Materials used in 3D printing

Posted By Lucie Gaget on Aug 28, 2019 | 0 comments

You may not know all that 3D printing can do for you. More and more amazing 3D printing materials are developed each year to help you give life to all your best projects. Cheaper, stronger, lighter, more resistant to heat, new materials also means new properties. Your 3D printing material choice will depend on your project. In this blog post, we will give you an overview of the existing materials used in 3D printing.

Choosing the right 3D printing material

Choosing the right 3D printing materials is an important step. The types of 3D printing material you choose will determine the shape, the strength and the look of your 3D printed project. Does your project have to be temperature resistant, flexible, food safe or biocompatible? Do you need a strong plastic material or a light metal material?

From consumer products to mechanical parts, additive manufacturing is offering a lot of materials with outstanding properties to create all kinds of projects, from hobbyist 3D printing to industrial 3D printing.

Plastic materials

From Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM), a lot of 3D printing technologies are using plastic materials. It is the most affordable material you will find on the market.

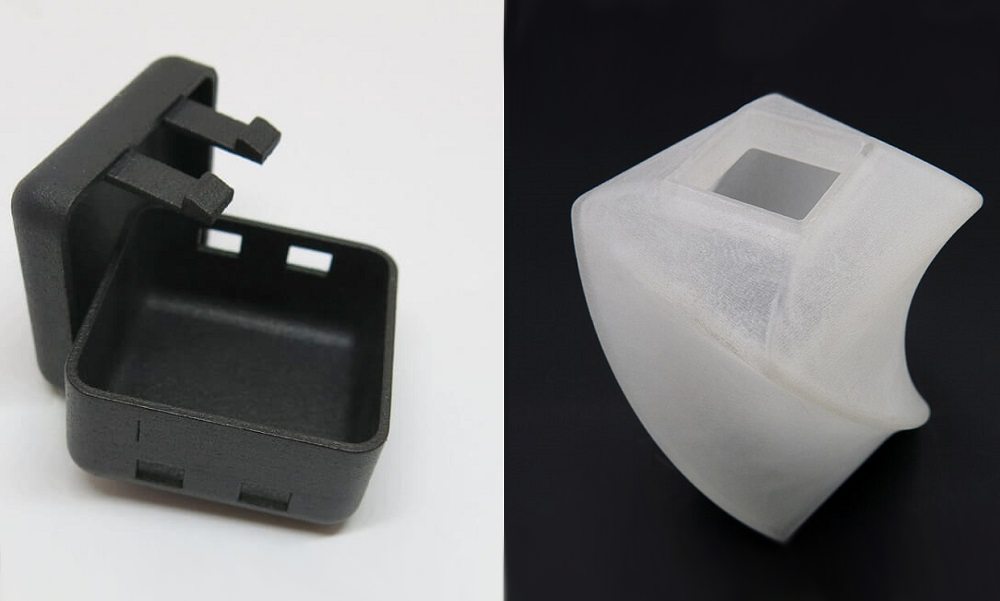

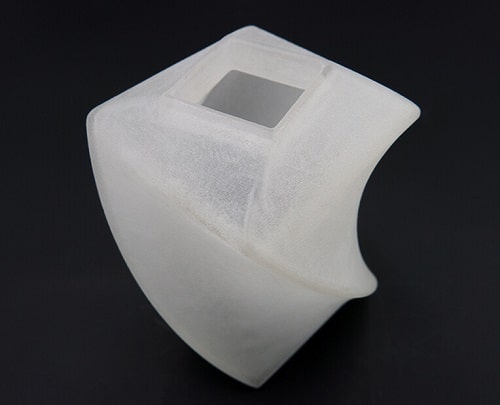

Nylon PA12

Nylon PA12 is a 3D printing material made out polyamide powder and printed using Selective Laser Sintering (SLS), a powder bed fusion technology, to create your 3D models. This material is both solid and flexible, it depends on the wall thickness of your part.

This plastic is particularly suited for rapid prototyping, as the printing process is cheaper and faster. Moreover, a lot of surface finishes and wide-range of colors can be added to your Nylon PA12.

HP Multi Jet Fusion PA12

HP Multi Jet Fusion PA12 is an HP material, also created from fine plastic powder.

The material is characterized by good elasticity and high impact resistance. Moreover, polyamide has excellent resistance to chemicals, especially hydrocarbons, aldehydes, ketones, mineral bases and salts, alcohols, fuels, detergents, oils, and fats. This HP plastic is great for both experienced professionals and beginning designers because of its high precision. Like a lot of 3D printing materials, MJF is water-resistant but not waterproof.

This material, in its raw version, is the cheaper option offered by Sculpteo’s online 3D printing service. Give it a try.

Alumide

Alumide material is a mix of polyamide and fine aluminum particles. This 3D printing plastic material is printed using Selective Laser Sintering process. This plastic is good if you need to prototype a project with a metallic-looking surface. It also has great heat resistance and is strong.

Carbonmide

Carbonmide is a 3D printing material made of plastic polyamide powder and reinforced with carbon fibers. The material is characterized by an excellent stiffness and a maximized weight-strength-ratio. The material is great for experienced professionals and people in need of a strong and lightweight material, and a very high 3D printing precision.

PEBA

PEBA (or Polyether Block Amide) is another plastic material 3D printed using SLS printing process. This material is particularly interesting has it is a rubber-like material, resistant to stress and fatigue.

This material will enable you to create fully-functional models and flexible plastic parts, you could use this material for a lot of different applications from insoles, to medical models, for example.

ABS

ABS or Acrylonitrile Butadiene Styrene is part of the thermoplastic family, coming in the form of a long filament. As its name implies, ABS is created from Acrylonitrile, Butadiene and Styrene polymers.

This plastic 3D printing material is printed using Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). This plastic material is quite popular as it has some great plastic properties, such as a really good stiffness and tensile strength.

PLA

PLA plastic or Polylactic Acid is a vegetable-based plastic material, which commonly uses cornstarch as a raw material. It is the primary natural raw material used in 3D printing.

PLA is a fully biodegradable thermoplastic polymer, which is the most eco-friendly option if you are using FDM technology and need to use 3D printing filaments for your 3D printers.

Multicolor Plastic

Composite multicolor prints objects… already colored. This 3D printing material is using Colorjet technology, which is using a fine powdered material that resembles sandstone. The sandstone material is painted and adhered during the printing process. As the material is painted during the process, the file must also contain texture information.

Composite Multicolor prints are thus the most rapid and economical way to arrive at a full-colored object.

Resin materials

A lot of resin materials options are also available. Even if this option is not as cheap as plastic, it can offer you great mechanical properties.

VeroWhite resin

The VeroWhite resin creates 3D printed objects from a base of photosensitive polymer liquid. Then, that liquid is solidified by UV light layer by layer to create rigid and highly detailed 3D prints which are comparable to injection molded plastics. This is a process called photopolymerization.

The final product made with the VeroWhite resin has a naturally smooth surface.

VeroClear resin

This VeroClear resin is a smooth translucent material. Just like the VeroWhite resin, the 3D printed objects are made using a base of photosensitive polymer liquid, solidified by UV light.

Polyjet resins are particularly precise and allowing to create incredibly detailed 3D printed parts.

Elastomeric Polyurethane

Elastomeric Polyurethane, also known as EPU, is a high-performance polyurethane elastomer. This resin material offers excellent elastic behavior under cyclic tensile and compressive loads.

Elastomeric Polyurethane is 3D printed through DLS process, (for Digital Light Synthesis) or CLIP process (for Continuous Liquid Interface Production). DLS works by projecting a continuous sequence of UV images, generated by a digital light projector, through an oxygen-permeable, UV-transparent window below a liquid resin bath. The dead zone created above the window maintains a liquid interface below the part. Above the dead zone, the curing part is drawn out of the resin bath.

Flexible Polyurethane

Flexible Polyurethane, also called FPU, is a semi-rigid material with good resistance to impact, abrasion and fatigue. This versatile resin material was designed for applications that require the toughness to withstand repetitive stresses such as hinging mechanisms and friction fits.

It is a good flexible material, but not as flexible as PEBA, the rubber-like plastic we told you about before.

Rigid Polyurethane 70

This Rigid Polyurethane resin, or RPU, is the stiffest and most versatile polyurethane-based resin we are offering on Sculpteo’s online 3D printing service. It performs well under stress, combining strength, stiffness, and toughness.

These properties make RPU particularly useful for consumer electronics, automotive, and industrial components where excellent mechanical properties are needed.

Urethane Methacrylate

Here is another resin using the CLIP process: the Urethane Methacrylate resin, or UMA 90.

Parts printed with the CLIP technology are much more like injection molding objects. The absence of post-production treatment shortens the production time and lowers the costs of production, which makes UMA perfect for fast and efficient prototyping, manufacturing tooling and fixtures.

Metal materials

The use of metal 3D printing is growing in a lot of different sectors such as aerospace and aeronautics. If you are interested by this technology don’t forget to download our ultimate metal 3D printing guide for free. Now let’s see which materials are available for metal 3D printing, and how our metal 3D printers can help you.

Aluminum

At Sculpteo we are offering Aluminum AlSi7Mg0.6, a fine metal powder composed mainly of aluminum (90%), silicon (7%) and magnesium (0.6%). This material is offering good mechanical properties and can be used for parts subject to high voltages. This metal alloy is printed with the Selective Laser Melting (SLM) technology. This aluminum is commonly used in foundries for fine objects and complex geometries, using this material, you will be able to create precise projects. The second advantage of aluminum AlSi7Mg0.6 is its very low weight for a metal material. These properties make aluminum AISi7Mg0.6 effective in areas where a strength/mass ratio, as well as good thermal properties, are required.

Titanium

Objects printed with Titanium 6AI-4V at Sculpteo are created from a fine metal powder composed mainly of Titanium (88-90%), Aluminum (5.50-6.5%) and Vanadium (3.50-4.50%). This titanium-based alloy is perfect for your parts, if you need parts resistant to acid and oxidation.

Stainless Steel

Stainless Steel can be printed using different metal 3D printing processes: Our online 3D printing service is using this material with both Direct Metal Laser Sintering and Binder Jetting. This material is good to print small parts, resistant against corrosion and high temperatures. Stainless Steel is commonly used to create parts for the consumer goods sector.

What about silver, or brass?

Using Casting, you will be able to get silver, bronze or brass objects. Lost-wax casting is an alternative to additive and subtractive manufacturing to manufacture your parts with precious metals. The master model typically built in wax thanks to 3D printing is the perfect replica of the finished product. Once the master model is created, a mould made in plaster is poured over it. Once the plaster mold is ready, liquid metal in injected into the mold to replace wax which is drain away through a treelike structure to create the object.

New innovative 3D printing materials

New materials are released quite often, allowing to create brand new projects, find new advantages and make the most of new material properties. If you read our blog, you certainly already know about the new revolution of 3D printed wood filament, the strongest material, graphene, but also the game-changing material for construction: 3D printed concrete.

We hope that this 3D printing materials guide helped you to choose your future material. If you are still not sure about which material you should use for your 3D printing project, feel free to contact our sales team.

If you already have your 3D file ready, you can upload it on our online professional 3D printing service and get your instant quote

Subscribe to our newsletter to get all information about the 3D printing industry.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook