Benefits of 3D Printing & additive manufaturing: Small Batch Production

Posted By Eole Recrosio on Feb 22, 2017 | 0 comments

In this week’s 3D printing benefits series, let’s talk about the small batch production benefits. Not only reserved for traditional manufacturing techniques, it is now possible to integrate additive manufacturing into the production of parts. Small batches are often more interesting to manufacture with 3D printing than with traditional methods (e.g. injection molding).

This blog post is part of ‘Benefits of 3D Printing’ Series, to elucidate with you all the different ways in which producing with 3D printing has many advantages and can change the industrial landscape.

Find the other episodes here!

Benefits of 3D Printing: Impossible Designs and Internal Channels

Benefits of 3D Printing: Mass Customization

Benefits of 3D Printing: Integrated Assembly

Small Batch Production

What Are the Advantages Of Small Batch Production?

Producing in large series is not accessible to every business. It presents a large investment, and a large amount of risks. Producing in small batches allows to test a product on a reduced amount of clients before adapting the next batch. It also allows to reduce stocks, and the associated costs.

Who can benefit from it?

This production method is very advantageous for seasonal or limited quantity products. In sectors where the demand is periodical or not very high, small batch production provides a sustainable manufacturing system.

Additive Manufacturing Makes Small Batch Production Easy

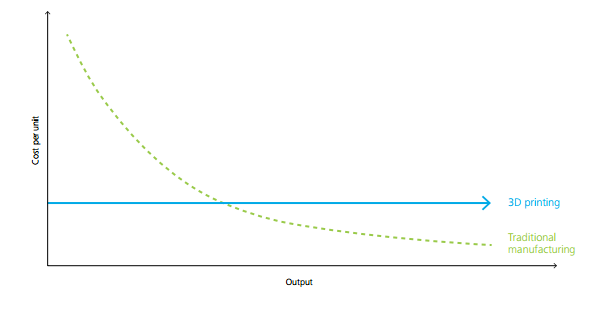

With 3D printing, the cost of one part is usually higher than it would be if it was mass produced using injection, but this higher cost is worth it for small batches. Indeed, for small batches, because you don’t have to invest in molds, tools, metrology, 3D printing ends up being cheaper: the unit has the same price whether you order it 20 or 10 000 times. This gives you the freedom to produce your series in small batches, that can be updated along the way.

The cost per unit of a 3D printed product is the same whereas the cost for a product made with traditional manufacturing needs a larger quantity to be affordable

On top of this, your production takes advantage of all the other benefits of additive manufacturing, such as easy integrated assembly, the possibility to create complex shapes and internal channels, etc.

Sculpteo’s Tools for Production with 3D Printing

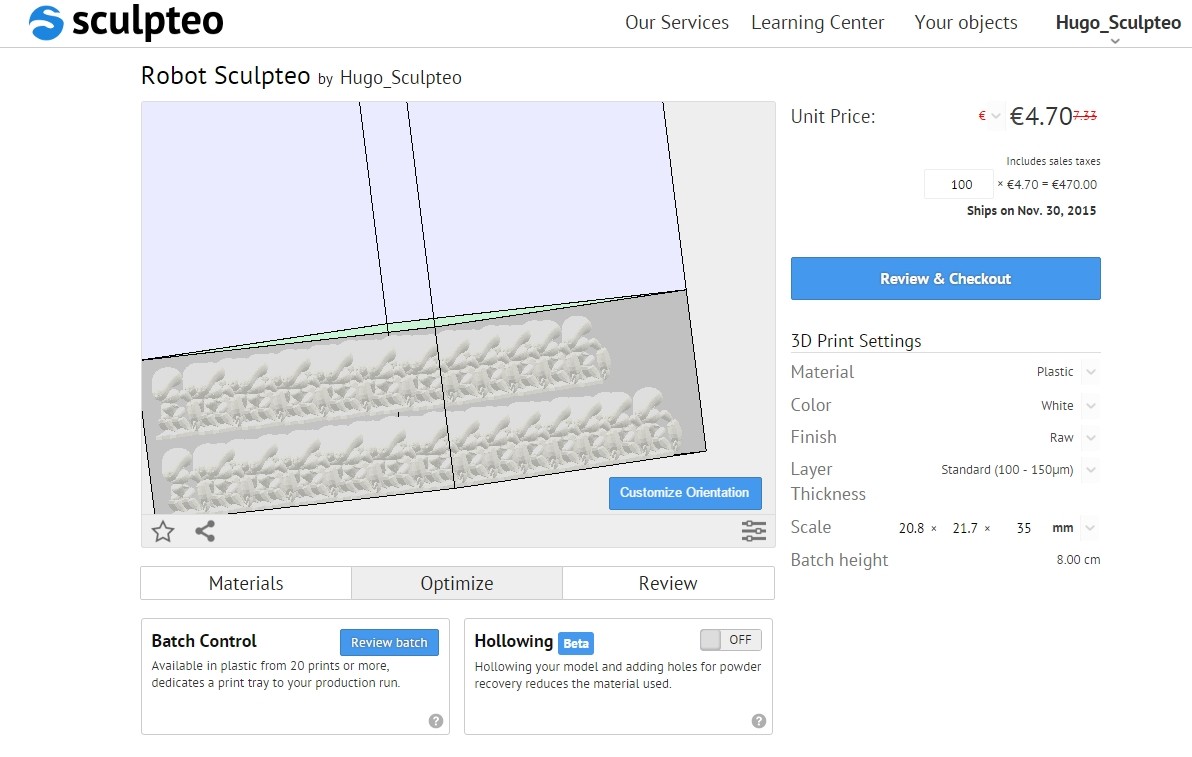

With Sculpteo, you can run your own digital factory from a single product to medium batches. To help you get into production with 3D printing, we offer several options and tools to take control of the manufacturing process:

- Batch Control allows you to reduce the price gradually on orders from 20 units of the same 3D file in plastic. With Batch Control for 3D printing, you can take the virtual commands of our professional 3D printers to customize the orientation, the finishing or the layer resolution directly online. To learn more about the batch control tool, you can visit this page.

- On metal 3D printing, from the second unit of the same object, we offer a discount on quantity.

- On our CLIP resins, you can benefit from price reduction if you order more than 20 units by contacting our sales team.

To be guided into production with 3D printing, you can contact our sales team.

How Businesses Use 3D Printing for Small Batch Production

GE Aviation

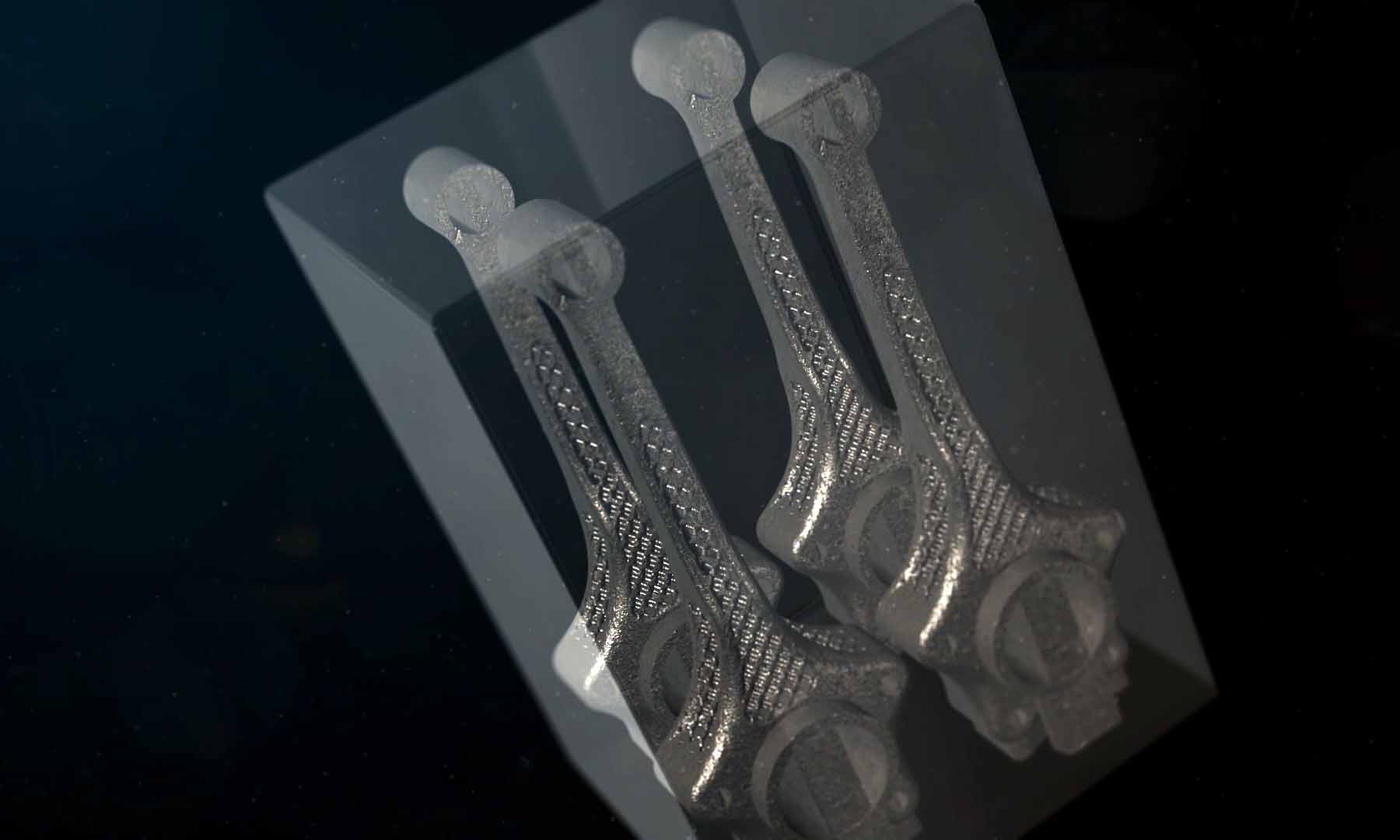

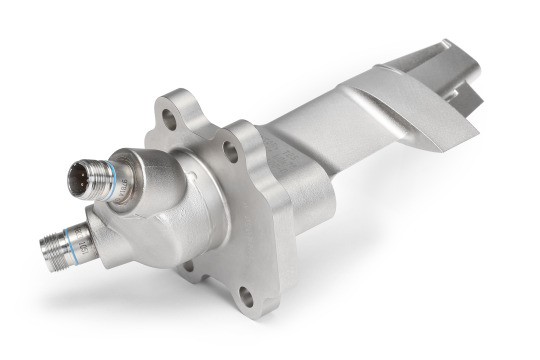

One of the main actor to go into production with 3D printing is GE Aviation. They implement a 3D printed fuel nozzle from an aircraft engine into the production process. This redesign allows GE to skip several assembly and welding steps. The production in batches of this fuel nozzle is made thanks to direct metal printing and make GE save about $3 million per aircraft each year.

The fuel nozzle, 3D printed with Direct Metal Printing

Spinevision

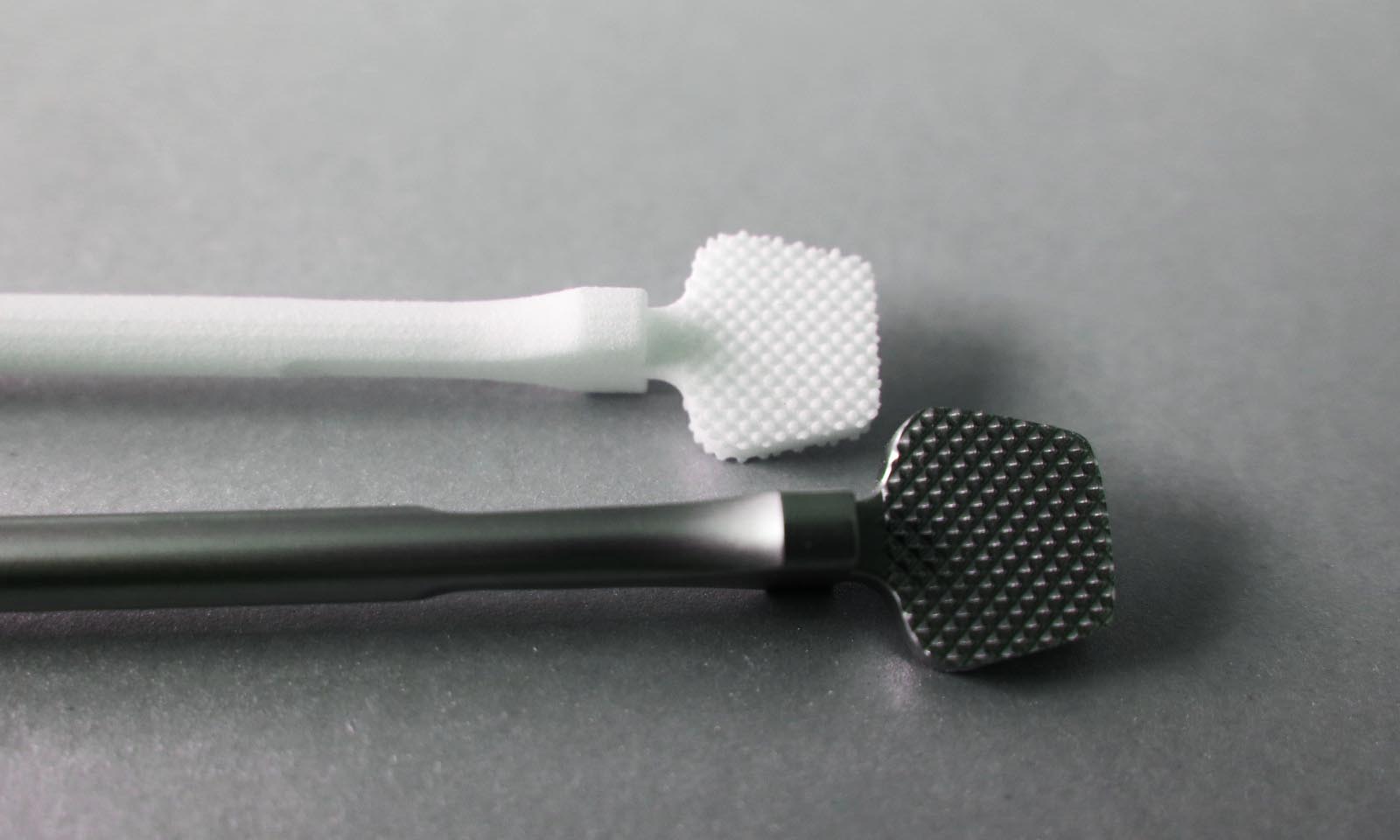

Our customer SpineVision, who design and sell medical implants and medical tools, told us in a recent interview that 3D printing is hugely beneficial for their production chain, and for the medical industry as a whole. Indeed, since they sometimes create very specific objects for very specific pathologies, some of their products are only sold at one unit a year. In such circumstances, small batches production makes much more sense than mass production would: it reduces the cost of stock management.

You can read the full interview about medical 3D printed equipment on this blogpost.

Nanoracing

One of our customers builds drones with our 3D printing service. Nanoracing has used Sculpteo for both prototyping and their production process. Their idea was to deal less with stocks and to outsource the production of some of the parts into our service. For the launch of their first nano drone, Nanoracing created a small series of 300 units, that was destined to experienced drone pilots. This first series allowed them to get a first test of the market, and to grow thanks to the feedback of their first users. This small batch produced with 3D printing was also a tool for their funding process, as the first drones were pledged for on Kickstarter.

You can read the Nanoracing story on this blogpost.

Capturax

This company makes mobile accessories to allow professionals to use their smartphone as a scanning device and a product management tool. To achieve this project, they used Sculpteo for the prototyping of their products through many iterations, but they rapidly considered 3D printing as a sustainable production option for their four first models. They realized that the overall cost of a mold and its lead development time was much higher than small batch production with 3D printing.

Read the full Capturax customer story on our blog.

In conclusion, small batch production allows to reduce the cost of stock managing, to test the market and update your product easier (read this article on Lean manufacturing), and can even be a tool to get initial funding. And it is all made accessible by 3D printing, which makes production as cheap for 10 unit as it is for 10 000. It enables you to experiment more, diversify your products, and take less risks!

If you liked this article, please feel free to share it on Facebook, Twitter and Linkedin

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook