3D printed house: How additive manufacturing is helping to build homes

Posted By Lucie Gaget on Feb 14, 2018 | 0 comments

Additive manufacturing is becoming a great asset for the construction industry. It is now possible to build impressive structures with elaborated designs at an architectural scale. Thanks to new XL 3D printers and new printing materials, 3D printed houses are now a reality. Large-scale 3D printing is allowing to build bigger projects like urban features, pedestrian bridges, entire houses, or buildings. In the future, you could even live in your own 3D printed house!

In this blog post, we are going to see how 3D printing is beginning to revolutionize the construction field and more specifically housing construction, thanks to large-scale 3D printers. Then we will show you the most impressive 3D printed house projects or experiments that have been made.

3D printing in the construction industry

3D printing shows its efficiency and benefits everyday different sectors such as the medical industry or the fashion industry. This technology can really be helpful on many levels, from prototyping to production. It is now possible to think about bigger projects with additive manufacturing, as the large scale 3D printing system is now really improved. It is an asset for the construction field, it allows to rethink totally the manufacturing processes.

3D printer manufacturers perfectly understand all the benefits of 3D printing at a bigger scale, that is why we can see that more and more XL printers are appearing on the market! More specifically, we saw this trend booming at Formnext 2017, a trade show focused on additive manufacturing. Indeed, a lot of companies released large scale 3D printers during this event. Read more about these innovations here.

3D printing to create models

This is certainly the best-known part of 3D printing: additive manufacturing is really convenient to create models. In architecture, it can be used to make the first renderings before the construction of a project.

Having a model to get a better insight of the final project is always useful for architecture firms. Indeed, in architecture it is always good to have a model of the future construction for the customers but also to have a great overview of the final project, to see if it works, if it looks like it was supposed to look like. Then you’ll be able to adjust and modify your 3D file before the printing process. With the 3D printing technology, it is possible to make many iterations for just one project, something that is impossible (or really expensive) when using a traditional manufacturing method such as injection molding.

In order to get your printed model, you just have to create your 3D model with a 3D modeling software, and then upload it on our online 3D printing service! If you need some advice to choose your 3D modeling software for construction projects, we made a selection of the best 3D software for architecture.

3D printing directly for construction

If additive manufacturing is good to create models and prototypes at a lower cost, it is also a new way to create houses and other big structures.

3D printing is now a new tool for civil engineers! Indeed, some projects already have been made, it is possible to create 3D printed bridges, or 3D printed urban features and concrete houses. This technology also offers you different possibilities. For example a 3D printed concrete house can be printed in one part directly on spot, or in separate parts and then assembled.

In order to achieve these amazing projects, new technologies and materials are developed. Let’s see how it is possible to get those 3D printed structures.

What are the 3D printing techniques used for construction?

3D printing has a fast technological development. It is now possible to print large parts thanks to the new 3D printing systems that are emerging. Most of the time, the large-scale 3D printers that are used to create houses are machines with automated arms. It wouldn’t be convenient to have a traditional 3D printer to print a full-sized house in just one part. A construction 3D printer has to be capable of printing really big structures. That is why a robotic arm is used to deposit the material, it allows to print big architectural designs directly in one part.

Large-scale 3D printers are actually able to print with different materials. A lot of 3D printing materials are making their entrance on the market. For example, some new sustainable materials are used to print architectural structures. It could be a great way to develop sustainable housing.

Now, even 3D concrete printing is possible. Some concrete 3D printers have been developed, but it is also possible to get a printed structure in metal or plastic for example. If you are interested in concrete 3D printers, you can read our recent blogpost about this new kind of printers here. As metal 3D printing is more and more developed in the 3D printing industry, it is also becoming easier to print large 3D printed metal parts.

Here is an example of a large-scale concrete 3D printer:

credit: https://www.designboom.com/technology/tu-eindhoven-concrete-3d-printer-06-28-2016/

What are the benefits of 3D printing for houses?

You can work on the designs

If you are used to 3D printing, you know that this manufacturing technology is perfect to work on designs. With 3D printing you are free to design anything, any kind of structure.

And now, it is possible to work on architectural designs! Additive manufacturing is giving a lot of freedom when it comes to designs, it is a really good advantage for the architecture sector.

This new building technology offers a wide range of possibilities. You can 3D print a large variety of projects with different designs, not only homes. It could be a great way to build offices, hotels, tiny homes, real villas or to reconstruct homes after a natural disaster.

The advantage of digital manufacturing is that you can modify your model and its design as many times as you want.

You can build it faster

Automated construction has many advantages, and one of them is that it is time saving! A machine can work continuously – we will see later in this blog post that some houses were built in a record time thanks to additive manufacturing. It works faster, and it creates really accurate constructions.

That is especially why this could be a good solution to do quick housing construction after natural disaster. It could be a great way to build quick emergency homes

You can reduce the costs

Building a house can be really expensive. You are maybe wondering how you could reduce the costs of house-building? This new construction technology can help you to reduce them. With a 3D printer, you only use the amount of material that you need for your construction project. It allows to avoid the waste of material.

Moreover, this technique can help you reduce the tooling and labour costs. You only need a machine, and someone to program it.

A new possibility to build houses anywhere

For a construction company, additive manufacturing is a new opportunity. With these new 3D printing systems, it is possible to have a house 3D printed anywhere. Be careful: house 3D printing is taking in account the construction rules of the area, obviously. But it appears to be a great solution to build houses in remote area. There are less tools and machine to transport, but it has to be accessible for a large printer.

Best 3D printed houses

As a lot of experiments have been made regarding 3D printed houses, let’s see what the most impressive projects are!

3D printed homes for 4,000$ only?

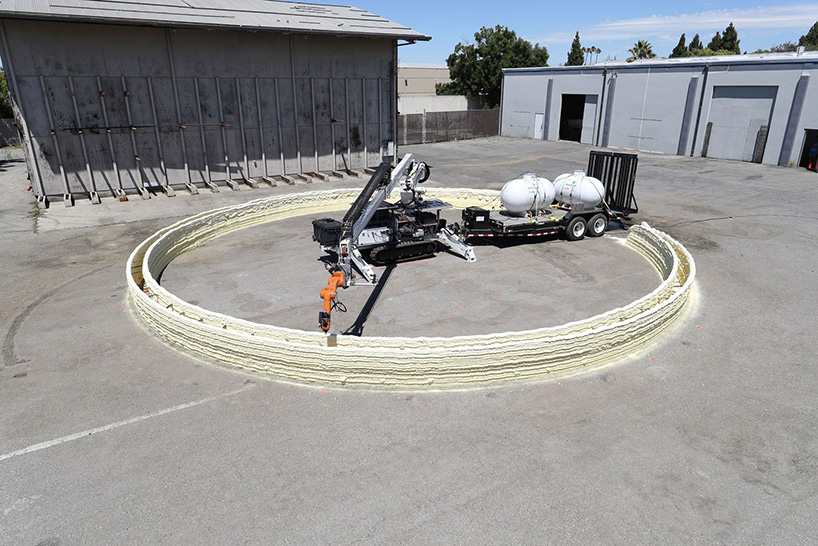

3D printed homes manufactured in only one day for 4,000$, this is the amazing project of New Story and ICON technologies. New Story is a housing nonprofit company, who already worked on reconstructing homes in Haïti, El Salvadore, after the 2010 earthquake.

The goal of these two companies is to create safe housing for people living in extreme poverty. ICON created a massive 3D printer called Vulcan. This Vulcan printer manufactured a 650 square feet house using a concrete material.

These kinds of homes can be built for millions of people, living in countries around the world.

A 3D printed house, built in only 24 hours

Additive manufacturing can build house faster than any manufacturing method! Apis Cor, a San Francisco startup 3D printed an entire house in only 24 hours in Russia. The company used a mobile 3D printer to make the entire structure of the house. This tiny home has been 3D printed on site. This impressive project shows how 3D printing could revolutionize the whole construction field.

Here is what the exterior and interior of this 3D construction looks like:

Credit: Apis Cor https://www.engadget.com/2017/03/07/apis-cor-3d-printed-house/

If you want to know more about this project and see some images of the printing process, you can watch the video below:

3D printed micro home

This one is also a kind of tiny home, of eight square meters. This 3D printed cabin is in Amsterdam. This project has been created by DUS Architects, a team of designers, architects, software programmers, inventors and 3D printing experts. They are all interested in design, innovations and sustainable housing.

This 3D printed canal house and its bathtub can be removed at any moment, and all the materials used for its construction can be reused. Indeed, this 3D printed micro home has been made with sustainable bio-plastic.

This project actually shows that 3D printing is the perfect solution to create a temporary home, easy to build, but also easy to remove. It has been printed using fused deposition modeling, an additive manufacturing technique used by most of desktop 3D printers.

https://www.dezeen.com/2016/08/30/dus-architects-3d-printed-micro-home-amsterdam-cabin-bathtub/

The 3D printed modular home

The Zhuoda Group in China 3D printed parts of a modular home. Six modules were assembled to create this surprising house. This is an entire house, with plumbing, kitchen and decoration. The construction company says that this 3D printed house is strong enough to withstand earthquakes, fire and water.

This is a perfect example to show what the future of apartment building could be. Indeed, 3D printed buildings can be assembled, they don’t have to be 3D printed in just one part.

Credit: https://www.3printr.com/zhuoda-group-unveils-3d-printed-modular-home-2729994/

The first 3D printed office building

Dubai’s Museum of the Future unveiled an impressive project in the United Arab Emirates. It took 17 days to print the whole building. One person was employed to use the printer, seven people were working on the components on site, and ten electricians were also working on this building. At least, the constructor save 50 percent on traditional labour costs to build this 250 square meters space.

This could be the workspace of the future! It is not only an experiment, this is actually a fully functional office.

This structure shows that additive manufacturing at a large scale is a good way to rethink the design of traditional spaces.

A large 3D printer of 6 x 36 x 12 meters made most of this 3D construction. Then smaller 3D printers were also used. This structure has been 3D printed in cement.

MIT’s 3D printing experiment

This experiment is an example of how 3D printing could help the construction field. MIT’s researchers created a large scale printer to create concrete structures. For the moment, this technology is not very accurate, but still, it is really promising and it shows how automated construction is already able to print XL concrete structures. It will certainly help construction housing.

Here is the MIT digital construction platform:

MIT digital construction platform https://www.designboom.com/technology/mit-dcp-3d-print-buildings-04-28-2017/

Ten 3D printed houses in one day: a real challenge

3D printing is leading to a lot of different experiments: manufacturers or researchers are always trying to break new records. Here is an impressive record.

The Chinese company WinSun Decoration Design Engineering built ten houses in only 24 hours. This impressive construction shows that 3D printing has some unbeatable advantages and can provide quality homes in only one day.They also worked on a new printing material made of cement, sand and fibre.

If you want more information about this project, check out this video:

The 3D printed villa

The company WinSun created other 3D printed constructions. For example, this amazing 3D printed villa, built in China. This home structure is 1,100 square meters. The quality and design of this 3D printed villais really impressive. Also, with this project we can see that 3D printing is not only useful to print tiny homes, it is totally possible to build large houses like this one.

https://3dprinting.com/news/winsun-3d-printed-giant-apartment-building-villa/

The 3D printed building

Here is another creation by WinSun: a 3D printed building! It is one of the world’s first 3D printed buildings, and it is quite high. The company is always using the same material that they developed for all of their constructions, using sand, concrete, glass and fibre. There are six apartments in this building, and it is quite high for a 3D printed structure. The building has been printed in separate parts and then assembled to create this huge structure.

Here is what this impressive 3D printed building looks like:

credit: https://3dprint.com/38144/3d-printed-apartment-building/

A 3D printed castle

In Minnesota, Andrey Rudenko created his own concrete 3D printer and built a castle… in his garden. This is a traditional large-scale 3D printer that deposits concrete layer by layer thanks to its robotic arm. This is not a full-sized house such as the 3D printed villa that we saw previously, this one is more like a playhouse for children. But it is still quite an impressive 3D printed house construction!

credit: http://www.totalkustom.com/3d-castle-completed.html

3D printed hotel

Andrey Rudenko built a 3D printed castle in his garden, but that is not it. Indeed, he went further with concrete 3D printing and also created a whole hotel suite with a 3D printed jacuzzi in the Philippines, using the additive manufacturing technology. It is also the proof that many different constructions can be made thanks to this technology: hotels, workspaces, homes, etc.

credit: http://www.totalkustom.com/3d-printed-hotel-suite.html

Promising projects of 3D printed houses

There are more and more 3D printed houses around the world. There are also a lot of projects regarding 3D printed houses, here is a selection of the most promising projects:

The 3D printed canal house

DUS Architects, that we saw previously in this blogpost with the 3D printed cabin, are also planning to build a bigger house: a 3D printed canal house that will look like this:

http://3dprintcanalhouse.com/

For the moment, on the building site, there is a lab and an exhibition. The aim is to find new solutions and make people think about new housing solutions. The team of DUS Architects is actually working on a software that could perfectly handle large scale construction, on the development of XL printers and on new sustainable 3D printing materials.

The Landscape House

Here is a great 3D printing project, with quite an ambitious design. As there was no 3D printer on the market able to print it, the Dutch architect Janjaap Ruijssenaars decided to make a whole 3D printer in order to build this structure. It will be 1,000 square meters.

He is developing a brand new technology with the Royal BAM Group in order to get the right 3D printer for his project. It is a 3D printer using sand which solidifies with a liquid. It will look like this:

credit: https://3dprint.com/138208/landscape-house-bam-3d-printer/

The 3D printed moonbase

The European Space Agency (ESA) actually plans to print a base on the moon. They are actually making tests to see if it is possible to 3D print on the lunar soil. Indeed, using additive manufacturing could be the perfect solution to build a base on the moon. The 3D printer of the Space Agency will 3D print the habitat layer by layer using regolith, a material that can be found both on earth and on the moon.

We will keep you informed of the achievement of all of these projects on the blog! So don’t forget to subscribe to our weekly newsletter, to read about all the latest 3D printing news.

For the moment 3D printed houses are not for everybody. Manufacturers and researchers are making experiments in order to show what it is actually possible to do thanks to 3D printing. The future of 3D printing in the construction field is actually promising, and hopefully, it will become even more common in the upcoming years! Printing companies could really create a sustainable solution to global housing crisis and participate to the creation of housing in developing countries. These 3D printed homes could be real affordable houses and could help people in countries around the world.

As you can see there are a lot of possibilities when it comes to 3D printing in the construction sector. Nowadays, a printer is capable of building 3D printed houses, pedestrian bridges, or any concrete structures.

You are working for an architecture firm or a construction company? If you are interested in 3D printing the model of any structure: you can upload your 3D file on our online 3D printing service.

Image: Ossip via Dezeen

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook