3D printed watch: The most promising projects

Posted By Lucie Gaget on Dec 19, 2017 | 0 comments

Are horological structures 3D printable? Indeed, additive manufacturing can develop interesting and complex objects such as 3D printed watches, which you can already find on the market. But even if 3D printing leads to innovation in various sectors, there are still some challenges to face. Entirely 3D printed watches are still one of them because of their complex mechanism. 3D printing is also expanding the boundaries of traditional watchmaking. These high-quality creations can be offered to timepiece collectors, but they would please anyone else with their elegance.

Some brands and clockmakers are actually working on 3D printed watches, we are going to see in this blogpost all the challenges of building a 3D printed watch. But we’ll also show you all the real advantages of 3D printing to make a watch, through the example of two amazing brands: ALB Watches and Holthinrichs Watches.

Watches: how 3D printing can be an asset

For a clockmaker, the main advantage of using 3D printing for his watches is simply freedom. Indeed, this manufacturing process offers a lot of freedom during the creative process, but also during the production. If it can be used for rapid prototyping, it is also an adequate solution for production. Let’s see how it is possible to make the most of the 3D printing technology to create impressive 3D printed watches.

3D printing, a technology allowing to create complex and accurate objects

The additive manufacturing technology allows to create more and more different items, even some complex mechanisms. For example, 3D printing allows to create 3D printing sculpture for space, 3D printed drones, 3D printed medical devices to save lives, and so on. At Sculpteo, we see everyday the new possibilities offered by this impressive cutting-edge technology. Some projects are still more difficult to make, and for example, entirely 3D printed watches are still complex to be made with additive manufacturing. However, it doesn’t mean that it is totally impossible.

Indeed, 3D printing allows more freedom in the design, it offers the opportunities to create new shapes. Simple shapes, complex shapes, everything is possible. Designers can work on the design to really make what they want, and not only what it is possible to make.

It is not that hazardous if 3D printing is more and more used in the fashion industry or to create jewelry. Impressive designs can be created just in one part.

An advantageous production process

Vincent Candellé Tuheille and Simon-Pierre Delord are the two founders of ALB watches. They chose to 3D print their watches is because it was the only way to achieve the result they wanted. Without additive manufacturing, this project couldn’t have seen the light of the day. Indeed, 3D printing is a cost-effective method to create only a few watches, for different models, avoiding to use a mass manufacturing process. You can print small batches, which is a real advantage for projects like this one.

You also have the possibility to redo your model and reprint a new version while prototyping, which is impossible with manufacturing methods such as injection molding. Using 3D printing gives the opportunity to work with a faster manufacturing process, and develop your product quite quickly.

3D printing materials and techniques adapted to your needs

3D printing allows you to choose among different materials and techniques. If some clockmakers are choosing to work with plastic like ALB, some other, are preferring metal, like Holthinrichs.

It totally depends of the final characteristics and look that you want your 3D printed watch to have. For example, Selective Laser Sintering is the perfect method to 3D print the plastic of the ALB watches and give them this artistic look. On the other hand, Binder Jetting is the most adapted technique to give Holthinrichs watches their vintage look.

We’ll see later in this blogpost the techniques tested to 3D print the whole mechanism of a 3D printed watch.

Customized watches

This manufacturing process allows to create on-demand designs and objects and can obviously interest watchmakers. Customization is also one of the the main advantages exploited by ALB Watches and Holthinrichs Watches with 3D printing.

Indeed, 3D printing allows mass customization: it is actually the perfect solution to get customized items at a lower price. Thanks to this possibility, ALB Watches developed four different watches models.

Customization is also an option offered by Michiel Holthinrichs, it is possible to order a watch with a personal message on it. The case of the watch is 3D printed, and using high-ends 3D printers offers the possibility to customize the objects with personal texts.

They make the most of 3D printing!

ALB watches

ALB, “Atelier le Brézéguet”, is one of our customers, at Sculpteo. This is a french brand from Toulouse, founded by Vincent Candellé Tuheille and Simon-Pierre Delord. This company is specialized in watches, and more precisely, in wearable 3D printed watches. These parts are a mix of craftsmanship and modern technologies. ALB watches are automatic watches, which means that a mainspring is powering the movement thanks to its energy. They are all using the ETA 2671 movement to work and their functioning time is about 38 hours.

What are the 3D printed parts on these watches? The black rings, on the top and the bottom of the watch, are printed with polyamide. Moreover, these parts are created with our online 3D printing service. These watches are quite luxurious, with 25 rubies on each model. They all have elegant 3D designs, elaborated by the two passionate founders of the brand.

You can find four different models on their website, with four different styles and themes: the ALB 000 “Balade au Brézéguet”, the ALB 100 “Secondes d’Eclipse”, the ALB 200 “Promenade à Etretat” and the ALB 110 “Vers le bout du monde”.

Don’t hesitate to check their website if you’re interested in buying a 3D printed watch.

Holthinrichs Ornament

Holthinrichs watches was founded by Michiel Holthinrichs, who was originally an architect. This brand from Delft, in the Netherlands, claims to be the pioneer in 3D printed watches. The watch Ornament 1 is a 3D printed watch, the case, the crown and the buckle are 3D printed in stainless steel 316L.

These watches have a classic design, but are made with modern technologies. Even if these watches are looking very traditional, if you look closely to the design, you will see some complex shapes. 3D printing is a great help to design this kind of details.

The products of this brand are a mix of engineering and craftsmanship. It also shows how metal 3D printing helps to create these kind of projects. Indeed, this 3D printing technology is really useful for jewelry creations.

3D printing the mechanism of a watch: The biggest challenge

Building a watch is a difficult process, it has to be very accurate and there is no space for approximation. The tourbillon is a particularly complex mechanism, but it is essential for a watch to give time. Thanks to the escapement and balance wheel, the mechanism goes against the effect of gravity. This assembly is then continuously rotating at a slow rate. All of this process has to be very precise so the watch can give the right time.

As we saw in the previous examples, 3D printing is mainly used to create the ornaments, the case or details of the watches. It not possible yet to entirely 3D print a small and wearable watch, with a whole 3D printed gear. Why is it such an impossible challenge for the moment?

3D printing materials are not the problem. Indeed, it is possible to print with Fused Deposition Modeling machines, but also with Selective Laser Sintering or Binder Jetting techniques to get a professional finish. Even for the mechanical parts, each technology has its strengths and weaknesses and could fit. The lightness of the HP Multi Jet Fusion PA12, or the resistance of Carbonmide, could be very useful. Actually, every material could potentially be used, the problem is not there.

Here is the main issue: the 3D printing technology is very accurate, but does not allow to print something as little as a watch’s gear. Indeed, these components are too small for the present technologies that we know. However, the 3D printing technology offers enough materials to make prototypes and great partially printed products, like ALB and Holthinrichs watches. You only have to wait for the 3D printer that will be able to work precisely on thousandth of millimetre. For the moment, no laser is able to work on a surface which is this small.

However, some clockmakers tried to 3D print the mechanism of a watch using plastic like PETG (Polyethylene terephthalate) and PLA (Polylactic Acid). These watches are created in a way bigger scale. You will see that with a bit of ingenuity, they succeeded. It will certainly be possible in the future of 3D printing to create these same mechanisms using only very small parts to make real 3D printed watches. Here are some examples of 3D printed tourbillon in plastic.

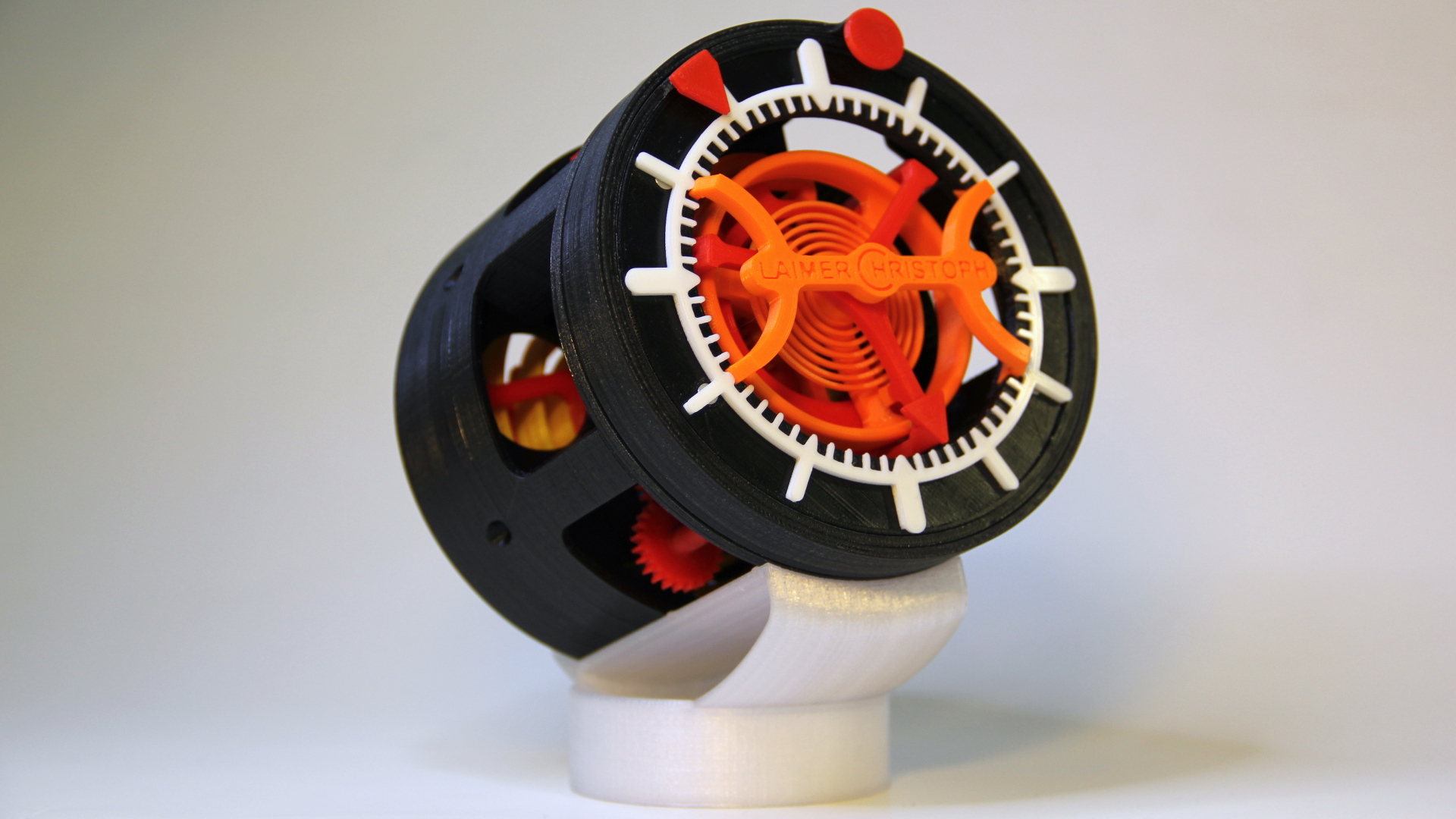

Christoph Laimer and his 3D printed tourbillon

This watch may seduce you with its atypical design, and mostly with its ingenuity. Christoph Laimer, a 3D design passionate, creates amazing 3D printed timepieces. After a first mechanical clock project in 2013, he decided to go further in 2016 with the Laimer Tourbillon.

With this last creation, he decided to build a tourbillon that is made out of 3D printed plastic. This projects required a lot of engineering efforts to achieve such a result. Indeed, this watch has a 3D printed mainspring. Plastic is not flexible enough to create a traditional mainspring, it would progressively lost its initial form and properties. That is why all the mechanism had to be reinvented.

The 3D printing materials used for this 3D printed watch were two different types of plastic: PETG (Polyethylene terephthalate) and PLA (Polylactic Acid). Christoph Laimer used a desktop 3D printer to make its amazing 3D printed timepiece. The case was printed in PETG, and the internal mechanisms were printed in PLA.

This watch runs for 30 minutes and then needs to be rewound. For the moment, it can’t last longer, but as passionates clockmakers are always developing new projects and making the most of additive manufacturing, these watches could be able to last longer soon.

The Laimer Tourbillon is an impressive and meticulous work. It required more than 50 3D printed parts to be able to work. Watch the video below to get a better understanding of the whole mechanism and assembly process:

Tourbillon 1000%, the modern clockmaking

The Tourbillon 1000% is designed and printed by Nicholas Manousos, who chose to develop this amazing project in New-York, during 3 years. This functioning timepiece is printed 10 times bigger than a traditional tourbillon. The only components that are not 3D printed are the ball bearings of the watch.

source: Hodinkee

This Tourbillon 1000% is quite an impressive clock, entirely 3D printed in PLA (Polylactic Acid), a biodegradable plastic. A desktop 3D printer has been used to create this project. Like for the Laimer Tourbillon, the mechanism has been reinvented to work with accuracy.

Even if the size of this watch is not really convenient, because you can’t wear it normally, it is a perfect educational project. Indeed, the size of the clock allows to see perfectly all the mechanism. It is manipulable and even more practical with this size. 23 printed parts are assembled in this project to create the Tourbillon 1000%.

To see the mechanism of this Tourbillon 1000% in action, watch the video below:

Jewelry, fashion and luxury industry: 3D printing is everywhere

It’s not that surprising to see 3D printing making its first steps in clockmaking. This technology is already used in fashion to create accessories, like 3D printed shoes, and even jewelry. It allows to create complex shapes, to work with various printing materials and to make on demand items, in small batches. It’s a good way to make atypical products, but also to customize them.

Metal 3D printing, as we saw with Holthinrichs Watches, is a good ally to 3D print jewelry, and tends to be more and more common.

This technology is more and more used by big brands as well as little companies, not only for rapid prototyping, but to create end-use products. Additive manufacturing is accessible to everybody, thanks to our online 3D printing service. If you are planning to create your own clock or jewelry part, check out our top of the best 3D modeling software for jewelry.

We hope that you learned a lot of things about 3D printed watches. You want to 3D print your own watch? Upload your models right here. If you have any questions about 3D printed watches, don’t hesitate to contact us.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook