Top 8 of the best 3D printed art projects (2021 Update)

Posted By Jessica Van Zeijderveld on May 29, 2018 | 0 comments

3D printed art has set its own mark in the art industry by often grabbing the attention of the general public – such as Theo Jansen’s Strandbeest. But why do 3D printed art pieces become popular? This has to do with their complex designs and solution-based backstories. The designs are often so complex that even non-art connoisseurs know that traditional manufacturing methods or manual processes wouldn’t be capable of producing such art pieces. This blog post will explain to you the relation between art, 3D printing and product development by showing you six 3D printed art projects that each applied 3D printing differently. The concepts behind these art projects could be applied to a product line or to packaging design which could be beneficial for the design and product development teams during the development phase. In this blog post, we will first list down how 3D printing in art can result in new art applications. After that, we will show you some art projects that came to be with 3D printing. To end this blog post, we will tell you what future role 3D printing will take in the art world. You can then get started on your own 3D printed art or design project, here at 3D printing service Sculpteo.

Art, 3D printing, and product development

The reason why new artists are using 3D printing is a pretty obvious one that lies in the general concept of art. Art is an ever-changing idea that makes use of the latest manufacturing methods in order to showcase human-made expressions, creations, and imitations. Different production methods will visualize different ideas.

If we look at the history of art, we know that during the stone age, stones were not only used as a manufacturing tool for survival, it was also used as a tool for art and cave paintings. Cave walls in the same setting were then used as a canvas. In this day and age, 3D printing can be seen as the production tool and literal three-dimensional space can be seen as the modern day canvas. Additive manufacturing makes art unique because a certain type of technology is put in combination whilst creating an art piece. This technology does not only consist of 3D printing, but it also includes 3D systems, 3D modeling and 3D scanning. Of course, technology is quite often used for art but in this case, the 3D printing technology instantly affects the art during the development.

Art can come in the form of fashion too. We wrote an article about the best 3D printed fashion projects which can be found here. Art and design are always in correlation with each other. During the development phase of a product line or product packaging, the related design team and product development team can make use of 3D printing in a way that they won’t be limited in design, that they can make alterations to the packaging or product form on the go, knowing that they can make complex structures. Below you will find a proper explanation of the benefits:

Endorses creativity

3D printing in art unleashes the creativity that is cooped up in an artist’s mind. Often, when an artist tries to produce his art piece exactly like he had visioned it, he will be limited by traditional and manual production processes. When using 3D printing, the artist is not limited anymore by the type of production method. The only limitation is lack of knowledge in 3D modeling due to a 3D model being needed to print. Luckily, this is only a short-lived obstacle. There are many free and accessible resources for people to master 3D modeling in no-time. For example, you can take a look at our tutorial page where many different types of 3D modeling software are explained.

Groundbreaking designs

We already saw how 3D printing affects the film industry. Film is also a form of art that applies visual art with emotions. 3D printed film costumes are not limited in design and can even reflect a character’s personality better. This applies to static art as well. Static art pieces are sometimes designed in a way that strong materials are needed, e.g. when extremely thin walls are visioned. These walls can be so thin in fact, that the used materials would cave due to pressure. The reason why they would give in is that when the material was manufactured with traditional methods, they weren’t processed in a way where the whole of the art project is taken into consideration – resulting in weak points. 3D printing not only makes use of qualitative and strong materials such as metal 3D printing material, the 3D technology itself can create very thin and stable structures. Also, some art pieces need components that keep the art piece together. With 3D printing, these components can be directly applied or even be part of the actual art piece itself.

On the go alterations

Would regular manufacturing methods allow for you to customize or apply alterations on the fly? Sadly, not in most cases. Regular manufacturing methods often make use of molds. You would need to alter a mold if you want to alter your project. This is expensive and time-consuming. It would be possible to keep manually altering your art project by hand, but with restrictions. Quite often than not, manual alterations on the go lead to mistakes or unsatisfying feelings which in turn result in project abandonment. Also, once a mistake or unsatisfying alteration is manually made, it is permanent. With 3D printing, alterations are done inside your 3D file. It takes a minute to create a 2nd version of your original 3D art file. It then takes a fraction of a time to make the alterations and print it. If not satisfied with the new alterations, simply click the reset button – go back to your original 3D file and start over.

The best art projects

The below-mentioned concepts can be applied to a product line or to packaging design. During the development phase, the design team can make use of 3D printing in a way that they won’t be limited in design, that they can make alterations to the packaging or product form on the go knowing that they can make complex structures. Innovative artists have been using 3D printing for groundbreaking art projects. Below you can find some of these projects along with the process behind it and the used materials.

1. 3D printed sandstone spheres

Dario Santacroce is an artist that focuses on hybrid art and the creation of spherical objects. For his new art project, he visioned perfect spherical objects with a very smooth finish. According to Dario: “It is the first time these works and this technique will be shown to the public, so if you are wondering – yes this is a big deal, especially since with this new 3D technology I challenge Plato’s ‘theory of forms’ which states that perfect form can only exist in the realm of the mind. So I set out to make the most perfect spheres – is this possible?” This was achieved by 3D printing these spheres. He chose sandstone as a 3D printing material but he rapid prototyped his sculptures on a smaller scale with FDM first.

2. 3D printing in the comic book industry

mics are a form of art as well. The comic book industry is at the moment bigger than ever now that comics are transformed into major blockbuster movies. One comic book artist, David Wenzel, who worked for Marvel and DC comics, took comics even one step further from 2D print and 2D visualization over to 3D objects. He 3D printed his characters in order to showcase them at the largest comic con in the world. These 3D printed comic book characters were printed with full-colored sandstone to be then displayed to over 150.000 visitors.

3. A 3D printed re-creation of the Palmyra Arch

Even ancient art makes use of 3D printing. Terrorist organization ISIS destroyed the Palmyra Arch in 2015, a historical piece of art originating from the third century that was part of the world heritage list. CONCR3DE is a 3D printing service that uses a concrete material for 3D printing. In order to restore some of the Palmyra Arch, CONCR3DE 3D printed a concrete version of it. The team also made a 3D file of the 3D sculpture available for people to print it themselves. This is done as to spread the educational element of art around and to make art accessible for everyone.

4. 3D printing Indian art

Indian art is a very complex style compared to other art forms due to its design mostly consisting of curved and flowery concepts. Artist Naveen Kumar took up the challenge to actually create three-dimensional versions of Indian art concepts with additive manufacturing. Naveen’s goal was to combine traditional art styles with modern technology in order to address the fact that a traditional identity doesn’t have to be lost in a world with modern technologies. 3D printing is a perfect manufacturing method that is capable of respecting traditional values by being very accurate and thus honoring these values in its outcome.

5. 3D printing experimental art structures

Zaha Hadid Architects were pushing the boundaries of additive manufacturing art by 3D printing daring structures for Milan Design Week. Their ‘’Thallus’’ 3D sculpture has a complex floral design created by computer assistance. Computer assistance that created the design by generating complicated geometries. Thallus is made out of a strip that was 7 kilometers long and could have only been manufactured by a 3D printer with a six-axis 3D printing technology. These 3D printers are ideal for these types of designs.

6. Large-scale 3D printed artwork

Art can be manufactured on a large scale as well thanks to additive manufacturing. This is often done for pop-art which follows a sense of being somewhat kitsch. Artist Paco Raphael created this pop-art deer piece. This deer is highly detailed and 3D printed on a large scale which is common for pop-art where the boundaries are tested between art and generic mass-produced objects. Paco’s reasoning for 3D printing his art piece on large-scale is due to wanting to put the deer in multiple urban places such as New York City, where elements of nature are missing sometimes.

7. 3D printing impressive skeletal structures

Joshua Harkey is one of the most famous artists in the 3D printing world, known for pushing the boundaries of the 3D technology and create impressive 3D printed structures. This 3D artist is using CT scans to 3D print skeletal structures, by digitally scanning, he can create 3D printed models that are both accurate and experimental.

Joshua Harkey explains: “My art is about pushing the limits of form & dimensions to share my visions… an exploration into what can be made & how to accomplish it in effort to tell a story or create an experience. I incorporate digital tools, software, & technology as well as traditional mediums in my work to create art that is both exciting & engaging. My work is fresh, imaginative, & cutting edge.”

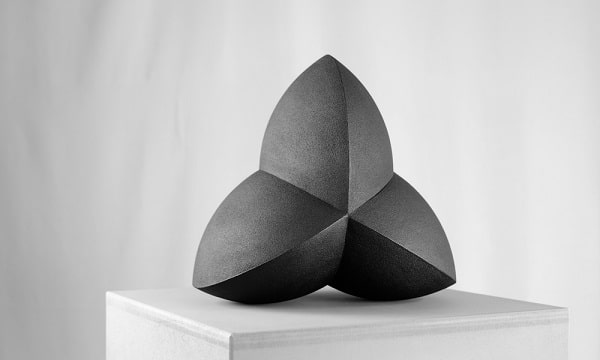

8. 3D printing art with ceramic

Kate Blacklock is an artist using 3D printing to recreate pottery. Her work is creative, delicate and accurate. 3D printing is offering brand new form of freedom to artists in terms of shapes and geometries.

Kate Blacklock

3D printed art: the future?

Art will always make use of the latest manufacturing methods in order to set new boundaries. In the future, 3D printing will improve even more and will make use of new materials. It is already possible to 3D print with concrete materials and even molecules! We can only expect for artists and designers to see this inevitable development and be curious to see how it can be applied to art. When you 3D print your art you won’t be limited in design; you can make alterations on the go; you can make complex structures and you will likely create exactly what you visioned in mind. Art goes hand in hand with product development and packaging design. Each one of the above-mentioned applications can be applied to your business as well. Sculpteo has the means to help you produce what you have visioned. Simply upload your 3D model here, and expect your art project within days. If you want to keep up to date with additive manufacturing and new materials that can be applied to 3D printing which in turn can be potentially used for art projects, subscribe to our weekly newsletter!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook