The best 5 Tips for 3D printing with Nylon PA12

Posted By Kat Plewa on May 10, 2019 | 0 comments

From electronics to pharmacies and food industry, Nylon PA12 offers a wide range of applications. It is also very well known in Additive Manufacturing for its strength, great mechanical properties, and durability. Nylon PA12 is very popular and produces high-quality parts, but they have to be designed properly. Wondering how to design 3D models for Nylon PA12? Become an expert with our blog post!

How are your parts produced?

Nylon PA12 is plastic, in Additive Manufacturing used as a fine powder. A thin layer of the powder is spread on a printing bed and then a laser fuses it locally in the shape of your parts. This technology is called Selective Laser Sintering. We recently talked about how industrial 3D printing works, you can learn more about plastic, metal and resin printing here.

5 pro tips for 3D printing with Nylon PA12

//www.sculpteo.com/blog/2018/10/03/how-using-3d-printing-for-architecture-projects-can-truly-help-your-business/

Nylon PA12 produces strong parts, but can also be somewhat flexible when it comes to thin objects. It is even suitable for projects that involve food. This 3D printing material is great for mechanical parts, from prototypes to fully functional end products, and also educational models.

There are several aspects to consider when starting your production with Nylon PA12. We will cover Minimum tolerances, accuracy, layer thickness, finishes and also talk about why is Nylon PA12 so popular and what makes it a special 3D printing material.

#1 Geometry of your 3D model

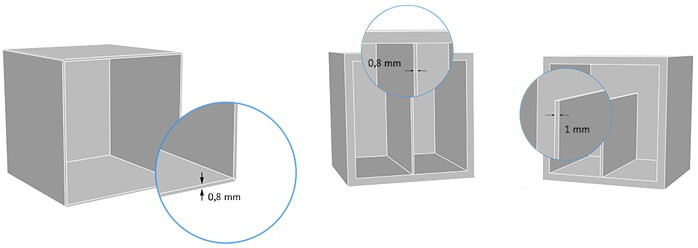

Certain factors have to be respected in order to get the best 3D printing results. If you don’t consider minimum values for wall thickness, clearance, and details, your 3D model will not be 3D printed properly and won’t perform its mechanical properties well. Those restrictions are a result of the 3D printer’s limitations.

| Minimum wall thickness (flexible) | 0.8 mm |

| Minimum wall thickness (rigid) | 2 mm |

| Minimum size of details | 0.3 mm |

| Minimum clearance | 0.5 mm |

| Accuracy | ± 0.3% (minimum of ± 0.3 mm) |

#2 The freedom of PA12

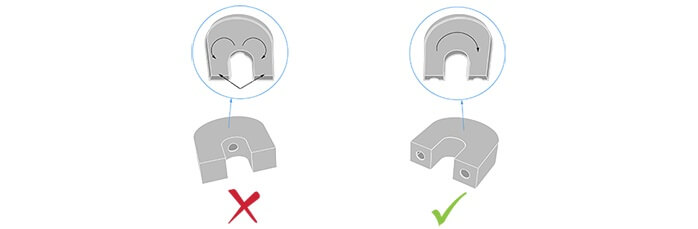

Despite some limitations mentioned above, Nylon PA12 still gives you amazing design freedom. Why? Because it enables design solutions which are impossible to achieve with traditional manufacturing methods.

Let’s start with enclosed and interlocking parts. Can you imagine trying to cast enclosed objects? You just can’t. Additive Manufacturing gives you such a possibility. You can 3D print very complex designs such as chains without any supports.

Producing interlocking parts is also possible. This aspect of 3D printing allows for eliminating time-consuming tooling and speeds up assembly and production time. It also gives you absolutely new design solutions to meet your design requirements.

You can also benefit from the assembly. You have to keep in mind the 0.5 mm clearance between the parts, but it is still an important option to remember when it comes to designing multiple parts.

Last, but not least, your parts can even be hollowed. It is economical because you can remove the material which lets you save money on production. This is also essential for lightweight parts. No other technology allows for manufacturing lightweight, but strong structures like 3D printing does.

#3 Layer thickness

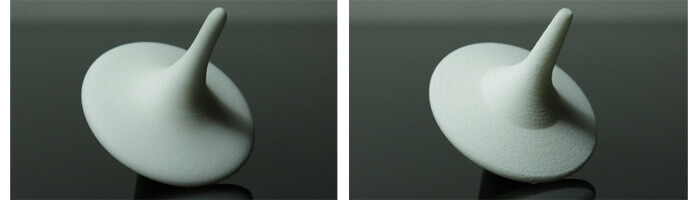

The picture shows on the left-hand side an object printed in resolution 60 µm, and on right-hand side resolution of 100- 150 µm

Nylon PA12 is capable of producing very high-quality projects. It is offered in two resolutions, at a standard layer thickness of 100-150 µm and high definition of 60 µm, where 100 µm is 0.1 mm (0.0039 in). To compare, the average hair thickness is 160 µm. This offers a really amazing quality of your prints.

#4 Finishes

Nylon PA12 offers the largest choice when it comes to colors and finishing options. Most economical is a raw state. The parts are sandblasted to remove excess powder, but the surface is slightly rough. It is possible to polish parts though mechanical polishing to make the parts smoother. Another surface adjustment is smoothing beautifier which gives a shiny appearance and makes parts waterproof. It comes in black and white versions.

You can also get your parts dyed or painted in 16 different colors! Which colors are available and what is the difference between coloring techniques?

Dyed parts are submerged into a color bath and the dye sinks into the walls of the object. With this method, two finishes are available: regular and polished.

Color Resist is a technique of dyeing the models with a matte look and more friction resistant. This method offers a more consistent color between different production batches.

The best upgrade for an object which will be exposed to everyday handling is Color Touch. It gives the parts satin look but also improves it to be more resistant to scratching, rubbing and other external conditions.

#5 Maximum size

Depending on the finish you choose, the maximum size of objects varies. It is important you keep that in mind when you design your parts. If you decide to leave your parts raw, the printers are capable of producing some impressive objects of size 675 x 366 x 545 mm (26.5 x 14.4 x 21.4 in) in one piece with Nylon PA12. For objects much larger or to reduce the printing cost, you can design your object in separate pieces and assemble it afterwards.

Should you use Nylon PA12?

If your project requires either strong or slightly flexible parts, Nylon will meet your needs. It is also a great option when it comes to enhancing your designs with colors and different surface appearance.

How can you start using Nylon PA12 to your benefit? It is easy, just use an online 3D printing service. All you have to do is upload your 3D file and you will get an instant quote! If you’re still unsure or have any doubts if Nylon PA12 is the right choice for you, you can ask any questions you have to our 3D printing experts.

Stay updated with the latest 3D printing News: subscribe to our Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook