Our guide Industrial applications of 3D printing

Posted By Sculpteo on Mar 15, 2017 | 0 comments

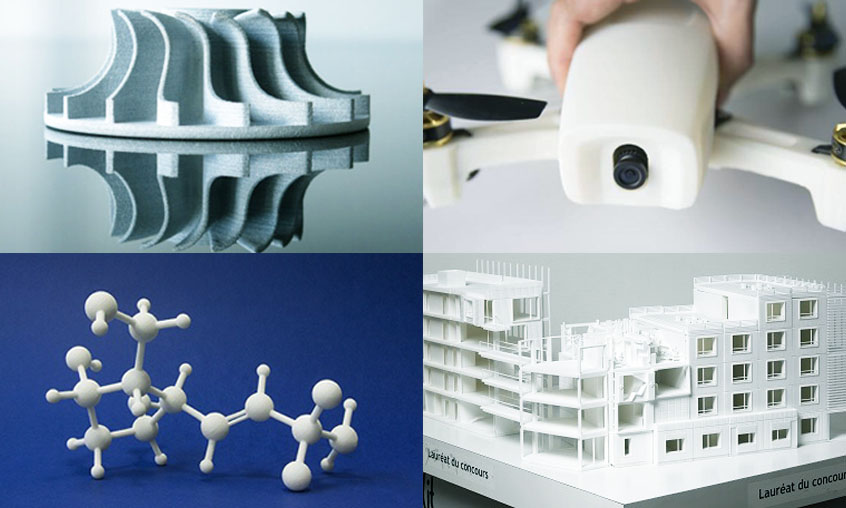

3D Printing is creating new opportunities in a wide range of sectors, enabling easier prototyping processes, renewed approaches of the production line (remote production, cheaper small batch production, reduced tooling and machine costs, use of online 3D printing services…), and designs that were impossible before. We’ve been writing about 3D printing and the advantages it brings to various industries on this blog, and today we give you a summary of the applications and benefits of:

- 3D printing in the High Tech Industry

- 3D printing in the Entertainment Industry

- 3D printing in the Automotive Industry

- 3D printing in the Fashion Industry

- 3D printing in the Chemical Industry

- 3D printing in the Medical Industry

- 3D printing in the Construction and architecture industry

3D printing in the High Tech Industry

3D printing advantages for the high tech industry

By enabling faster and cheaper prototyping, and easier access to small and medium batch production with no investing in molds and tools, 3D printing makes it possible to for high-tech companies to test their product to the market with less risk involved, and improve it progressively, to match the market’s expectations to the closest. The use of online 3D printing services enables small companies to prototype and produce without investing in machines.

A few examples

The company AudioQuest created high-tech headphones, The NightHawk that use DCL grille design, a complex shape that wouldn’t be possible without. It increases the acoustic properties of the headphones.

Drones are another good example of how 3D printing opens the way to unlimited customization and easy production. Read our customer stories: Nano-Racing and UVify Racing Drone.

3D Printing in the Entertainment Industry

3D printing advantages for the entertainment industry

For the entertainment industry, 3D printing models and figurines are more and more widely used by games but also many movies and animation studios, as well as various artists. 3D Printing a figurine of a specific hero, character or accessory from a movie or game can be used as a teaser for a project in development (having the character in hands can be a plus for potential collaborators), to present on salons and conferences, or to sell directly to fans. And of course, the great freedom of design allows artists to create in new ways. 3D printing can also be used, like in other industries, for prototypes (of tools, props, etc.), to create complex and customized shapes, or even for production of sets and characters (for animation, as you’ll see in the example below).

Read more in our article “How 3D printing is revolutionizing the entertainment industry”.

A few examples

American stop-motion animation studio, LAIKA which is known for its films such as Coralie, ParaNorman and The Boxtrolls has been a leader in bringing 3D printing into the process of stop-motion animation. From the Oscar Nominated movie of 2016 Anomalisa, it used 3D printed faces with interchangeable expressions for their animated puppets.

One of the creators of the game, Lily, colors of Santa Luz, Florian Coudray, also told us in an interview it was a great help to be able to 3D print a figurine of their main character to give life to her and promote their award-winning student game. It is one of a good example to explore about these two industries. Read more about it on this blogpost.

3D printing in the Automotive Industry

3D printing advantages for the automotive industry

Another industry that keeps evolving and taking advantage of 3D printing is the automotive sector. 3D printing is used for car prototypes, for spare parts, to create complex parts within “traditionally” manufactured cars, and even, to create whole cars!

You can read more in the article ‘3D printing transforms the automotive industry’.

A few examples

In 2015, the car manufacturer Audi experimented to produce some complex metal parts with 3D printing. The purpose of this experience was to demonstrate that additive manufacturing would lead to cost and time reduction. Knowing the advantages of 3D printing, they wanted to adapt the old process of manufacturing using different technologies (DMLS or EBM) to avoid waste in production.

Ford, another car manufacturer has announced that they will use 3D printing in the development of Ford GT Supercar. The most noticeable aspect of this announce was that the company will use 3D printing for both concept and production cars and also for prototyping.

3D printing in the Chemical Industry

3D printing advantages for the chemical industry

One of the industries that invests the most in R&D is the chemical industry. As companies keep searching for breakthrough innovations, 3D printing enables them to go even further and may lead to real revolution for this sector. It helps produce cheaper, customized tools, as well as brand new innovations.

Some examples

Martin Burke, a specialist in small molecules synthesis, along with his team, created a molecule-making machine. This invention is able to produce automated chemical 3D printing, allowing the faster and simpler way to assemble a small molecule like a building block. Each of the blocks contains its own property that shares connector piece which with this machine can obtain new molecule in easier way.

Explore this short and yet very interesting video about M. Burke and his machine.

What’s interesting is that it also goes the other way around: chemical innovations help move 3D printing forward. Indeed, 3D printing is highly depending on the materials it uses and how to morph them. A good example is Carbon’s CLIP technology, which pushes 3D printing’s speed limits with a new way to morph a material into a final object.

3D Printing for the fashion industry

3D printing advantages for the fashion industry

3D printing is revolutionizing the fashion industry, inspiring creative designers to include the technology into their concept and creation. The benefits in connecting 3D printing into the retail and fashion industry is that it enables to create new styles and unique shapes using the new material. It can also allow cheaper, faster custom-made clothes. Furthermore, adding 3D printing into the fashion world impacts the process of supply chain.

Some examples

Danit Peleg, one of the first 3D printing clothes designers, imagined a future where people will be able to 3D print their own clothes directly at home. If so, what will be the challenge in fashion industry? It might create ‘Eco-friendly’ alternatives, by reducing the material waste and the transportation emissions.

It probably would push the industry to create ‘User-friendly’ platforms and technology, since making 3D modeling accessible is a key issue before realizing the vision where everyone can print their clothes on their own. One can imagine a future in which fashion designers create the 3D files that will be directly sold to customers or retailers, who can 3D print their clothes directly.

You can read our article about 3D printed Clothes: Fashion Designers create wearable garments.

To give another example: the designer Anastasia Ruiz, created, in partnership with Sculpteo, the Virus Collection, almost entirely conceived and produced thanks to additive manufacturing.

Virus collection 3D printed samples

Credits: Clausette.cc

3D Printing in the Medical Industry

3D printing advantages for the medical industry

In the healthcare sector, Medical 3D printing has revolutionized the industry in which it helps for very practical purposes such as creating tools and prosthesis (or their prototypes), and innovative solutions for implants. It also gives patients the advantage of customization that can have great results for the quality of life. You probably have heard, also, of even more impressive applications, of 3D printing skin, organs, and even bone!

Some examples

In inaccessible areas, medical equipment is limited, which is a problem since the medical surgery needs lot of materialized tools to work. 3D printing can provide a solution to this problem since medical tools can be manufactured in a less than a day using 3D printing.

To learn more, read our article about ‘7 things that Medical 3D Printing can do‘

3D printing is used by our customer Spinevision to create prototypes for their medical tools and implants, and improve their products’ quality. Spinevision is also looking into producing these tools and implants directly in 3D printed titanium (they just need medical grade 3D printed titanium).

You can read more on 3D printing in the medical industry with our interview of Spinevision’s R&D teal.

3D printing for the construction and architecture industry.

3D printing advantages in the construction industry

As some may know, 3D printing is on its way to become a necessary tool in architecture and construction. On top of the advantages provided by 3D printing architectural models, more and more people imagine and start experimenting with buildings, projects and concepts in construction using layer by layer building machines. Some benefits offered by making 3D printing and construction industry meet are: a reduction of material waste, faster and cheaper construction of housing (which could make housing more affordable for the less wealthy) and the invention of innovative shapes.

Some examples

Using the Contour Crafting System developed by Dr. Behrokh Khoshnevis, a family house can be printed within 24 hours. The result is a really safe house, as solid as rocks, and most of it, a house that will last indefinitely. Based on that success, a project to build a skyscraper from 3D printing technology is born. However, the question is, whether the technology can adapt and be implemented for taller structure.

Neri Oxman, another influencer in 3D printing innovation, imagines a new way to structure cement, so that it is more resistant, with less material.

Companies like the French startup XtreeE are already starting to build using 3D printing in public spaces. XtreeE uses an innovative method to 3D print directly in concrete. But as founder Philippe Morel explained to us in an interview, the main limitation left for 3D printing in construction is a legislative one: 3D printed buildings don’t have specific legislations yet, and won’t be covered by regular insurance. It’s a legal innovation that is yet to follow the scientific and technical innovation!

We hope this combination of the 3D printing applications in various industries inspired you to start your own 3D printing endeavor. If it did, you can upload a file right here.

If you liked this article, please feel free to leave a comment and to share it on Facebook, Twitter and Linkedin

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook