Flexible Plastic for 3D printing: PEBA is available at Sculpteo

Posted By Hilmiyati Kusnadi on Aug 2, 2017 | 2 comments

At Sculpteo, we never stop to innovate. Providing you with the best online 3D printing service is our goal, that is why we complete our service with a set of online 3D printing software tools and launched several new materials, as well as upgrades on our existing ones for the past weeks. After HP Multi Jet Fusion PA12, we proudly present you a new flexible plastic for 3D printing: PEBA.

In this blogpost, discover all you need to know about this new flexible material, the technology used, its benefits and applications and some tips to help you design your 3D model for PEBA 3D printing.

PEBA: Our flexible plastic for 3D printing

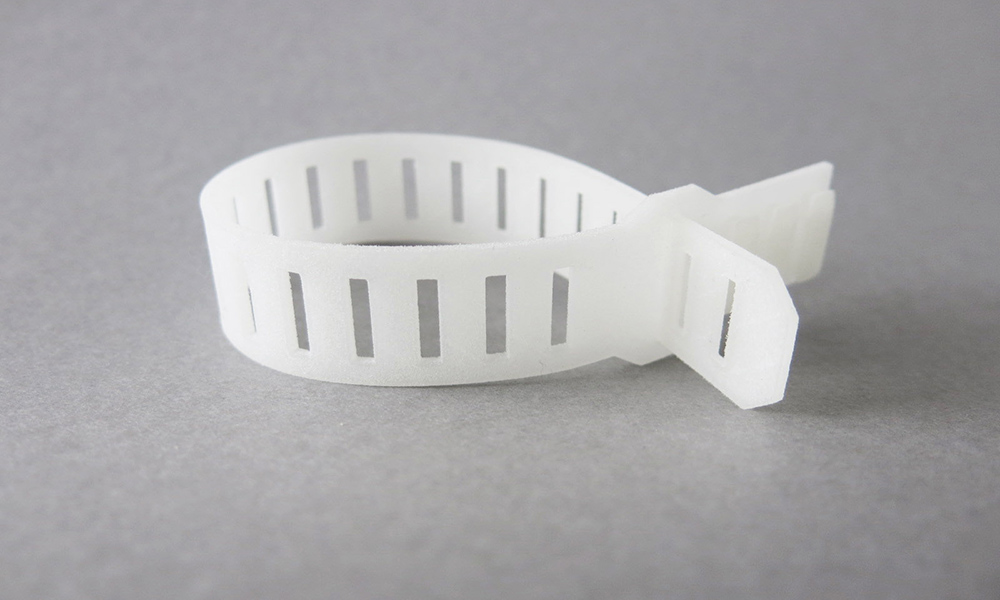

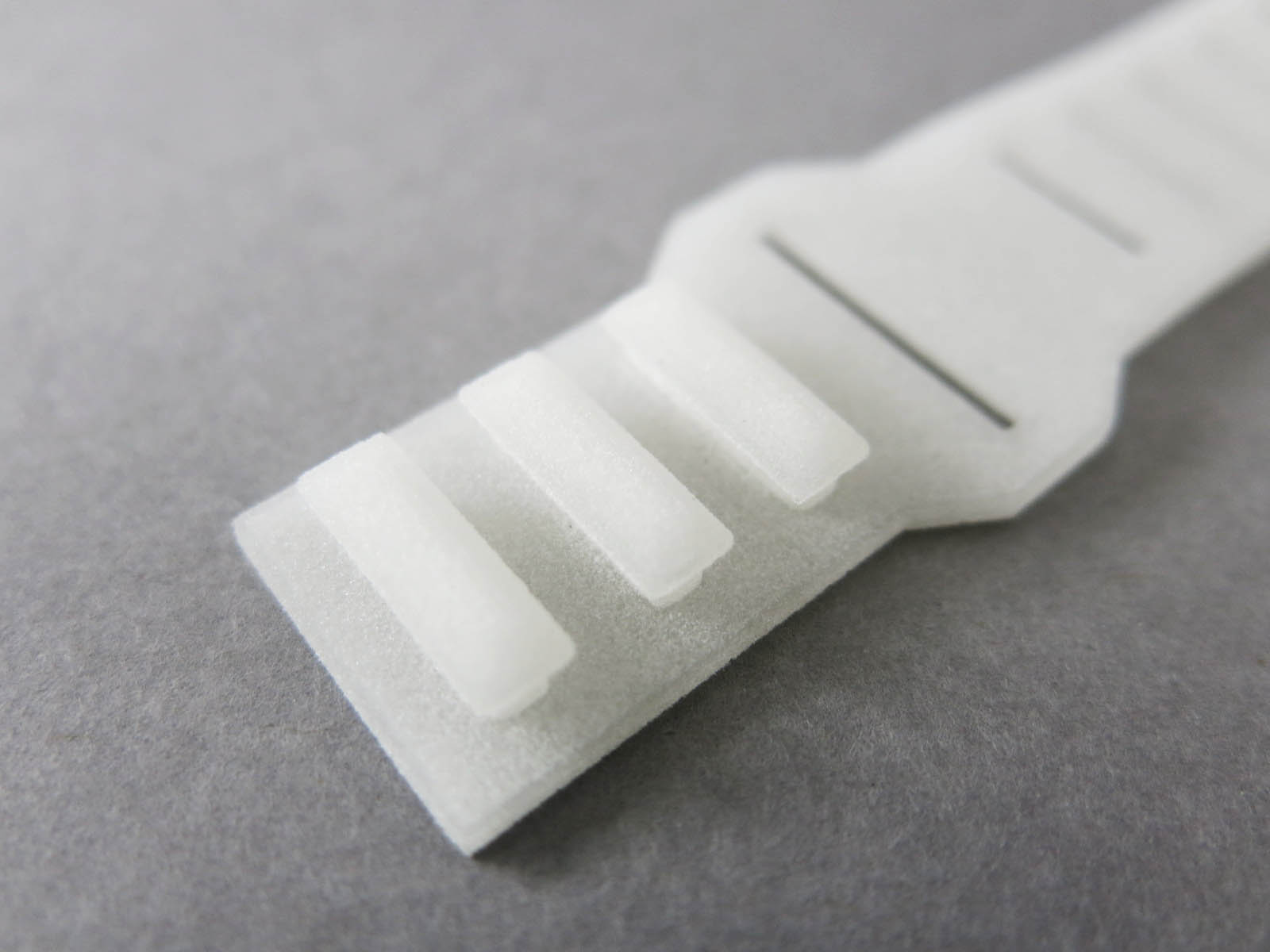

Your object 3D printed using our PEBA 2301 (Polyether Block Amide) material is created from a fine polyamide powder. Using the process of Selective Laser Sintering (SLS), this material has a rubber-like aspect which makes it rather flexible but solid and resistant to stress and fatigue. The surface of raw PEBA is white, granular and somewhat porous.

This flexible material is great to use for both, beginners and professional designers because of its high precision and low-cost.

Finishing option available for this flexible PEBA material

We only deliver our PEBA material with a raw finish option. During the 3D printing post-process, your 3D printed object is sandblasted but not polished. The surface remains slightly granular and porous, but it will fit most of the applications that require high elasticity and strength.

What are the benefits and applications of the PEBA material?

This new 3D printing material has a good chemical resistance and excellent long term stability which makes PEBA a great technical material. Durable and with a rubber-like behavior, PEBA is great either for prototyping and production. This material allows you to create footwear material, sports equipment, medical supply tools or automotive parts. Moreover, our new material can also be used for hand braces, insoles, grippers, handles and seals.

How long does it take to 3D print your PEBA part?

Once you upload your 3D file to our site, our platform calculates the cost of your 3D printing order automatically. The cost can be based on the options chosen such as the size of your object, our batch control option, the weight of your object, also the shipping option chosen. Moreover, our flexible 3D printing material PEBA can be shipped worldwide within 6-9 business days.

Some guidelines to help you 3D print your parts with our PEBA material

Sculpteo uses EOS Formiga P100 to 3D print your parts. This 3D printer allows to 3D print with a standard layer thickness between 100 – 150µm. The maximum size of your object should not exceed the physical size of our 3D printer bed which is 315 x 240 x 190 mm. If your 3D object is larger than that, it cannot be 3D printed.

Discover more about the design guidelines and technical specification of PEBA in this material page.

Now it’s your turn to create the next innovations thanks to 3D printing. Upload your 3D file and benefit from our 3D printing software tools to improve your 3D design.

Subscribe to our weekly newsletter and be the first to receive the news related to our new materials and technologies and keep up-to-date with 3D printing news!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook