3D Printing Material: Multi Jet Fusion PA 12 is Now Available For All!

Posted By Hilmiyati Kusnadi on Jul 26, 2017 | 1 comment

We are proud to be one of HP’s first French partners to work with their 3D printing technology, HP Multi Jet Fusion. After almost three weeks launching this material as part of our BETA Program, today we bring good news for those who are waiting to experience 3D printing with the newest HP technology: 3D Printing material HP Multi Jet Fusion PA 12 using Jet Fusion technology is now available for all!

Discover this new technology and material, and find some design guidelines to start your 3D printing project with the fastest plastic 3D printing technology!

3D print your parts up to 10 times faster with HP Multi Jet Fusion.

Multi Jet Fusion is a 3D printing method that creates parts through a multi-agent printing process. During the 3D printing process of your object, a print head deposits a fusing agent on a powder bed, then followed by drops of a detailing agent to create fine details and smooth surface. The area is then exposed to an infrared light in order to make these agents act on the material to create the objects.

Either to create a prototype or to manufacture a final product, the Multi Jet Fusion technology is the perfect choice for you. In comparison to the FDM or SLS technologies, the Multi Jet Fusion process is the fastest plastic 3D printing technology. Indeed, it accelerates your 3D printing process time up to 10 times.

The reason that makes this technology so much faster is that the 3D printing process uses less heat to fuse the material, making the cooling time quicker. Once the 3D printing process is done, the building box can be removed from the 3D printer to cool the parts outside of the printer and the next production batch is ready to get started. As a result, you don’t have to stop the production.

Multi Jet Fusion PA 12 is now available for all!

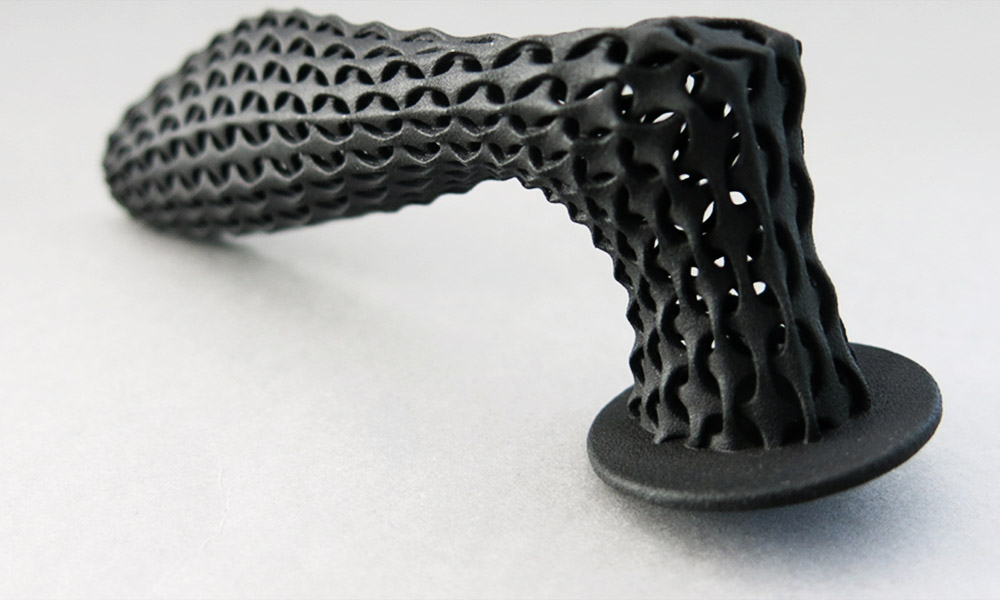

We are making our Multi Jet Fusion PA 12 available for everyone. There are several things that you need to know before deciding to try this new 3D printing material. The object 3D printed in Multi Jet Fusion PA 12, made from polyamide powder, has a good elasticity and high impact resistance. It’s also particularly resistant to chemicals such as hydrocarbons, ketones, mineral bases, detergents, aldehydes, oil, and fats.

Multi Jet Fusion PA 12 allows you to create very complex shapes in a short period of time. This polyamide material is suited for the application that requires high resistance to scratches and abrasion, adaptable to every weather, being UV, and light stabilized. Moreover, objects 3D printed with this polyamide material can be used for a wide range of applications in the mechanical, electronics, medical and automotive industry.

For now, you can only get unpolished 3D printed parts for this material on our online 3D printing service. However, the surface is already relatively smooth. Multi Jet Fusion PA 12 is a great material either for beginners and professionals, it allows you to create high-quality 3D printed parts at an economical cost.

Some guidelines to 3D print your parts with our Multi Jet Fusion PA 12.

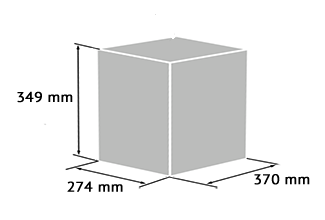

We use the HP Multi Jet Fusion 3D 4200 to 3D print your parts in which this 3D printer technology allows to print with a layer thickness of 80 µm (0.08 mm) in a building volume of 274 x 370 x 349 mm (10.8 x 14.6 x 13.7 in).

The technical properties of Multi Jet Fusion PA 12 vary depending on the thickness of the model. With a minimum wall thickness of 0.6 mm, your 3D printed object becomes more flexible. To make the object become fully rigid, a 2 mm wall thickness is required.

Learn more about the design guidelines of your 3D printed parts in this dedicated page of Multi Jet Fusion PA 12.

Providing you with the best 3D printing software tools is one of our missions to help you achieve the best quality and experience in additive manufacturing. Before finalizing your order, benefit from our 3D printing software tools to help you edit and improve your model.

Multi Jet Fusion PA 12 is the first material available for the Multi Jet Fusion Technology. Wondering what will be the next material coming to 3D print your project with this HP technology? Keep up-to-date and subscribe to our newsletter to get some updates on HP material or technology and news related to the 3D printing universe!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook