Benefits of 3D printing :The additive manufacturing a revolution for Integrated assembly

Posted By Capucine Lonjon on Feb 8, 2017 | 0 comments

Since 19th Century Industrial Revolution, producing goods required heavy industry, machine tools, production line and economies of scale. In traditional manufacturing, infrastructures and time are mostly dedicated to assembly. The whole Ford system is based on an ‘assembly line’ and is seeking for ways to optimize assembly time.

3D printing is revolutionizing in that it is now possible to minimize assemblies and welding steps. In this way, 3D printing can be time and cost saving.

This blog post is part of ‘Benefits of 3D Printing’ Series, to elucidate with you all the different ways in which producing with 3D printing has many advantages and can change the industrial landscape.

Find the other episodes here!

Benefits of 3D Printing: Impossible Designs and Internal Channels

Benefits of 3D Printing: Mass Customization

Integrated Assembly

What is integrated assembly?

Basically, an integrated assembly is designed to reduce the number of steps required to assemble a product. The designer/engineer directly thinks of a part with several components that will be directly printed all in once, needless of assembly.

Reducing the number of assemblies results in significant time savings, decreasing production time, and decreasing time spent searching for manufacturing methods. Therefore, integrated assemblies can really make you save money.

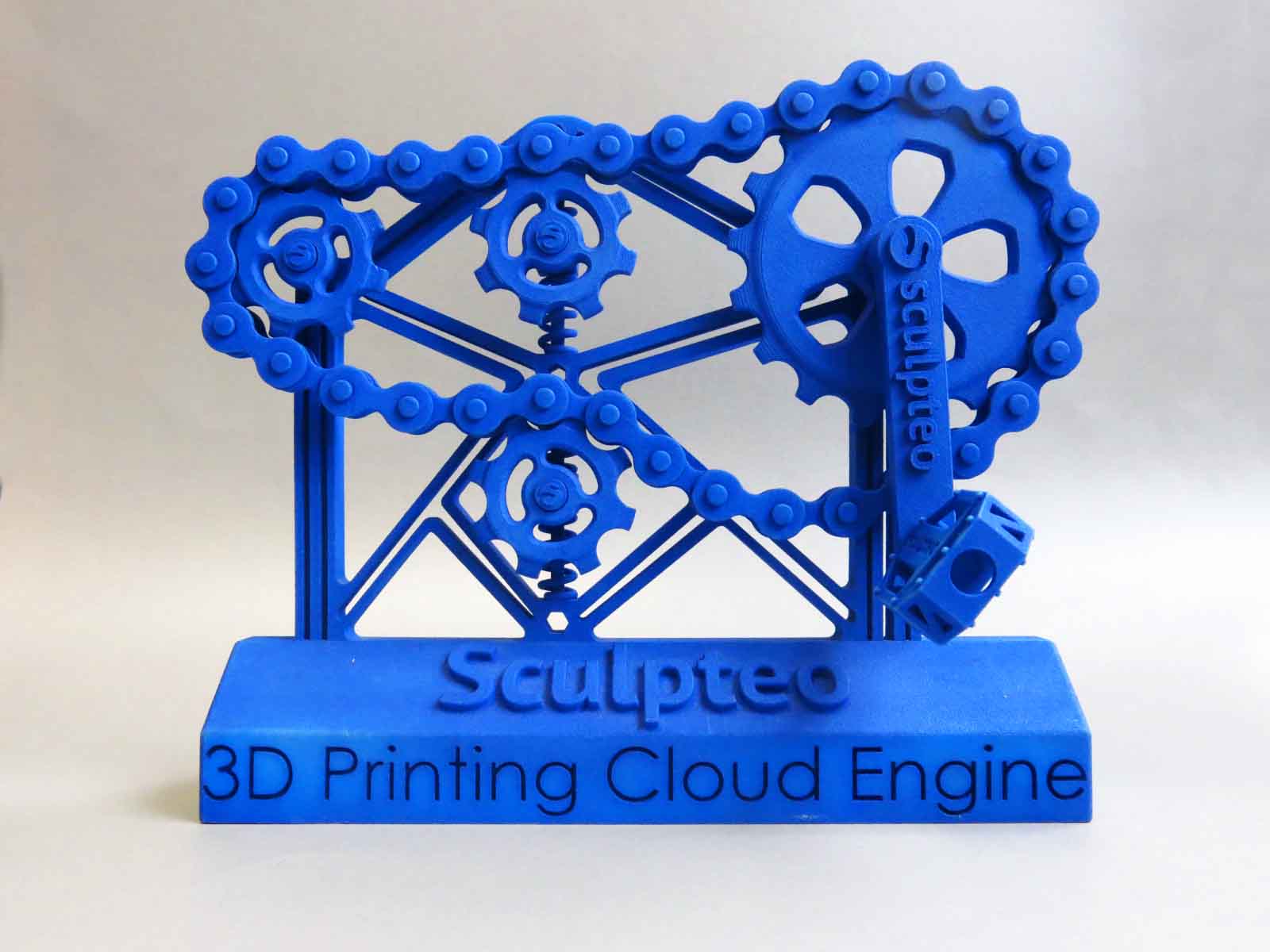

Among the most well-known examples of 3D-printed integrated assemblies, you should have seen:

- chains and interlocking parts

- gearboxes and other

- wrench

Changing the way we produce by changing the way we think production

If integrated assembly saves time on the production line, it can consume more thinking time during the design process.

Creating an integrated assembly is not a beginner exercise and may cost you a few headaches! But the challenge is worth it. It is possible to create integrated assemblies in many materials and many technologies. Materials requesting supports like CLIP resins are a little bit tricky than powder-based materials (such as Alumide or Plastic) because you will need to remove supports before having a fully functional mechanism.

At Sculpteo, we have tested and printed many integrated mechanisms. The most successful were:

- rotating mechanism

- sliding mechanism

- hinges

- crankshafts

- threadings with integrated bolts.

There are some design tips to have in mind.

- choose your 3D printing material first and then read design guidelines carefully. Integrated assembly depends a lot on the mechanical properties of the material

- leave enough space to remove the powder or the supports otherwise your mechanism will feel like seized.

- take the time to rethink the part to its function and get rid of traditional conception. The beauty of integrated assembly is to forget about screws and nails…

- don’t forget about physics: a heavy part won’t slide correctly, a thin part can have less strength etc…

For each material, we have written design guidelines that can help you for starting to work on your design. We have also created many tutorials for the most famous CAD software.

Taking most of the 3D printing assembly

As the whole part is rethought for 3D printing, we can go even further than ‘just’ integrating assembly. It is possible to optimize the part in regards of the strengths that are applied to the part. In our new AMT suite, the ‘Automatic Lattice Generator’ goes in this way.

It is possible to evaluate the environmental impact of your assembly process choice. For example, Solidworks enables this evaluation through its ‘Sustainability’ Program.

How do businesses already use assembly with 3D printing?

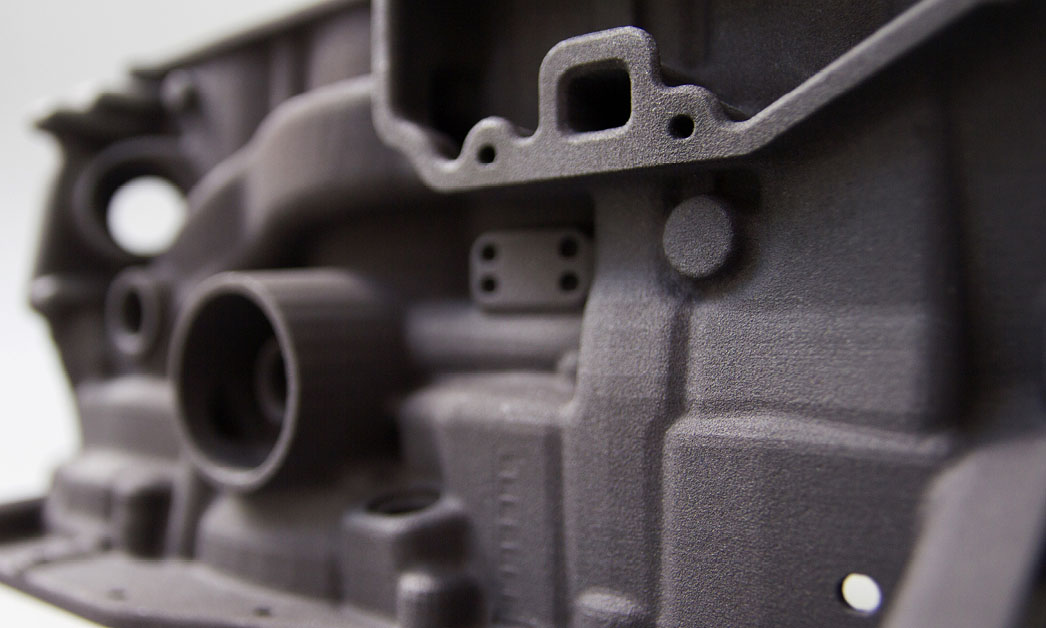

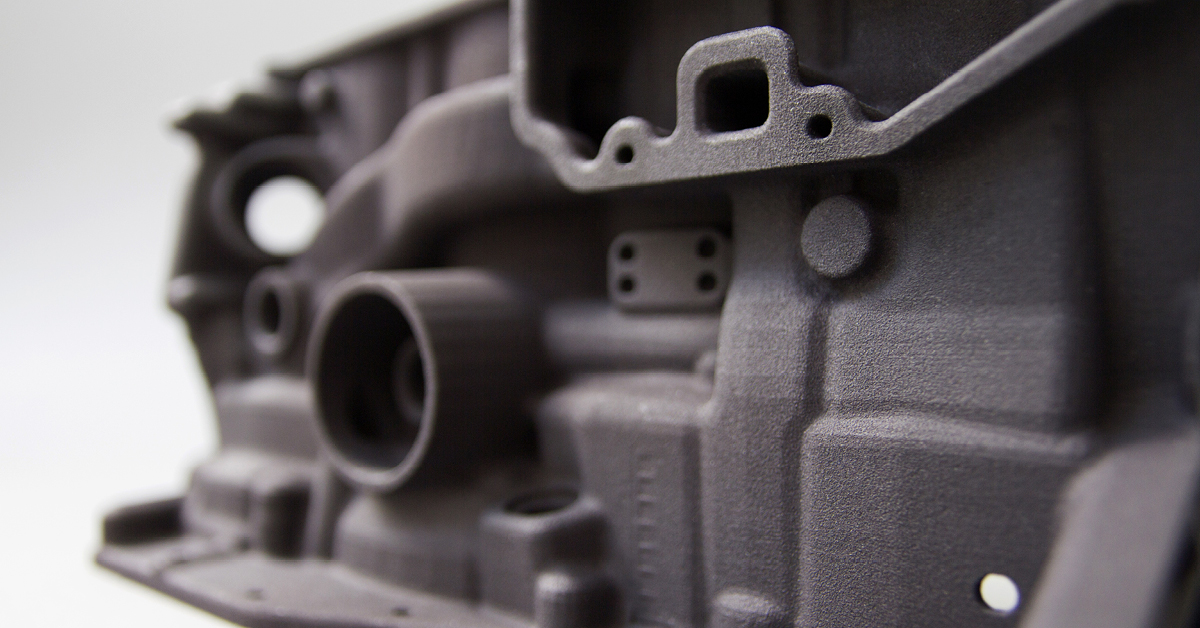

Integrated assembly is revolutionary with the growth of metal 3D printing. Big industries like aeronautics and automotive are changing they way of conceiving.

Integrated Assembly for reducing costs

ULA could reduce a complex assembly system from 140 to 16 parts thanks to 3D printing (photo) for Atlas V. They could reduce 57% of their costs. At an annual scale, they even evaluated annual savings to 1million$.

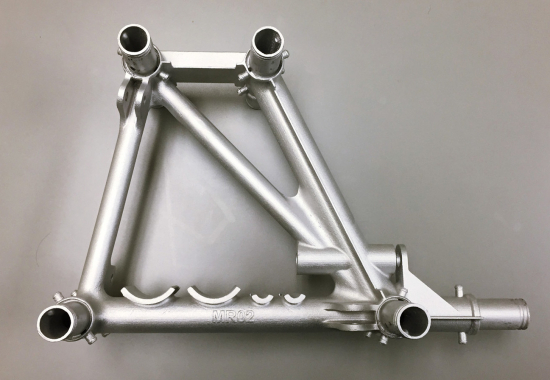

3D printed connections

Instead of welding, you can use 3D printed parts to connect other parts.

For example, for Sculpteo Bike, our two designers Piotr Widelka and Alexandre d’Orsetti designed 3D printed connections for the frame, in painted polyamide. After the whole designing and iteration process, they could assemble the bike in only 40 minutes!

Divergent 3D offers cars that have the particularity to contain 3D printed joints.

Tooling

If sometimes it’s possible to 3D print integrated assembly, 3D printing can ease assembly in another way. Some big companies as OPEL start conceiving tooling with 3D printing. In fact, some toolings are very costly and time-consuming. They require a mix of resins and metal. Thanks to 3D printing, it is possible to conceive them and reduce the price up to 90%.

In this video, Audi explains the efficiency to produce tooling with 3D printing.

To go further

To go further on 3D printing applications, you can download our ebook ‘18 real life cases where 3D printing makes the difference’ and see our dedicated pages.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook