Benefits of 3D Printing: Impossible Designs and Internal Channels

Posted By Hannah Bensoussan on Jan 18, 2017 | 0 comments

Last week, we started the 3D printing benefits series with our article on Mass Customization. To continue, we’ll address today another one of the many advantages of 3D printing: the possibility to create “impossible designs”.

In a previous series, we explained the principal uses that can be made of 3D printing (prototyping, production, etc.). In the continuity of this series, we are starting a series about the great Benefits of 3D Printing. Mass customization is the first of these benefits.

This blog post is part of ‘Benefits of 3D Printing’ Series, to elucidate with you all the different ways in which producing with 3D printing has many advantages and can change the industrial landscape.

Find the other episodes here!

Benefits of 3D Printing: Mass Customization

Benefits of 3D Printing: Integrated Assembly

What is called a 3D printed impossible designs?

What we call an impossible design is a design that couldn’t be created using traditional manufacturing techniques. Typically, built-in interlocked objects that require no assembly and can’t be disassembled, internal channels that couldn’t be created without 3D printing, etc.

In this article, I’ll explain those different types of impossible designs and how they solve manufacturing issues.

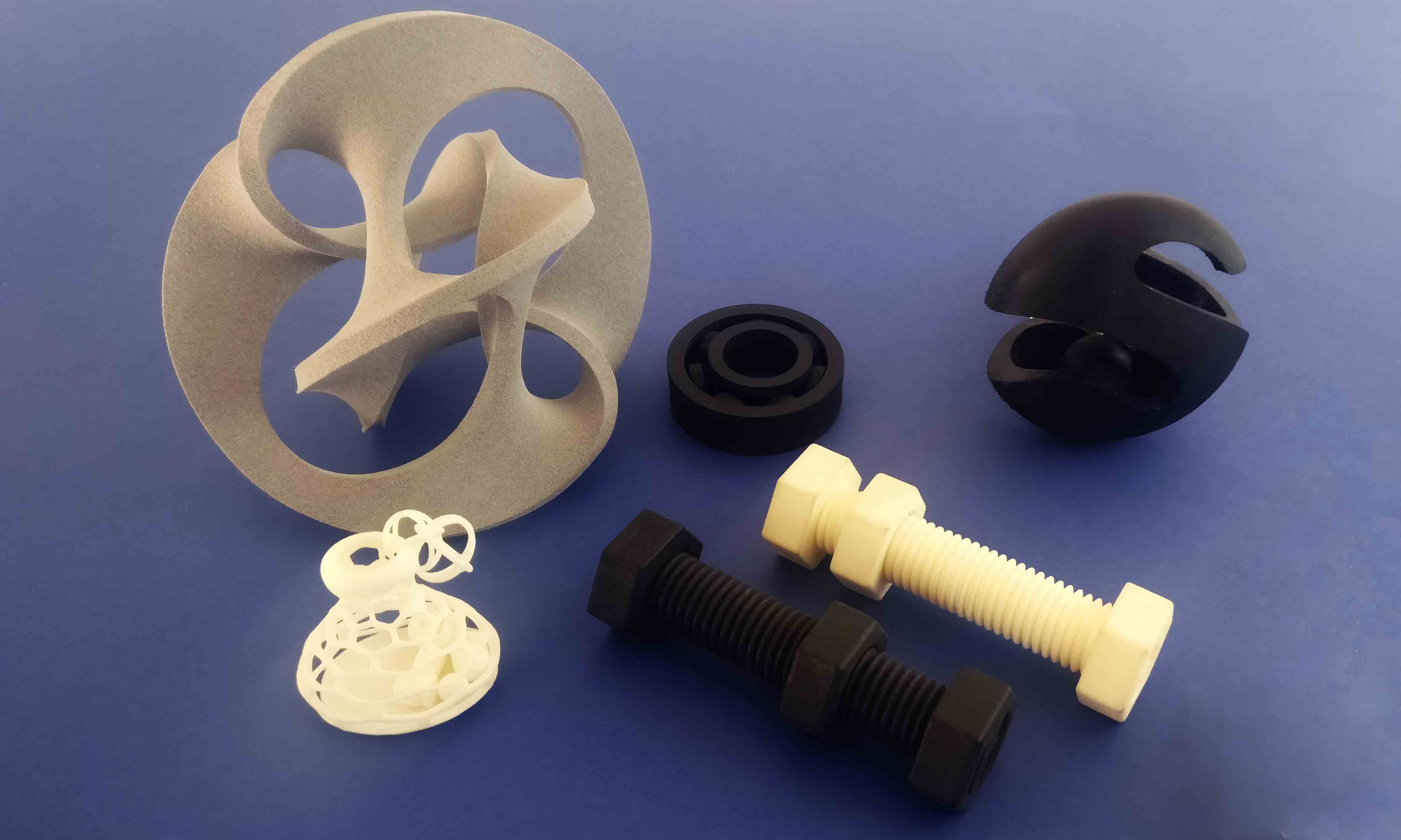

1. 3D Printed built-in interlocked objects with no assembly required

One of the things that are made possible with 3D printing are the combination of multiple parts within a unique object without any assembly step.

As you know, 3D printing is an additive manufacturing process that works layer by layer. Thanks to this, as long as the two interlocking parts are separated by a minimum distance in the design (to prevent them from sticking together), they can be created in just one 3D print.

Hinges, gear bearings and ball joints can be manufactured within the same machine and material to reduce cost and manufacturing time. One can imagine that metal 3D printing can be a valuable step in the manufacturing process for larger objects, mixing traditional methods (machining, molding) to additive manufacturing methods to achieve complex parts.

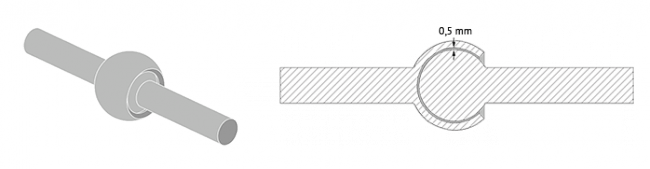

2. Internal channels and no-access features

It is also possible to create cavities and internal features that wouldn’t be possible or would be very complicated to create with traditional manufacturing techniques, as they are limited by the access zone of the various tools that are used.

Internal and cooling channels are often the reason why industrials are choosing additive manufacturing techniques, especially metal 3D printing techniques like SLM or DMLS to create their parts. That allows them to solve structural and thermal issues by designing a model that takes into account stress and can reduce it in an innovative way.

A good example of this is the team of scientists of the von Karman Institute in Belgium, who created a 3D printed metal vane for a turbine. The design of this turbine part included its cooling cavities in order to 3D print them directly. This allowed them to innovate and create a pulsed cooling technique, which reduces the intensity of the shock waves endured by the turbine!

On top of cooling options, internal channels can help reduce a component’s weight. This is an important feature, that is starting to be explored and will be explored more and more, especially in fields where weight is key, like in the construction industry. A good example is Neri Oxman’s alveolar cement design.

As well as XtreeE’s new way to 3D print buildings. You can read a complete interview of XtreeE CEO here.

3. Complex geometries: the example of NightHawk headphones

Some designs allowed by 3D printing aren’t per say impossible with traditional manufacturing, but would be very complex to create, or very expensive. Therefore, 3D printing does make them possible for businesses to afford. A good example of this is the The NightHawk headphones by our client AudioQuest, that we have talked about many times already.

These headphones, produced in series at Sculpteo, integrate a 3D printed part, which has an intricate diamond cubic latticework. These unique parts increase the acoustic properties of the headphones, and exist solely thanks to 3D printing!

When 3D printing solves manufacturing issues

With all these new design possibilities, 3D printing is solving manufacturing issues, and creating new opportunities. In particular, it allows to reduce tooling costs and lead time (thanks to the integrated assembly options), it gives the opportunity for engineers to innovate technically (for example with the cooling channels).

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook