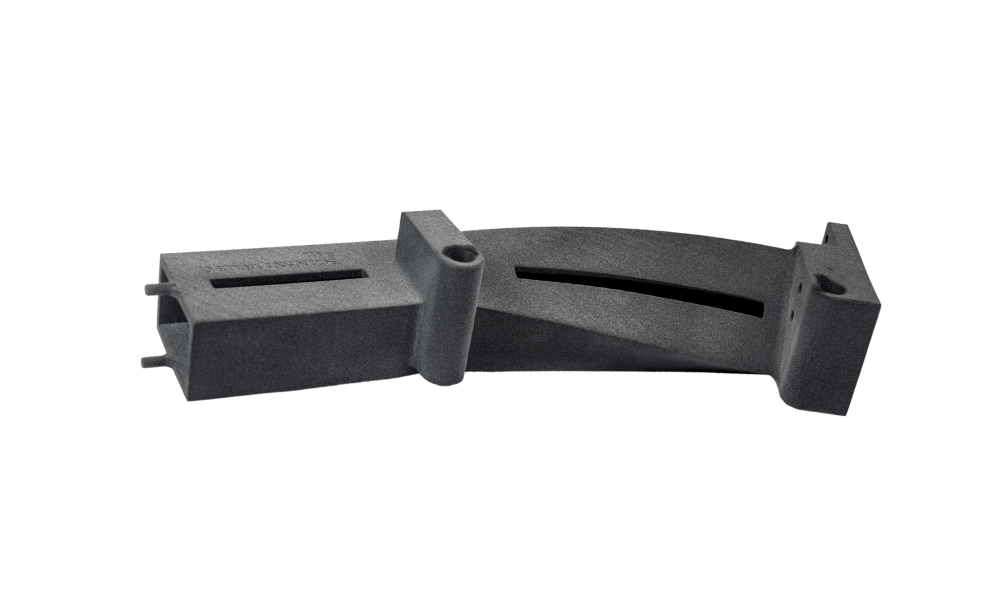

To mass-customize their vibrating bowls in a quick and cost-effective way, Bernay Automation turned to the innovative power of 3D printing and Sculpteo’s reliable online manufacturing services. By adopting additive manufacturing technology into its production process the company was also able to streamline its production process and maintain a competitive edge. Read their success story!

Who they are

Bernay Automation has been manufacturing vibrating bowls and distribution solutions since 1982. They have developed tremendous expertise and offer services in flexible and agile 2D and 3D robotic bin picking solutions.

Bernay Automation manages the distribution of products to arrive in the correct position and at the desired rate on an assembly or packaging line.

Vibrating bowl, plate elevator, conveyor, centrifugal feeder, vibrating platform, or robotic cell integrating vision system, with many solutions available: they can meet their client’s industrial needs.

Their challenges met with 3D printing?

Bernay Automation wanted to create a sustainable product for their clients that was easily customizable, robust and available with on-demand manufacturing. With 3D printing, Bernay Automation found the single solution they needed to meet all their challenges. Read their success story here!

About Sculpteo

Sculpteo, a pioneer and specialist in digital manufacturing, offers an online 3D printing service. Sculpteo provides an online platform to securely upload 3D files and select from over 75 materials and finishing options. Professional engineers and technicians produce parts using industrial 3D printing technologies before sending them to businesses and individuals worldwide. The company is based in Paris and San Francisco.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook