Top 6 trends that will have a major impact on the 3D printing industry

Posted By Jessica Van Zeijderveld on Jun 26, 2018 | 0 comments

It’s been two weeks since the release of our 2018 edition of the State of 3D Printing. In this fourth part of this series on analyzing the State of 3D printing, we wish to outline the key impact points on the 3D printing industry with the help of our 1000+ respondents who gave us all the insights on material usage, profile hiring, 3D printing applications and many other 3D printing related aspects. Find out below how you can prepare yourself on the development of this industry and see how it will affect the near future.

#1 Increase in expertise

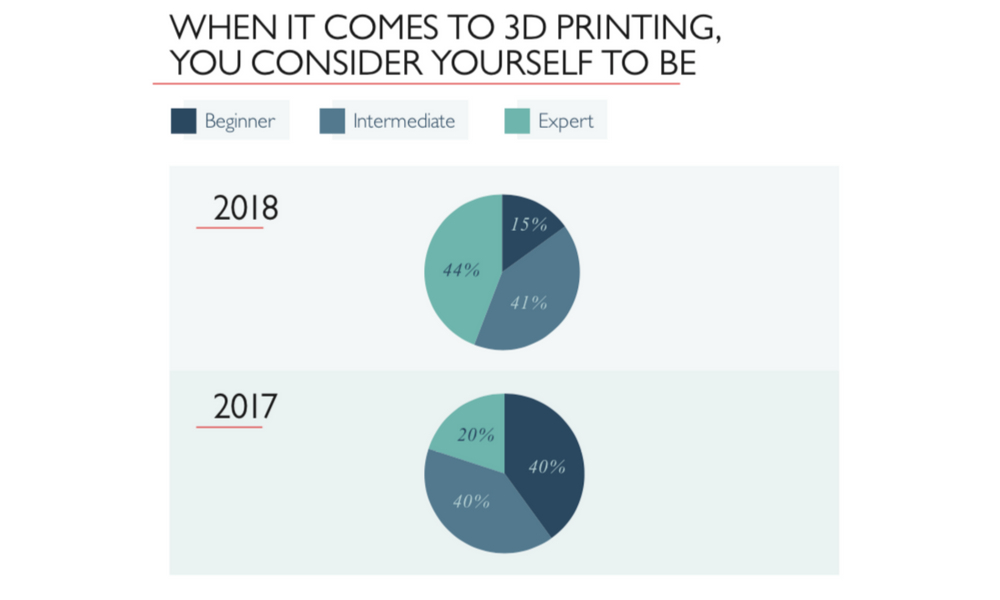

In our third part of our series on analyzing our 2018 edition of the State of 3D Printing, we saw a major shift in the level of expertise from our respondents. This year, 15% think of themselves as beginners, 41% see themselves as intermediates and 44% see themselves as full-on experts whereas 40% of last year’s respondents thought of themselves as beginners, 40% intermediates and only 20% saw themselves as true experts on the additive manufacturing technology.

3D printing users have become more skillful with 3D printing over the year. This new development will transform into a fact that these users are moving out of their current comfort zone – now that more people are familiar with the current state of the 3D printing technology – and experiment more with 3D printing applications such as using new forms of 3D printing. In order to adjust to this trend, companies need to get on or get off on this train regarding new experimentations and applications of 3D printing. Innovative ways are the keys to keeping your head above water.

#2 Increase in metal 3D printing

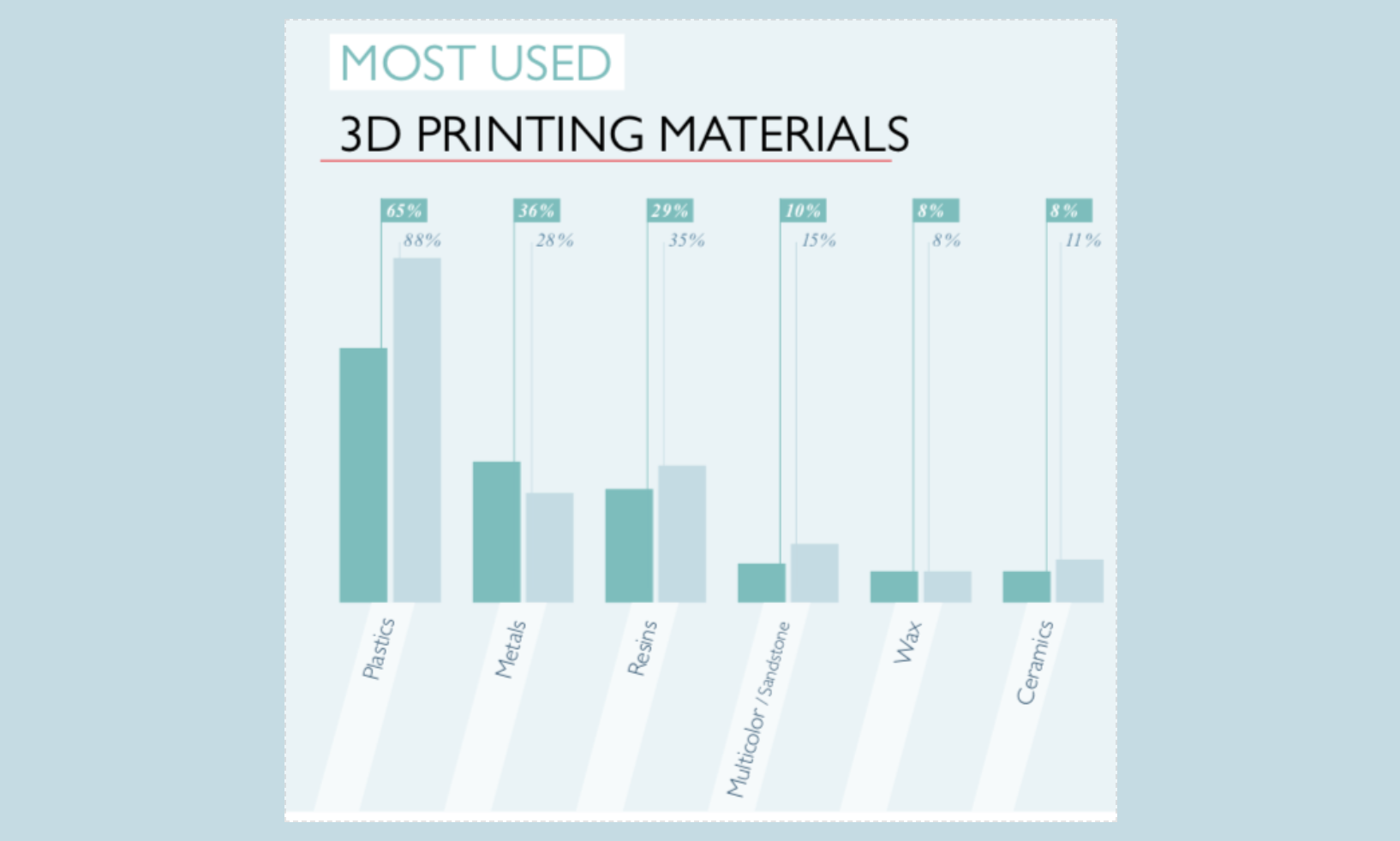

In our second part of our series on analyzing our 2018 edition of the State of 3D Printing, we focussed on how different 3D printing technologies, materials (in particular metal 3D printing), and finishes are being used. Not only did we see that plastic is still the most used material, and that more finishes are used in general and that the DLMS technology is on the rise, we also saw an interesting development in the use of metal for 3D printing.

Metal 3D printing significantly increased from 28% in last year’s edition to 36% this year. This material is ideal for getting the most out of 3D printing benefits such as producing regular items with less weight. This was the case for when it was used for creating 3D printed airplane seats. These seats were metal printed 50% lighter than regular seats decreasing from 1672 grams to only 766 grams. And as we wrote in ‘’#1 Increase in expertise’’, 3D printing users have become more adapted to 3D printing over the past year meaning that businesses need to experiment more with new 3D printing applications in order to stick apart from all these experts. Metal printing is truly an ideal manufacturing method to experiment with.

#3 Increase in 3D printer purchases

According to this year’s results, we see that more people are owning a 3D printer in general. 66% own one of which 44% own even more than one! If we look at the reason why more people are starting to own a 3D printer, we can see that people wish to use 3D printing for more applications. If we look at the development of purchasing a 3D printer in the near future, we find that buying a 3D printer has become more and more of a long-term priority with 17% saying they will purchase one compared to only 10% last year. If companies wish to experiment more with different 3D printing techniques in order to truly see the benefits this technology brings to their product lines, multiple 3D printers are needed.

#4 Increase in project manager profile hiring

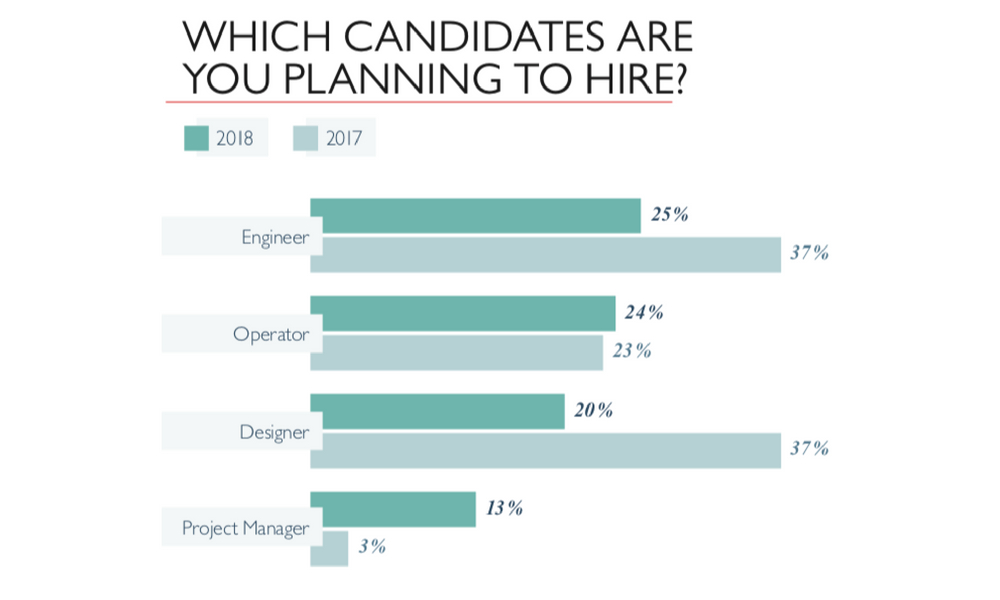

Profile hiring is a very important segment for our State of 3D Printing series as well. We wrote about it in our third part of this series. The most major development we saw was the increasing wish for businesses to hire project managers when compared to the decreased hiring of engineers – 25% wanted to hire engineers this year compared to 37% last year, and designers, with 20% wanting to hire them this year compared to 37% last year. If we look at the actual hiring of project managers, we find that this year, 23% of our respondents are planning to hire projects managers compared to a meager 3% last year. If we would put this side to side with our findings on the increasing level of expertise in ‘’#1 Increase in expertise’’, it can be said that 3D printing related projects are getting more intricate due to the execution being done by an expert. More project managers are needed to oversee these 3D printing projects so that its executed properly.

#5 Medical 3D printing and bioprinting

As we said in ‘’#1 Increase in expertise’’, 3D printing users have become so much more skillful with 3D printing over the past year that businesses need to experiment more with new 3D printing applications in order to stand out from the sea of experts. Medical 3D printing and bioprinting are two new forms of 3D printing. We wrote extensively on medical 3D printing on our blogs such as with topics on 3D printed kidneys and 3D printed hearts. Bioprinting is the process of 3D printing cells or other biomaterials that could be the future of finding new cures for diseases. Such a big development happened with the creation of a new bioprinter, which we wrote about here. Businesses such as 3D printing labs or businesses related to the medical field will find that they will be ahead of the game once they are better knowledged on these topics.

#6 3D printing for mass manufacturing

We asked our respondents what their top priorities are when it comes to 3D printing. The basics such as accelerating product development (39%) and production flexibility (19%) are one of the top priorities but more interestingly, being able to offer customized products and limited series was a very important factor as well with 25% saying so compared to only 16% last year.

In the future, the top priority will be even more emphasized offering customized products and limited series with 26% expecting so. With more people and businesses owning 3D printers, having more experts in this field and with many new ways of being able to apply 3D printing, being able to offer a special product to your customer is key. 3D printing offers the ability to offer mass manufactured products without the major costs that come along with traditional manufacturing methods. Read about this process, and find good examples of mass manufactured and 3D printed products in this blog post.

Need info on other trends?

The above-mentioned trends will have a major impact on the 3D printing industry. But, perhaps you’re interested in specific trends related to certain fields such as the consumer goods industry, industrial goods industry or maybe the aeronautics industry? Find out what developments are to these aspects in our State of 3D Printing 2018, downloadable for free here. If you prefer to read more on the latest technological developments or on new forms of applications regarding the additive manufacturing industry, subscribe to our newsletter to receive the latest news twice a week!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook