What happened in the 3D printing world in 2019 ?

Posted By Lucie Gaget on Dec 23, 2019 | 0 comments

Every year, additive manufacturing offers new opportunities, and new amazing projects are unveiled. Thanks to all the companies and researchers believing in the capacities of this game-changing technology, 3D printing once again helps to overcome new challenges in various industries.

What happened in the 3D printing world? What happened at Sculpteo? Let’s take a look back at this amazing year in the world of 3D printing.

Medical 3D printing

The medical sector is one of the most promising sectors for additive manufacturing. Medical 3D printing is becoming more and more common, offering brand new possibilities for both doctors and patients. What were the main areas of progress in this sector in 2019?

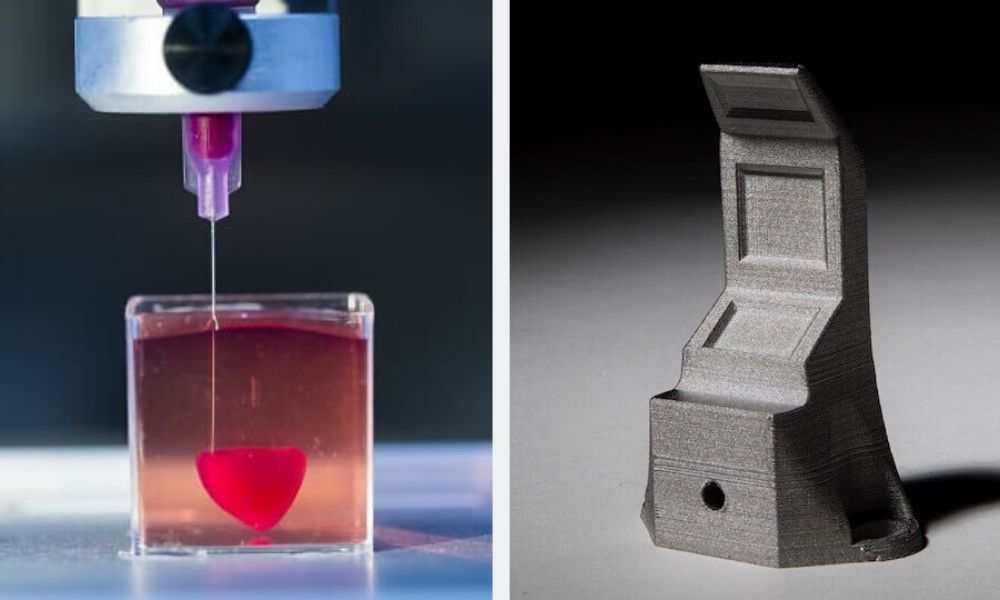

The first 3D printed heart with tissue

We already know about 3D printed organ models helping surgeons to prepare their surgeries, some human organs could directly be 3D printed in the future. In 2019, the first 3D printed heart with human tissue has been created. The use of human cells to 3D print a vascularized heart is completely new and this heart has chambers, cells, and blood vessels.

Professor Tal Dvir from Tel Aviv University’s School of Molecular Cell Biology and Biotechnology and Sagol center for Regenerative Biotechnology led this amazing research.

As he explains: “This heart is made from human cells and patient-specific biological materials. In our process, these materials serve as the bio-inks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models. Ideally, the biomaterial should possess the same biochemical, mechanical and topographical properties of the patient’s own tissues.”

https://www.businessinsider.co.za/Israeli-scientists-print-first-3D-heart-586902

The 3D printed bionic pancreas

This new 3D printed pancreas is quite special: it has blood vessels and is produced with the patient’s own cells, which limits the risk of rejecting the organ! What we call here the bionic pancreas couldn’t completely substitute the organ for the moment, but it could restore insulin production.

Researchers actually came up with a mixture of pancreatic islets from animals and bio-inks, and these bio-inks supported the 3D printed cells. One syringe of the 3D printer displays the mixture, and the other one creates blood vessels. Dr. Wiszola, a scientist from the Foundation for Research and Science Development in Poland affirms that: “No one has yet founded a solid organ with full vascularisation”. This pancreas in interesting to treat diabetes!

The 3D printed lung

This 3D printed organ is not made with human cells but is still offering new opportunities for organ transplants. The 3D printed lung developed by Jordan Miller, assistant professor of bioengineering at Rice’s Brown School of Engineering and his team is the proof of concept. Why is this proof of concept so interesting for the medical sector?

This 3D printed lung is quite impressive because it’s fully functional and the device can contract and expand in order to pump air, just like real lungs.

3D printed equipment for tetraplegic athlete

Customization is one of the most interesting benefits of 3D printing, it can be used to create made to measure prosthetics for example, or even adapted sports equipment for paralympic athletes!

Florian Jouanny is tetraplegic, and he is actually the first tetraplegic athlete to finish the Ironman Triathlon. The athlete was still struggling to grip the handles of his handbike due to his paralysis. Additive manufacturing helped him to create the perfect handles adapted to him, and helped him to focus on his performance.

Additive manufacturing breaking records

Some companies and 3D printing users are already fully aware of the possibilities offered by additive manufacturing, but they want to show it to the world, push the technology’s limits and break records.

Indestructible metal 3D printing

Additive manufacturing is also a good manufacturing technique to improve and optimize products that we already know. 3D printing is then becoming an added value, giving the product new properties.

An indestructible 3D printed guitar has been printed in order to show the robustness of metal 3D printing technology. This guitar is made to be smashed, and it is presented as indestructible. Designed by Andy Holt and manufactured by Sandvik using titanium 3D printing and DMLS technology, this indestructible 3D printed guitar has been tested by the virtuoso Yngwie Malmsteen.

The longest 3D printed bridge

3D printed bridges are not a new thing, but in 2019, the longest bridge ever printed opened in Shanghai. Xu Weiguo designed this bridge based on an ancient bridge that was built during the Sui Dynasty (581-618 CE): it took 11 years to manufacture this bridge. Thanks to additive manufacturing technology this new structure has been built in only 450 hours.

https://www.3ders.org/articles/20190116-worlds-longest-3d-printed-bridge-opened-in-shanghai.html

The 3D printed boat

Large scale 3D printing is becoming more and more popular, and it actually allowed to print one of the biggest objects ever printed. The 3Dirigo, 3D printed boat.

A team of researchers used a large-format 3D printer developed by the UMaine Advanced Structures and Composite Center. The biggest part is actually 7.62 meters long and has a weight of 2.2 tones! This boat is impressive and broke some records: the largest 3D printed solid part, the largest 3D printed boat and finally the largest 3D printer.

Space and 3D printing: Still going further!

NASA is using 3D printing on many different levels, to print tools directly on place, or to print engine parts. But this year, some new developments have been made for the future of space and additive manufacturing.

NASA 3D printed habitat challenge

A few years ago, back in 2014, NASA launched its 3D printed habitat challenge on Mars. Competitors had four years to develop a habitat meeting some specific requirements.

The winner has been announced this year, and it’s AI SpaceFactory, from New York. The whole structure created by AI Space Factory is long and vertical, which was explained to be the best for Mars’ surface. The structure would be 3D printed with Martian soil and bioplastic, which is an ecological process and eliminates the transportation of a lot of materials from space stations! The whole habitat is divided into sectors committed to different daily activities.

The 3D printed steak

3D printed meat has already been experienced in the past years, but this time, these 3D printed steak developments are going further. Aleph Farms, an Israeli start-up proudly calling themselves meat growers who are able to produce a steak in space! Why are they producing steak in space?

Actually, Earth’s gravity is difficult to work with when it comes to bio 3D printing, meaning that they have to work with lattice supports to print meat. In space, with no gravity, conditions are perfect to print meat without any support.

What happened at Sculpteo?

2019 was also a big year for Sculpteo’s online 3D printing service.

State of 3D printing 2019

This year we launched our 2019 edition of the State of 3D printing. Each year this study allows us to see what are the main trends in the 3D printing world, how is additive manufacturing actually used by professionals all around the world. This year, we made the largest report yet with over 1 300 respondents. We also took a better look at Women in 3D Printing. Also, we dig deeper into the Job Market sector.

You can still download our report for free!

BASF Acquires 3D Printing Service Provider Sculpteo

This year, the German chemistry company and largest chemical producer in the world, BASF has acquired Sculpteo. This acquisition will drive market growth, provide additional sales channels for BASF customers and offer new materials and technologies for customers of both BASF and Sculpteo!

Sculpteo now offering J+1

Sculpteo is offering a J+1 shippingfor all customers located in Île-de-France, to help you with your 3D printing projects. Download our guide for more information.

What are your 3D printing highlights of 2019? Share them with us!

Do you want to start using 3D printing and find new opportunities for your business in 2020? Take a look at our online 3D printing service!

Don’t forget to subscribe to our newsletter to receive all the latest news about the 3D printing industry.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook