We talked a lot about the benefits that Additive Manufacturing brings to the construction industry. 3D printing opens new design possibilities, reduces costs, and produces sustainable construction projects with low environmental impact. We talked about theory before. Now let’s move on to how the advantages of AM are applied in reality!

We already told you about a family moving into a 3D printed house in France and many 3D printed houses projects. In the other real-life examples, we will introduce you to some stunning projects from the Netherlands, Dubai’s 3D published offices, and the first-ever 3D printed bridge. How about manufacturing a house in one day? Is it possible? Let’s see how far the 3D technologies for the construction industry have come.

Build a House in 24 hours?

Why not! Apis Cor is a Russian company specializing in 3D printers that can produce a contour-crafted home in just 24 hours. Not only that, but the machines can also work in winter. They have to be covered. 3D printers can be easily transported to the building site, and within 30 minutes, it’s ready to build your future house! The concrete is a unique mix that hardens fast, allowing the printer to work quickly. The company wanted to showcase also that the shape of buildings doesn’t have to be square. We can open architecture to take new forms. Experiments like this show that additive manufacturing could become a serious solution to the housing crisis in the upcoming years.

3D printing a new life

New Story is a nonprofit organization aiming to bring homes to the poorest. They have built 850 houses worldwide in 3 years, but they knew they had to work faster. Brett Hagler, the CEO and co-founder of New Story saw the potential of Additive Manufacturing. They developed new designs and construction solutions, improving their building process and reducing costs. Thanks to 3D printing, they could manufacture 100 contour-crafted homes in just eight months. That’s more than 12 houses per month, and for the organization, that means 12 families that finally received homes.

New Story achieved many thanks to collaborating with Icon, who designed the Vulcan mobile 3D printer. The machine can be easily moved to developing countries and can operate without electricity. The printer can build a 600 to the 800-square-foot house (55- 75 square meters) in just 24 hours. Thanks to 3D technologies, the costs are established to be just 4 000$. This can truly change the future of housing and fighting homelessness.

https://www.artsy.net/article/artsy-editorial-inside-race-perfect-3d-printed

An innovative form of offices: building offices of the future

3D printing brings new forms into construction. Thanks to Additive Manufacturing, the architects are no longer limited to abstract forms of the office building, and Dubai’s new offices proved that. They produced new, futuristic structures in just 17 days by 17 professionals. They are equipped with energy-saving devices, which are very cost-efficient. But also, 3D printing for construction has already reduced labor costs by 50%! Utilizing Additive Manufacturing allowed for massive cost reduction and was much faster than the traditional building process.

https://inhabitat.com/dubai-debuts-worlds-first-fully-3d-printed-building/

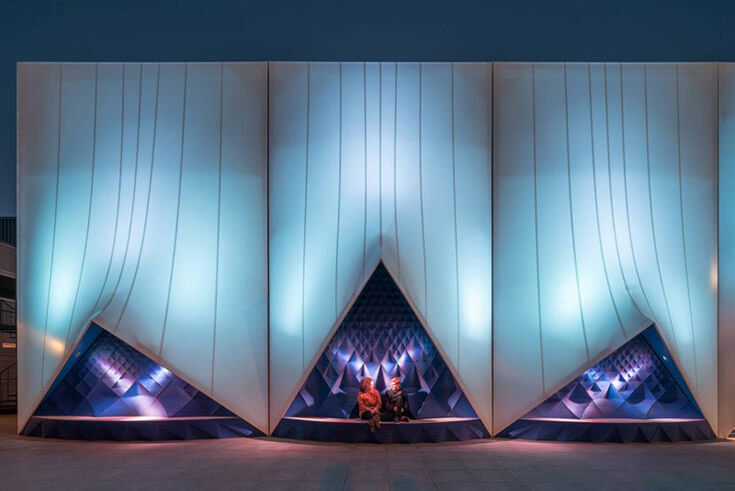

Stunning and marine-inspired facade

In 2016 the Netherlands was holding the Presidency of the Council of the European Union, and celebrating such important leadership, a new facility was built for the politicians to gather. It was not just an ordinary, bland building. Given new design freedom by 3D printing, the architects constructed the elegant facade, resembling a sail stretched over the building.

The curtain-like slits uncover blue benches, which were 3D modeled geometrically and manufactured locally with a construction 3D printer. This innovative structure was produced with bioplastic, which was developed especially for this occasion. When the Dutch EU Presidency ended, the building was taken apart, and the bioplastic was recycled to be reused for future 3D printing projects. This proves the construction industry can have low environmental impact thanks to 3D technologies.

https://www.detail-online.com/blog-article/3d-printed-europe-building-by-dus-architects-26804/

3D printed bridges

Additive Manufacturing in the construction industry is not just about buildings. Applications of 3D printing can also be highly beneficial to manufacturing bridges. Thanks to the ability to create some complex structures but also build solid and durable constrictions. We just wrote about the longest 3D printed bridge in the world published recently in China!

But it wasn’t the first pedestrian bridge ever. The pioneers in 3D printed bridges were the Netherlands. The construction in question was built for cyclists. Thanks to Additive Manufacturing, it could handle the weight of 40 trucks, and thanks to Additive Manufacturing is sustainable! The Netherlands seems to see the potential of 3D technologies as the next project is also Dutch.

This bridge came to life with 3D technologies and was designed by MX3D. The company developed a unique robotic arm capable of 3D printing with steel. This impressive construction has an abstract and bio-inspired design, and the bridge builds itself thanks to the 3D software the engineers elaborated.

3D printing homes with rice?

Additive Manufacturing is a great way to bring more sustainable architecture to life. Wasp, an Italian 3D printer manufacturer, developed the Gaia project. They manufacture contour-crafted buildings with almost no material waste. The material used is raw earth and rice waste, both of which we have plenty of. The structure of the walls allows for thermal insulation and natural ventilation. This project perfectly showcases the possible eco-friendly and fully functional architecture thanks to 3D printing.

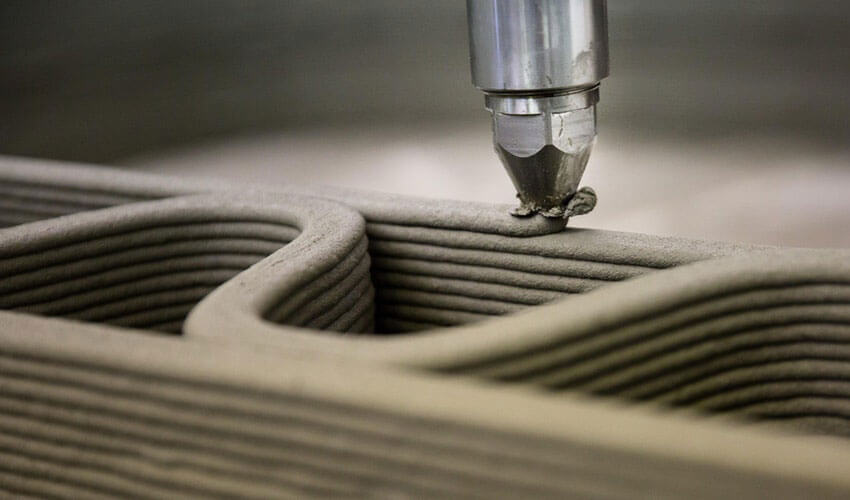

Concrete 3D printing

Eindhoven is known for its many 3D printing concrete experiments. But do you know that a project of 3D printed concrete houses is planned in Eindhoven? This project will start to be 3D printed at the Eindhoven University, using concrete 3D printers, and move progressively to the construction site. The goal here is to allow the construction of delicate architectural designs while keeping in mind some sustainability aspects by avoiding material waste and CO2 emissions.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook