3D Printing Companies :What are the Challenges of Running a 3D Printing Factory?

Posted By Hannah Bensoussan on Apr 5, 2017 | 0 comments

3D Printing is one of the key elements of the era of the factory of the future. 3D printing services make it possible for any person or business with a 3D file to virtually run their own 3D printing factory, distantly, and go from a file to an object, easily, at a moderated cost, and without the need to invest in machines and in their running, maintenance and update.

But what goes on behind this apparent seamlessness? What happens between you upload your 3D file and you receive your object? What are the challenges of running a 3D printing factory? How is it kept up to date? How does it gain in efficiency while providing better and better quality?

Today, we give you an insight into what it’s like to run a 3D printing factory, and the 5 main challenges that need to be overcome.

Premise: What does a 3D printing factory do?

Customers turn to a 3D printing factory with various needs, from prototyping to production, with various levels of knowledge, and a wide range of expectations. In the case of an online 3D printing service, customers need to be, as much as possible, autonomous on the platform, so that they are actually “running a 3D printing factory”, for their own application. If we go back to the basics, what a 3D printing factory does is this:

- It receives a 3D file (in the case of an online 3D printing platform: the file is uploaded on the platform directly by the client)

- It checks, optimizes, and repairs the 3D file if needed

- It 3D prints the model

- It adds the required post-process and finish to the 3D printed object

- It ships the object to the client

- At the same time, it constantly updates its offer and services to increase quality, keep up with the fast-paced innovations of the field

Even though 3D printing is a revolutionary technology and even though 3D printing benefits are many, it remains a manufacturing technique, and when we look at these 6 points, they seem like a pretty straight-forward process. But, of course, at every one of these steps come specific challenges that we’re going to get into.

Better & Faster: The two omnipresent priorities are short lead time and high quality

All of this needs to be accomplished while abiding by the two main priorities: short lead time and high quality. Indeed, customers who turn to 3D printing expect this highly innovative technology to enable rapid prototyping and iterations, to make their production more fluid, etc. They come for the convenience of receiving a part they’ve designed just a few days after ordering it. And, of course, there’s never a question of compromising on quality: on the contrary, as a 3D printing factory, we need to prove every day that 3D printing is a valid alternative to traditional manufacturing, and provides strong, functional parts, with a high surface quality.

Challenge 1: Combining hardware and software

Creating the right digital tools for 3D printing

The first challenge of running a 3D printing factory is that it requires very specific software to enable the functioning of its highly technical hardware (the 3D printers). This software does three main things in one: 1/ it ensures the tracking and operating of the factory, through an intuitive backend, from the reception of the 3D file to the shipping of the 3D printed object; and 2/ it analyzes and repairs the files and optimizes them for 3D printing; 3/ it does so while presenting to the customer an intuitive online platform, that enables them to make the optimization tools their own, and to be autonomous in their orders.

1/ To track the factory’s activity

An efficient production tracking software is the backbone for a 3D printing factory that handles 1000 parts a day while limiting human handling. The interface tracks every 3D file that is ordered, every check-up that technicians have to do on the files before validating them, it optimizes the positions of the parts in the 3D printers – which impacts, directly, the use of raw material and productivity, and because of this, the price. It gives directives to technicians about the post-process steps, and tracks where each part is in the process. It also memorizes the parameters of each 3D printing job, to ensure repeatability, a key element for re-orders and 3D printing series. And, of course, it adapts to each technology, and is different for SLS, Carbon CLIP, Binder Jetting (multicolor 3D printing requires texture, which is handled differently),… The tracking also applies for the shipping time: when ordering, clients choose the regular, fast, or economy mode, and these informations are used to prioritize the jobs and make sure that those who need their parts quickly get them in time.

2/ To analyze and repair the 3D files

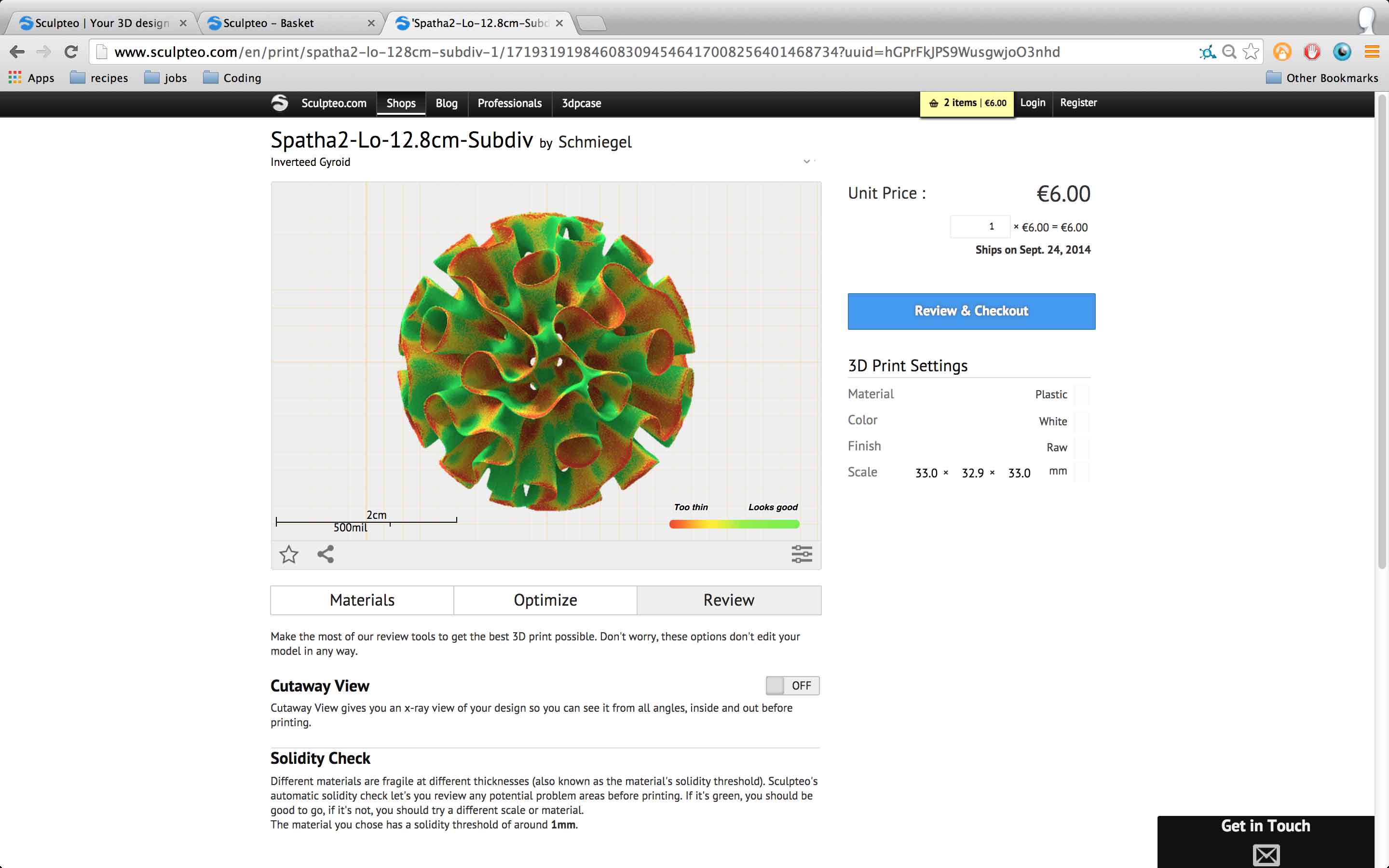

Analyzing, optimizing and repairing 3D files is another challenge, that makes the difference for an online 3D printing service. Because a lot of 3D files are not compatible with 3D printing, it is important that the online platform be reactive, and able to process files with minor defects: holes in the mesh, for example, can be corrected directly when the file is uploaded. The repairing of 3D files is not pure coding, and requires strong mathematical knowledge. Once on the 3D printing platform, we offer other optimization tools: the solidity check shows the area where the model might break, the thickening tool thickens areas that need to be, hollowing enables to reduce the price of the 3D print by removing excess material, and the list goes on. While using these tools, the customers of course see their 3D printing quote updated automatically. These tools are a real added value to make the customers autonomous on the platform.

3/ To create an intuitive platform

Lastly, the intuitive front-end needs to make the link seamlessly between the customers’ practices and the directives given to the front-end. It also helps the client follow their order, as we know that lead time is essential.

After stating all of this, it is clear that a 3D printing factories needs a highly-skilled development team, and that part of it needs to be dedicated to software R&D.

In the case of Sculpteo, AMT, the Agile Metal Technology tools suite, whose first tool is Business Case, the 3D printing AI, is, in a way, an ongoing crowning achievement that represents our software R&D team’s hard work.

Challenge 2: 3D Printing means permanent renewal!

Widening the range of 3D Printing materials and finishing options without diluting our focus

In order to always meet the customers’ needs at the closest, and to showcase all the possibilities of 3D printing, it’s important to widen the offer, and keep up with the latest 3D printing materials and technologies. When Sculpteo started, we focused mainly on white polyamide 3D printing, with the SLS technology. But we progressively widened our range of 3D printing materials and technologies, to now offer more than 75 options, from plastics and resins to metals, with seven technologies (SLS, Polyjet, Carbon CLIP, Binder Jetting, DMLS, SLM, and metal wax casting). We also extended our finishing offer for a better and better surface aspect, with the smoothing beautifier developed by our R&D team, as well as polishing, painting, varnishing and dyeing.

This is a challenge on several levels:

1/ Keeping up with the market’s new possibilities

Meeting the customers needs means knowing the customers needs, and for that we have to constantly be attentive to the market, and have an extremely skilled customer relationships service.

2/ Being part of 3D printing innovation – Material R&D

The importance of material research and development cannot be stressed enough. Because the technology is permeating more and more activities, being used for more and more applications, we can’t “just” offer to our clients what the market has in store. We need to be a part of the market’s evolution and progress, it is essential to offer ever-renewed possibilities. I’ll keep with the example of Sculpteo: the smoothing beautifier finish that we developed is a way to make 3D printed objects more closely comparable, in their surface finish, to injection molded objects, by removing the rough aspect and touch of SLS 3D printed objects. This is, in a way, a frontier to conquer for 3D printing. And there are many other 3D printing frontiers to explore!

3/ Updating our skill set when we update our offer

When we add a new technology to our online 3D printing service, it means adding a whole new set of skills to our team: learning how the machine works, how to add it into the production flow, and what design limitations go with it. And because the technologies of 3D printing are very diverse, it means adapting constantly. To give just two examples among may: some technologies (polyjet, CLIP, metal melting) require supports, which means support removal in the post-process, and some don’t (SLS, Binder Jetting). Some technologies require infiltration in the post-process (for multicolor 3D printing), and some don’t.

4/ Finding balance

There’s a balance to find between diversification and focus, which is not specific to 3D printing but is worth mentioning. Keeping our high-standards and mastery of the technologies we’ve known for a long time, while fostering this mastery in the ones we add in; and not lose sight of the short lead time priority: there’s a risk of diluting the attention and being less efficient when adding in a wide range of materials.

Challenge 3: The delicacies of 3D Printers

Adapting to the particularities of the 3D printing field: working with 3D printers

3D printing is relatively new, dating back from the 80s (you can read about it in our “History of 3D printing”), and it is based on a culture of prototype and iteration. Every 3D printer was invented by a person passionate by innovation, and each 3D printing technology has its unique properties that derive from its first prototype. 3D printers construction is not the most formalistic of fields. This means that for every constructor, we need to adapt to the subtleties of the machine, whether it is in terms of parameters, heating and cooling, or else.

The second point of the “working with 3D printers challenge” is that 3D printing innovation is still booming, and the machines evolve constantly, with productivity boosts that are impressive from one model to the next. For example, because of its different handling of temperature regulation, the SLS 3D Printer P396 is 30% more productive than its predecessor the P395! This means, as you would expect in the 3D printing field, always keeping ourselves at the cutting edge of the technology.

Challenge 4: Meeting the clients’ expectations, just with their 3D file

Adapting to the particularities of the clients: working with no other technical specifications than a 3D file

A specificity of a 3D printing factory is that clients who upload their 3D file, most of the time, don’t give us other technical specifications than this 3D file. When in traditional manufacturing, clients come with a design brief, requirements specifications and an explicit set of expectations, in additive manufacturing, at least when we work as a service, we get a 3D file, and the two tacit expectations that I’ve mentioned several times: short lead time, and high quality. Of course, there are exceptions, and we are always attentive to clients who give us specifications directly, but because our added value is the possibility for the client to be autonomous, we try to minimize as much as we can the back-and-forth with the customer service, and the costly iterations that would increase the 3D printing price for the client, and take too much time.

That’s where the analyzing and repairing tools that we’ve talked about are essential, as well as the correct information provided to the client.

The technicians need to be highly reactive and to either anticipate what the client wants by deduction, or be able to provide the right information to explain why a 3D file will have an issue when 3D printing, so that the customer service can get that information out as quickly as possible. Sometimes, the issues (an area will be highly fragile) are designed on purpose (this area is a support and will be broken by hand), and technicians need to be able to identify these situations.

Challenge 5: Training competent 3D Printing technicians

Our last challenge is far from being the least, and is well introduced by the ones that precede it: a 3D printing factory needs competent 3D printing technicians, who need to be able to handle the 4 other challenges I’ve explained.

Since the demand for these skills is only starting to be visible to educators, universities still have very few trainings in the 3D printing field. So we train our technicians to our specific process and our specific tools.

Which skills do the 3D printing technicians need to have?

1/ Because they handle industrial 3D printers, they need to have mechanical and electronical knowledge

2/ They practice preventive operations (cleaning, updating of elements) and curative operations when repairs are needed. This requires adaptability, since they interact with the different 3D printer producers, and with the different interfaces.

3/ As I just explained, they handle the 3D files, and need to have CAD knowledge and strong knowledge of each 3D printing technology and process in order to know if a file is possible to 3D print.

4/ And of course, high reactivity is key: the technicians need to do the most exhaustive feasibility study possible in the shortest time possible, for each one of the 1000 parts they check a day.

To read more about 3D printing education, read our “Graduate in 3D printing” free ebook.

Here we are with the 5 challenges of running a 3D printing factory. If you want to learn more about our 3D printing service, discover our 3D printing materials here, or upload a 3D file directly here.

You can also discover our laser cutting service here.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook