3D printed bridge: The most impressive structures!

Posted By Lucie Gaget on Jan 17, 2018 | 0 comments

Thanks to the additive manufacturing technology, we are now able to build impressive structures at an architectural scale, such as bridges. Indeed, new technologies, 3D printing materials and printers are making it possible to build urban features with brand new processes. For example, large scale and concrete 3D printers are making their entrance on the market. They are allowing to 3D print houses or any concrete structures way faster and cheaper than with other traditional processes. The construction sector starts to make the most of this cutting edge technology. Nowadays, it is even possible to build a real 3D printed bridge! Some of them are just projects, but other ones are already built and you can see some of them all around the world.

In this blogpost we are going to see all the benefits of additive manufacturing when it comes to construction. Then, we chose to show you the coolest 3D printed bridges that you could see, or walk on. From concrete to steel bridge, everything is possible. Follow the guide!

3D printing in the construction field

The additive manufacturing technology has a lot of advantages for diverse sectors such as the medical industry, architecture or even the music industry. For the construction sector, this technology is becoming a great asset. Here is why this technology is being more and more used:

3D printing reduces costs

Additive manufacturing is a great way to get a cheaper process. But how, exactly? First of all, when you are using 3D printing, you only use the amount of material that you need for your production. It is obviously reducing the waste of material and the costs. More specifically, when you use the additive manufacturing technology in construction, you save labor costs. You just need a 3D machines to do the building job.

You can build faster with additive manufacturing

Indeed, building architectural features can be time-consuming, but additive manufacturing is giving the possibility to get a faster process. A machine can easily work continuously, and the time that you can save by using this method is impressive. Even for product development, it is quite helpful. If you need to do prototypes or miniatures, it appears to be fast and easy. In the end, it is even possible to get a real 3D printed bridge or 3D printed house in only a few hours instead of a few months. It is also quite easy to make a 3D model of your future construction, that you can work and rework on until you get the final desired shape.

3D printing is allowing to make new experiments

Additive manufacturing is a cutting edge technology. Researchers and engineers are using this technology to make various experiments. Indeed there are always pushing the boundaries of these new technologies in order to show what it could be possible to do with it, and how it could change traditional processes. It leads to impressive experiments, to see what are the larger structures constructible, what are the different materials that can be used for additive manufacturing, etc. It really allows to do architectural experimentations and find new techniques.

Additive manufacturing offers great design possibilities

Last but not least, 3D printing is a good technique to work efficiently on designs. As we said before, once you have a 3D model, you can modify your project as much as you want using a 3D modeling software. Indeed, additive manufacturing is giving a lot of freedom when it comes to design. It is really possible to create simple and complex geometries, and to give life to the craziest and most impressive designs. For example, with injection molding, it can be complicated and expensive to create complex objects. This problem doesn’t exist with additive manufacturing, that’s why bridge designs could be improved with this manufacturing technique.

In addition to all of that, we can say that this technology is evolving fast. Possibilities are becoming endless and new 3D printing materials are developed everyday. Even if concrete 3D printing is growing and adding new perspectives to the construction field, 3D printed urban structures are not necessarily made with concrete. Indeed, steel and plastic are also used! Let’s see how these structures are made.

The 3D printed bridge is becoming a reality

How to print a large scale structure?

In order to 3D print a large scale structure, you will need to use a large scale 3D printer. As we saw during the last edition of the trade show FormNext, printer manufacturers are unveiling a lot of new technologies and efficient 3D printers. More specifically, they are making more and more large-scale printers. Additive manufacturing appears to be efficient to print a lot of objects and projects, but now that we know how useful and efficient this technology is, it should be possible to print huge projects in just one part.

For this kind of projects, new technologies have to be developed. To build big structures, the printers have a crane and automated arms. These 3D machines can print any big project on spot! These printing machines look like the one that you can see on the picture below, and can sometimes be even bigger.

Credit: Adriaan de Groot

Metal 3D printing, concrete 3D printing, and large scale printers, all possibilities to create urban architecture are already being developed. Civil engineering is being helped by amazing new processes. Now, we will see how it is possible to print a bridge.

3D printing a bridge: how does it work?

How is it even possible to 3D print a bridge? Is the printer going against gravity? As these kind of creations are impressive, a lot of questions are directly coming in mind.

Obviously you can’t build architectural features or urban structures with any 3D machine, it requires a large scale 3D printer. Moreover, the final structure has to be strong! For the moment it seems a bit more doable to print pedestrian bridges than structures for big roads and heavy automobiles. But it could become a reality faster than we can think.

To get strong structures like bridges, the construction has to get a lot of layers and it often has to be reinforced. But it also depends on the materials that you are using. Regarding the different materials you can use to build large scale structures, the choice is yours. Some of the printed bridges that we will see later in this blogpost are concrete bridges, or steel or plastic 3D printed structures. Obviously, it depends of the final goal of your project. A pedestrian bridge has to be strong and support a substantial weight, that’s why most of the time these bridges are printed with reinforced concrete, or Stainless Steel. For a decorative bridge, you can use the material that you want, it is possible to print it with plastic if you have the technology to do it!

There are two different methods to build such a structure. First, the bridge can be printed in different parts, and then assembled. Or it can be built on spot thanks to big 3D machines with robotic arms. Robots completly enables the construction of these infrastructures, from concrete to metal bridge.

The researchers of the MX3D team, that are actually working on a 3D printed bridge project, even developed a robotic 3D printer that can be placed directly on the bridge to print it. Once the first part is printed, it can be placed on this first 3D printed part of the bridge and it will continue to build the rest of the bridge!

What are the existing constructions?

Let’s see what has already been made in the construction field regarding 3D printed bridges.

- The world’s first 3D printed bridge for cyclists

Dutch cyclists now have their own cycling bridge, and thanks to Eindhoven University of Technology and BAM Infra, it is printed. This concrete 3D printed bridge comes from the Netherlands. It is a solid structure, its designers says that it could handle the weight of 40 trucks! This is not a huge bridge, but it is impressive as it looks like any other bridge and it is standing over water. It took three months to build the whole bridge and 800 layers of concrete were needed to reach this quality and this solidity. Reinforced prestressed concrete was needed to get to this result. The primary goal was to create a sustainable structure, strong enough to be daily used by cyclist and pedestrians.

Here is a picture of this 3D printed reinforced concrete bridge, and it is quite a success.

Image: BAM Infra

The BAM Infra and the Eindhoven University of Technology used concrete blocks and then assembled them, in order to create this bridge.

- 3D printed pedestrian bridge in Madrid

Here is another example of concrete 3D printed bridge. This concrete bridge has been built in Madrid, Spain. This bridge is 12 meter long and is printed in micro-refined concrete, and reinforced with thermoplastic polypropylene. It has been designed by The Institute of Advanced Architecture of Catalonia. This bridge is made of eight different parts. The Institute of Advanced Architecture of Catalonia has been working on additive manufacturing and large scale structures for more than 15 years now.

The project here was to create a sustainable bridge, with an organic design, in order to preserve the natural aspect of the park.

- 3D printed bridges in Shanghai

In China, the School of Architecture and Urban Planning of Shangai’s Tongji University printed two bridges beside the entrance of the school. There are a little and flat bridge, and another one, with a bigger size and some steps. They are both made with 3D printed plastic.

The longer bridge is 11 meter long, and the small one measures 4 meters. They have been created in 360 hours thanks to 3D printing modules, robots and drones. The bridges designs are interesting, they are nice and complex structures. They are precisely showing the designs possibilities offered by additive manufacturing.

It is important to notice that these bridges are only for display for the moment.

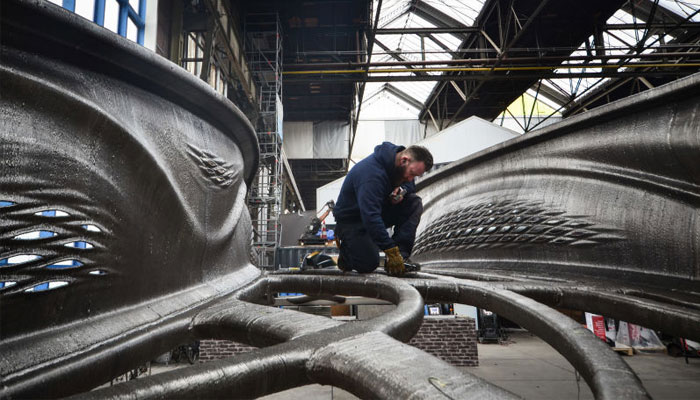

- MX3D and the metal 3D printed bridge in the city of Amsterdam

MX3D and Joris Laarman Lab developed an impressive robotic additive manufacturing technique. Metal 3D printing is evolving quite fast, and some machines are now totally able to 3D print metal at an architectural scale. Here is the proof with this bridge. It is still a project, this Stainless Steel bridge is built in different parts and will be completely finished in june 2018 but it is already on a good way. This bridge will be placed right over a canal of Amsterdam, the Oudezijds Achterburgwal! It will be the largest 3D printed metal structure ever created.

Is this metal bridge for Amsterdam expensive? The co-founder of MX3D Gijs van der Velden told that this MX3D bridge, using a new building technique and allowing more freedom for the design, is the same cost for the city of Amsterdam, than a traditional bridge project.

Olivier De Gruijter

The Amsterdams canals could be onamented with great concrete and steel bridges in the future. To see the construction process of this bridge, you can watch the video below:

This project is a demonstration, to show a brand new technology, made by the MX3D team. They created a brand new 3D printer and they even developed a software to control it.

These bridges are the world’s first 3d printed bridges, there will be more to come in the upcoming years!

The future of 3D printing for construction

Additive manufacturing is not the first thing that comes in mind when you think about construction, but this technique is becoming more and more widespread. This technology could totally change the building processes that we know in the upcoming years, and it could be useful in various situations.

For example, as the 3D printing process is fast, it could be an interesting method to reconstruct parts of cities affected by natural disasters. Automated construction could be a great solution for these kind of situations. Stainless Steel or reinforced concrete bridges created thanks to 3D printing could be more and more common in the future.

We could see even more astonishing designs in the street, with more organic and lattice structures for instance.

We hope that you enjoyed to discover these amazing creations and that you understand better all the benefits of this technology to create these important and customized structures.

If you are interested in the use of additive manufacturing in the construction sector, we have an article about 3D printing and architecture for you. And if you want related stories about concrete 3D printing, check our blogpost about concrete 3D printers.

If you want to stay up to date regarding the latest news of the 3D printing world, subscribe to our weekly newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook