Eliminating 3D printing support material: Our best tips

Posted By Marianna Papageorgiou on Dec 26, 2017 | 0 comments

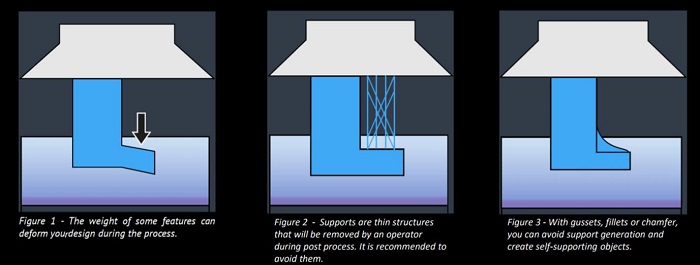

3D printing enables the creation of many complex models and impossible designs. Yet, there are some limiting factors that complicate the 3D printing procedure. The use of 3D printing support material is one of them. Even if it is an essential parameter that leads to a successful 3D printing result, it is often an obstacle that may lead to part deformation, or leave marks on the 3D printed surface. Thanks to our tips though, you can improve your skills when you make a design for 3D printing and you will avoid these unwanted results in your surface finish. From 3D printer dissolvable support management to the total elimination of 3D printer support material, here are our special tips for a successful 3D print without supports!

What is the 3D printing support material?

In the Additive Manufacturing technology, the object is created by the successive addition of layers, one on top of the other. This means that a layer cannot be deposited if there is no material underneath to support it. Considering that, it is quite difficult to 3D print structures such as bridges, overhangs and holes. In this kind of cases, 3D designers use support material. In other words, support material in 3D printing is the solution to problems against gravity pull!

Support materials are structures that are 3D printed along with the actual 3D model, to provide support to fragile, thin or overhanging areas. In this way, the vulnerable parts of printed objects are strengthened and the whole 3D model is kept in proper shape during printing.

3D Printing support material: How is it generated?

There are various ways to generate the support material.

Some FDM (Fused Deposition Modeling) 3D printers use the same filament to extrude both the support structures and the actual 3D model. Since this kind of support structures has to be trimmed off manually, it cannot be used for providing support to internal structures, otherwise it will be trapped inside the 3D printed object.

The density and the geometry of the support structure is set manually by the 3D designer, when getting started with setting all the parameters for the 3D print.

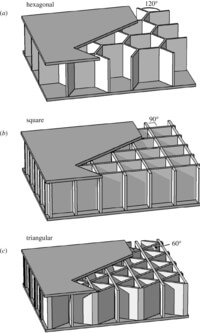

Before setting off the 3D printing process, the designer or the user of the 3D printer has to set the parameters regarding the extrusion of the support structures. It is possible to choose the geometry and the density of the applied structure. The various options include hexagonal, square or triangle structure arrangement. It is also possible to adjust the density of the structure, depending on the volume of support material that needs to be provided. However, it is generally recommended that the structure of the support material is not very dense, as it will be difficult to be removed during post processing.

Support material and 3D printing technologies

Not all technologies are of the same need for 3D support material use. For example, a 3D printing technology that definitely needs support materials is the FDM (Fused Deposition Modeling). As layers are added one on top of the other, nothing unsupported can be printed. On the other hand, the SLS (Selective Laser Sintering) technology does not require any special support material. In SLS printing, the powder that is being sintered during the building process is being used as support material itself.

In addition, as it is extensively explained in our e-book about “How to design for Digital Light Synthesis (CLIP)”, CLIP technology requires special attention when comes to support materials.

Moreover, when designing specifically for metal 3D printing, you have to take into account some design considerations for this technology. Like for example the orientation of the print, the supporting angles, the overhanging surfaces in order to adjust the 3D printing supports accordingly. You can find detailed information about how to design support structures for this specific technology in this guide dedicated to metal 3D printing.

3D printer dissolvable support

Another common way to deal with support structures is to use the dissolvable ones. In this case, the 3D printer extrudes from two different nozzles two different kinds of materials. The main material that is extruded from the first nozzle is meant to build the actual 3D part. The secondary nozzle, extrudes a plastic of different composition than the main one, and is used for creating the support structures. This secondary material, is soluble support material. Once the 3D print is completed, the 3D printed object is submerged into some liquid, usually water. When immersed in the liquid, the chemical reaction between the secondary 3D printed material and the liquid dissolves the support structure, without affecting the 3D printed object.

Generating 3D printer dissolvable support is considered a very convenient solution. The surface finish of the 3D printed object is smooth and it is less probable that the supports leave marks from their contact with the main material. In addition, dissolvable support structures can be applied to support internal structures or complex geometries that could not be created without being supported.

To get more detailed information about dissolvable 3D printed supports, please refer to our previous blogpost about this innovation in metal 3D Printing industry.

Disadvantages of using support material in 3D printing

Regardless using a water soluble material or not, printing a supporting structure is an additional factor that adds time to the construction of the 3D part. The more complex and dense the structure of the support that is being printed, the more time consuming the procedure of 3D printing will be. So, a useful tip would be to keep the structure of the 3D printed supports as simple as possible.

Another disadvantage of the use of support material is that it may lead to dimensional inaccuracies. This is due to the fact that supports affect the quality surface of your 3D printed part. Since during post-processing, the object is submitted to polishing of its surface, a slight alteration to its initial size may occur.

Last but not least, there is always the problem with the remaining marks on the surface. In case that the support material is difficult to remove or it is not cleaned properly, the surface finish of the 3D printed part will not look that flawless as it was supposed to be.

Support material in 3D printing: How can it be avoided?

For all the reasons mentioned above, it is highly recommended that you avoid the use of 3D printer support material when possible. From our experience in 3D printing, we gathered some tips for you that you can follow in order to achieve a better surface aspect.

Choose the best part orientation

Adjusting the orientation of the 3D printing of your part is the easiest way to ensure the least possible use of support material. Depending on the direction of your print (vertical, horizontal or in an angle), you may use less or more support structure. This happens due to the fact that in each direction there is a different surface that is attached to the printing bed so the 3D part is build up in different ways. Thus, the need for support material may vary.

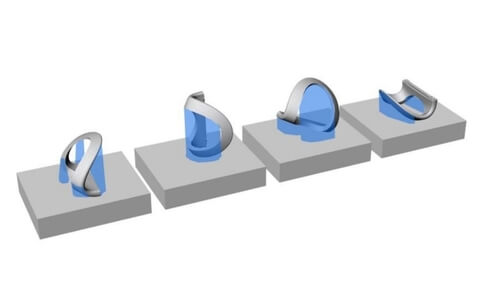

The picture below, visualizes this concept of how you can build materials in different directions. The same part is aligned in 4 different ways and each case generates different need of usage of support material. The blue surface illustrates the support material.

However, keep in mind that if your 3D printed parts need to be assembled, they have to be printed in the same direction, so as they fit each other properly.

Design of specific features to create self-supporting 3D printed parts

The use of fillets, chamfers or gussets can be an alternative solution to the generation of support structures during the manufacturing process. These are some design features that usually support fragile parts with high aspect ratio (long and thin). Moreover, they are often used as modifications to the initial design of the 3D model that create self-supported objects.

We also recommend you to avoid sharp angles and use curved corners instead. The rounded edges generate less internal stresses than the sharp ones, so they can support the weight of the constantly added material on the z axis, without experiencing deformations during printing or afterwards. So, if your design has sharp edges, try to gradually curve them, so that you get a smoother and finer result.

Last but not least, when adding fillets to your models, try to use angles above 40°. Wall angles above 40 degrees are more self-supportive, a case that eliminates the need for support structures and consequently accelerates the printing procedure.

3D printer with moving printing platform

A 3D printer with moving printing bed is another smart, yet more complicated way to eliminate the need for supports in 3D printing. Two students from the Zurich University of Applied Sciences, Oliver Tolar and Denis Herrmann, came up with the idea that 3D printing on an angle can eliminate any overhang angle. To give life to their idea, they created a 3D printer whose print bed is being tilted during the additive manufacturing procedure. By synchronizing the tilting direction of the printing platform with the extrusion speed of the material, they managed to eliminate the need of 3D printer support material for the overhanging areas. However, an industrial 3D printer does not come with a moving printing bed, so this alternative solution is a very special one and cannot be applied in many cases, especially for commercial uses.

The video below illustrates the way this unique 3D printer works:

The use of support material has always been a limiting factor in 3D printing. However, a lot of research is going on for coming up with new ways to avoid its use. Like in the case of these dissolvable 3D printed supports used in metal 3D printing. We hope that soon scientists and researchers will find new alternatives to this problem to make the 3D printing process even easier!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook