Metal 3D Printing: A Game-Changing Technology

Posted By Hilmiyati Kusnadi on Jun 14, 2017 | 0 comments

Metal 3D printing becomes more and more essential for manufacturing since it allows to produce fully functioning parts with high mechanical properties and also geometries that would be impossible to produce with traditional manufacturing techniques. According to our annual report, The State of 3D Printing, metal ranks the third of the most used additive manufacturing materials. That is why today you will discover more about what are the key trends in metal 3D printing.

The data we collected to find the key trends of metal 3D printing comes from Business Case, one of the tools of our Agile Manufacturing Technology (AMT) software suite.

What is Business Case?

Business Case is a new software dedicated to 3D printing, allowing you to audit and evaluate your project. This is the first 3D printing software designed as a self-learning Artificial Intelligence engine. It helps you to check whether a CAD file is optimized for additive manufacturing by providing advice about which materials are most appropriate and helps you optimize cost and time needed for your 3D printing project.

If you want to know more about Business Case, you can read this article: Agile Manufacturing Business Case: The First AI for your Metal 3D Printing Projects. Or you can visit this dedicated page for Business Case.

A special focus on metal 3D printing

Each day, more than 2,000 users are using our AI engine Business Case to check the feasibility of their projects. Since Business Case offers an extensive audit for Metal 3D Printing, we took this opportunity to collect data and insights.

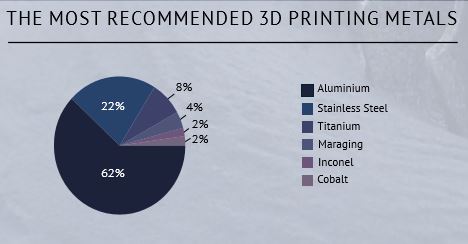

1. Aluminum is the most recommended metal material for 3D printing

Concerning the metal materials, aluminum is the most recommended (62%), followed by stainless steel (22%) and titanium (8%).

2. Metal 3D Printing is used to 3D print small quantity of objects

In terms of quantity of objects being manufactured, almost half of the users only 3D print one object (46%), and 23% want to 3D print between 2 to 9 objects. Moreover, 12% of our respondents require pieces that are different one from another.

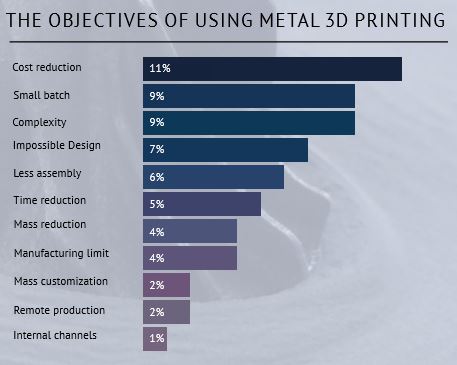

3. Cost reduction is the main objective of adopting metal 3D Printing

Indeed, cost reduction ranks first with 11% as the objective of using metal 3D Printing followed by the complexity of the design with 9%. Other 9% goes for the production of small batch, this point being related to the previous key trend regarding the quantity of objects. One possible reason that the respondents chose small batch production can be that it allows to test a product on a small number of clients before modifying the next batch according to the results.

What is new in metal 3D Printing in 2017?

Through Business Case, we prove that metal 3D printing is evolving. The latest news in metal 3D printing is the Stainless Steel 42 SS/BR using Binder Jetting technology.

This Binder Jetting Stainless Steel material is made from a fine stainless steel 420 powder. The material is composed of 60% of stainless steel and 40% of bronze. During the 3D printing process, the material is infiltrated with bronze to add resistance and strength to the object.

Using the Binder Jetting technology, this additive manufacturing method creates parts with a binding agent. During the printing process, the liquid binding agent is deposited on the metal powder material, layer by layer, until it forms an object. When each layer is deposited, the powder is slightly cured for solidification. You can refer to our technology page to learn more about the Binder Jetting process.

Binder Jetting Stainless Steel can be used for engineering components and small technical parts if the design and technical specifications are respected. Thanks to the plating option, this material is perfect for 3D print jewelry, as well as decorative and ornamental objects.

Discover more about our new material in this dedicated material page.

Beside Binder Jetting Stainless Steel, we also provide metal 3D printing with more materials and technologies.

- Aluminum AISi7Mg0,6 using SLM technology

- Titanium Ti64 and Stainless Steel 316L using DMLS technology

- Sterling Silver and Brass material using Metal Casting

The 3D printing industry becomes more stable and professional. To find what are the other trends in the 3D printing industry, simply download the State of 3D Printing 2017.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook