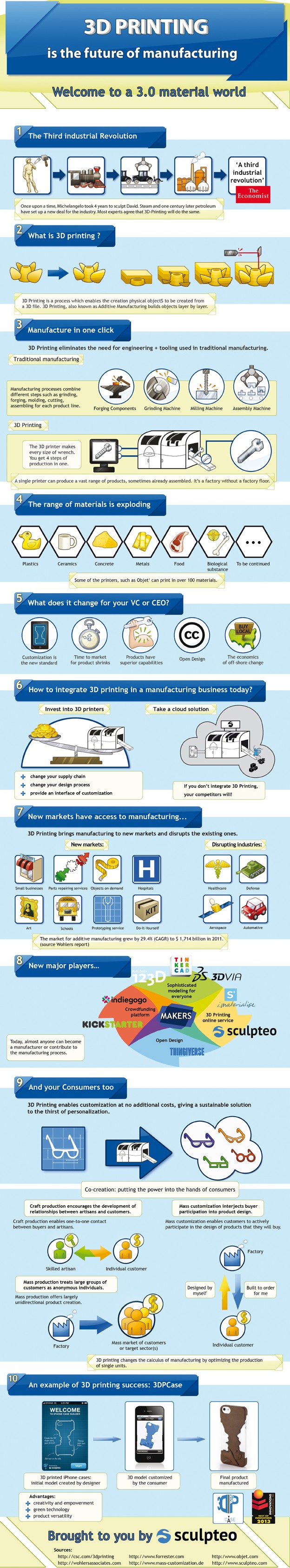

3D printing Infographic: the Future of Manufacturing

Posted By Sculpteo on Dec 27, 2012 | 1 comment

Last update: 02/21/2017

Discover our 3D printing infographic about the future of manufacturing. It’s time to find your way in a 3.0 material world!

Infographic and sources

In this 3D printing infographic, you’ll get the basic definitions of 3D printing. You’ll learn how it works, how 3D printing is different from and can be complementary to traditional manufacturing and the range of 3D printing materials that are available today. What’s more, we give you keys to integrating 3D printing into your own business, comparing it to your own industry and other ones.

3D Printing technologies

Additive manufacturing is more than ever widening and exploring new possibilities. At Sculpteo, we offer various 3D Printing Technologies to give you the opportunity to accomplish your projects.

– Selective Laser Sintering (SLS) is a 3D printing polyamide power-based process. The powder is transferred thanks to a recoating tool onto the build stage in the process chamber. Then, a laser scans the thin layers of powder, layer after layer. SLS doesn’t require any support structures which makes it possible to 3D print very complex shapes and integrated design.

– Stereolithography (SLA) is a liquid-resin-based 3D printing. It is the first 3D printing process invented, in the 80’s! The liquid is exposed to light where the UV laser draws a cross section layer by layer.

– CLIP technology was invented by Carbon American company. They produce their own resins, which have very powerful mechanical properties.

– Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are for metal 3D printing.

There are other 3D Printing Technologies such as FDM, DLP, …

3D printing is the future of manufacturing

Ready to be part of the new 3D printing world?

Learn more!

Have a look at our glossary, where you can find all you need to know on 3D printing.

In our “Benefits of 3D Printing” series, you can find much info on:

– Impossible Designs and Internal Channels

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook