5D Printing: A New Branch Of Additive Manufacturing

Posted By Jessica Van Zeijderveld on May 7, 2018 | 0 comments

3D printing has already been around for quite a few years. Then, a bit more than a year ago, talks of 4D printing started to circulate – which we have wrote an in-depth blog post on as well that you can read here. But now, the idea of 5D printing is being talked about and experimented with. 5D printing is not an evolved version of 3D or 4D printing as it is with audiovisual aspects of different dimensions – it is less complicated than that. You can see 4D and 5D printing as roots originating from 3D printing. In this blog post, we will first explain to you what 5D printing is, then we will tell you what the benefits are and how it can be applied. Last but not least, we will tell you what the differences are between 3D, 4D and 5D printing along with how you can keep up with the latest technological advances related to additive manufacturing.

What Is 5D Printing?

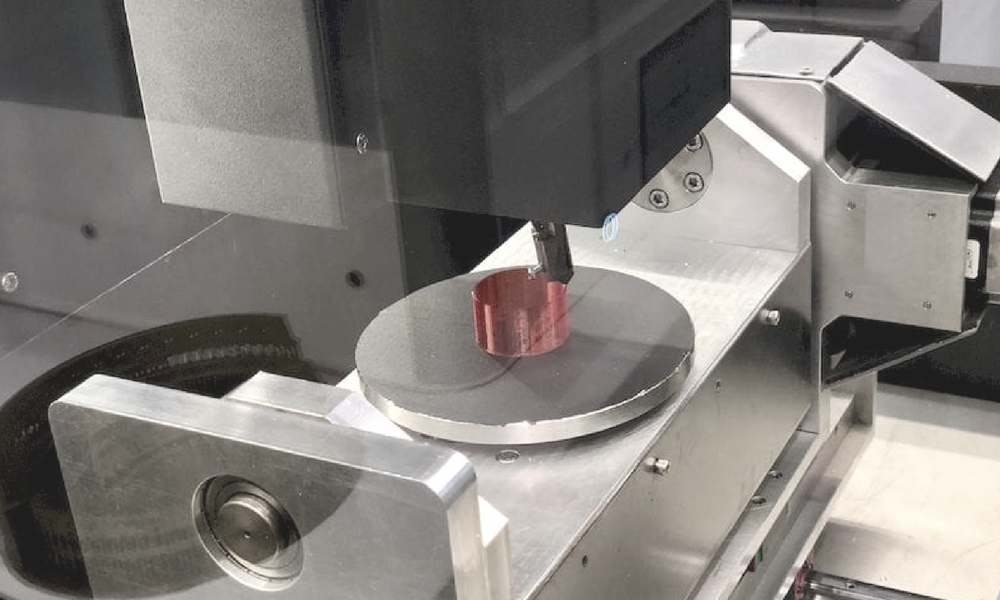

About two years ago, the first talks around 5D printing started to circulate in American Universities but one company had actually implemented this new technology partially, namely Mitsubishi Electric Research Labs (MERL). William Yerazunis, Ph.D. Senior Principal Research Scientist of this lab explained: A 5D printer allows for objects to not be printed from one point upwards but from five axes. Hence, where the number five in 5D comes from. The printhead moves around from 5 different angles while printing because the plateau on which the object gets printed moves as well. These movements allow for the printer head to come in from many different angles, otherwise not achieved with 3D printing. These new angles result in the printing head being able to follow the path of the object’s shape and outline. By not having to follow a straight path on a static plateau – and using the shape of the object instead, the printed parts can be created with curved layers instead of flat layers. These curved layers allow for stronger parts that have a complex design to be printed.

Below, you may find a video of an innovation award-winning 5D printer created by Indian engineers:

Benefits: Stronger Complex Objects Made With Less Material.

Regular 3D printing can somehow restrain the design of objects because objects that are 3D printed are technically made out of slices of flat layers. Because the layers are flat, the object can have some weak points. With 5D printing, the curved layers prevent creating weak points. Tests that have been made with 5D printed objects by MERL showed that these objects were 3 to 5 times stronger than if it had been 3D printed. MERL explained the difference in strength by comparing a bicycle to a motorcycle. MERL pressurized two identical plastic printed pressure caps, one created with 3D printing and the other with 5D printing. The 3D printed cap could only handle 0.1 megapascals of pressure – so, about 1 second before it burst. The 5D printed cap could withstand 3.7 megapascals before bursting. So, like we said, this has to do with the fact that normally 3D printing creates objects in horizontal layers, and these layers can sometimes create weak points. When there are forces pushing the opposite direction of the direction these layers have been printed – which can be down, up, through etc. – layers would have to be parted from each other. This force and the enduring of these forces of the materials result in creating a stronger object. Another major benefit of this new technology is it uses 25% less material compared to 3D printing.

Below, you may find the video of the stress test between a 3D and 5D printed pressure cap:

How Can 5D Printing Be Applied?

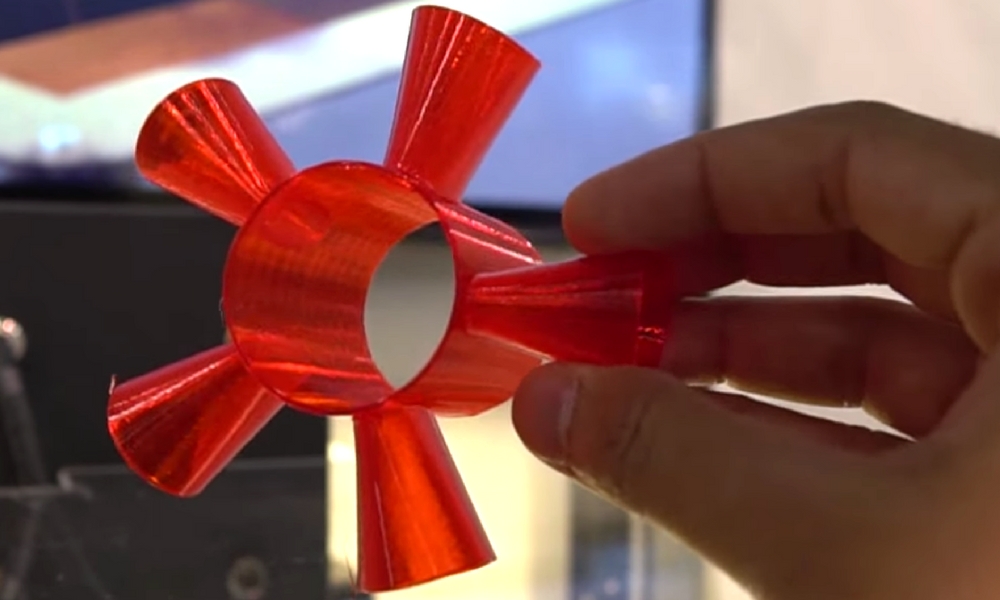

The nature of 5D printing is a combination of subtractive and additive techniques. According to MERL, 5D printing does require quite some analysis beforehand on how the 5D printed parts will be used. So, the best way 5D printing can be implemented is for complex structures and designs that require a lot of strength. Think of specific parts such as when Mitsubishi uses it for motorcycles parts or for companies in the construction industry – items that need to be strong in order for it to be functional in the industry due to these items needing to follow industry guidelines and safety regulations. You can think of 5D printing, for example, a concave cap, an item that could not be 3D printed because it needs a lot of fillers and support, plus whose design is too complex. Below you can see an example of a 5D printed concave cap and you will directly understand how the shape didn’t allow for horizontal 3D printed layers.

Differences Between 3D, 4D, and 5D Printing

The easiest difference to explain between 3D and 5D printing is that 5D printing has a moving plateau that allows for the printhead to make different angles from five dimensions and create curved layers whereas 3D printers create flat layers on a fixed plateau. The rest of the process is the same in general. Both processes make use of a 3D scanner, the same kind of 3D design, 3D file and 3D printing materials.

4D printing is the one that is most different out of all 3 processes because it relies on different kinds of materials and different kinds of 3D models. This technology uses programmable materials that change their function when hot water, light or heat is added to the mix. The input is a “smart material”, that has thermomechanical properties and other material properties – attributes that allow for shape change and are different from the common 3D printing materials.

Where To Read About Other Technological Advances?

4D and 5D printing are only the latest roots that came out of additive manufacturing but there are surely more to come in the future. At Sculpteo we wish to give our clients and readers all the information on these new processes and explain to you how you can apply this for future reference. If you wish to keep yourself up to date, you can read our blog, subscribe to our newsletter or follow us on Facebook, Twitter, and LinkedIn. Each of these channels will supply you with the latest news regarding 3D printing and its many benefits!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook