A Revolution for Medical 3D Printing: Pr. Kelly tells us about 3D Printing Bone

Posted By Hannah Bensoussan on Nov 30, 2016 | 0 comments

3D Printing is revolutionizing healthcare in many ways. Today, we share an interview with Professor Daniel Kelly, whose team at the Advanced Materials and Bioengineering Research Centre (AMBER) of Trinity College, Dublin, is taking part in this revolution, by researching how to 3D print cartilage and bone using a “bio-ink”.

Millions of medical procedures require a bone graft every year, and the most common options available at the moment are autograft (grafting some of the patient’s own bone) or allograft (the patient is grafted a part of someone else’s bone). These procedures are complicated and risky, and it’s sometimes difficult to find a donor.

Daniel Kelly’s pioneering research is essential because it paves the way to 3D bioprinting of cartilage and bone, allowing to reduce the need for donors, and to create complex shapes at will.

Sculpteo: Can you explain the subject of your research?

Professor Daniel Kelly: My main work is on understanding how environmental cues regulate the actions of stem cells. Stem cells are the unspecialised cells that can transform into any kind of specialised cell. Using the info I gather on these stem cells’ actions, I look into how to regenerate different tissue types: especially bone, ligaments, tendons, and cartilage.

S: What led you there? What, in your background, allowed you to make 3D printing and biomedicine meet?

Pr. D.K.: I have a double background in Mechanical Engineering and Biomedical Engineering, in which I have a PhD. I teach in The School of Engineering of Trinity College, and at the Trinity Biomedical Institute. So my background and the institution in which my lab works both have a multi-disciplinarity that is pretty much ideal for biomedical 3D printing: mechanical engineering for the 3D printing side, biomedical engineering for the biomedical side.

S: What makes bone particularly difficult to 3D print?

Pr. D.K.: Bone is actually more complex than just a tissue: we consider that bone is an organ, as it is made of various types of tissues. It is made of a stiffer outer shell, a more porous bone part, bone marrow. At the moment, it can’t be 3D printed directly.

S: So what is your team’s approach to 3D printing bone?

Pr. D.K.: What our team did is that we looked at how bone develops, from a simpler tissue that matures into the more complex tissue. And we decided to 3D print the simpler tissue, using bio ink, inside a material that provides the environment for it to evolve into the more complex tissue.

S: Did it work?

Pr. D.K.: Yes!

S: What does it mean? What will it allow doctors to do that they couldn’t do before?

Pr. D.K.: Bioprinting allows to create complex shapes, and it is something that is very much needed. It also allows the decoupling of the mechanical functionality from the biological functionalities: we create the shape that we want, and use the bio-ink that we want.

S: Were you the first lab to manage to do this?

Pr. D.K.: We were. We’re not the only ones working on the subject, but we are the only ones who had the idea of printing the original tissue with developmental precursors instead of the finished bone.

S: Technically, how does it work? Which materials and 3D printer do you use?

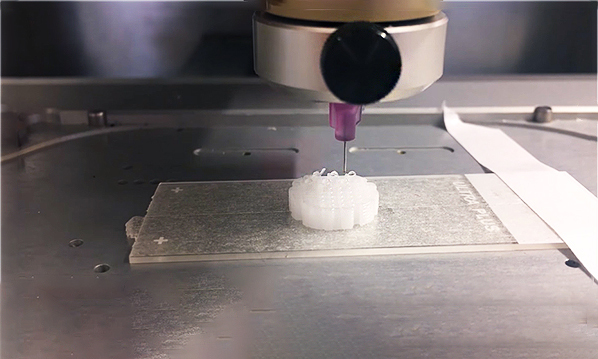

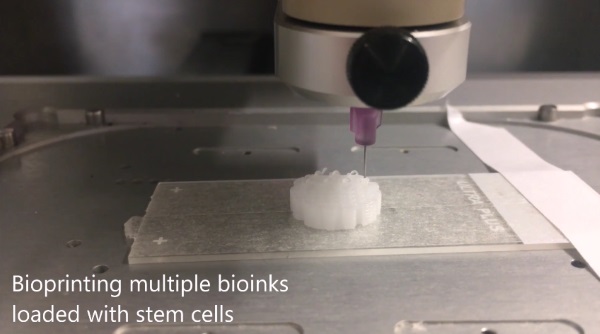

Pr. D.K.: We used a commercial 3D bioprinting system, the 3D Discovery by RegenHU, which has two heads for our two materials (the environment material and the bio-ink). The environment material we used was Polycaprolactone (PCL), that provided mechanical support. In the spaces between the filament, we print a bio-ink that contains stem cells. We make sure that the material degrades and progressively disappears, while the tissue develops into bone. And according to whether we want cartilage (an early stage of development) or bone (a later stage), we engineer the deterioration rate differently, so that it takes more or less time. For the bone, we want the bio-ink to deteriorate faster so that blood vessels form, and for cartilage, the deterioration is longer, so that the ink stays around and prevents blood vessels from coming in.

We can also use the machine with three heads, in case we want bone and cartilage, for specific injuries that affect both (for example, at the knee or the hip). We then 3D print a combination of two different cell types to prevent the cartilage from turning into bone.

S: So should we expect 3D bio printer in every hospital any time soon?

Pr. D.K.: Not quite yet! At least for this application. Our technique is being tested on animals at the moment. It will be 5 to 10 more years before it could be used for humans. But yes, in the future I imagine a bio printer in every hospital, and stem cell banks like we have blood banks.

Our job, for now, is to promote the technology, and go through every stage of the process to make sure it is safe and can be used.

We are very grateful to have been able to talk with Professor Daniel Kelly. We hope you are as excited by the possibilities his research open as we are, as a 3D printing service.

To read more about the applications of 3D printing in the medical field, you can read our dedicated application page and discover other 3D printing materials.

You can also read the following blog articles:

- 3D printing for the medical industry

- 7 things that medical 3D printing can already do

- And the story of one of our customers, who 3D prints medical tools for surgery

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook