Top 10 of the best 3D printing prototypes

Posted By Kat Plewa on Dec 19, 2018 | 0 comments

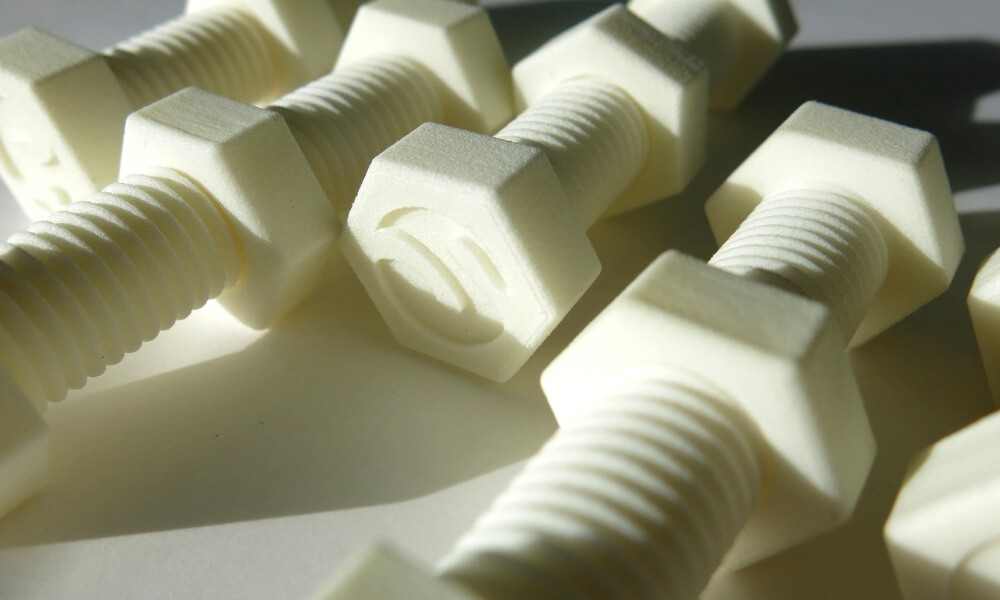

Additive Manufacturing has numerous applications, and one of the most known is 3D printing prototypes. This technology provides you with a wide range of materials, absolutely new design freedom, and at the same time, the results are fast and cost-effective. What are the most interesting ways to use 3D printing for prototyping? Let’s find out!

What are the benefits of 3D printing prototypes?

Above all, Additive Manufacturing is fast and produces your prototypes in no time. That’s an obvious advantage as time is money, especially when it comes to prototyping. The faster you can test new design solutions, the quicker you can adjust your design and move on to the manufacturing process of your final product.

Secondly, it gives you a lot of design and material freedom, allowing you to match the technology and material to your design, not the other way around. With 3D printing, you can test your parts with various plastics, flexible and heat-resistant materials, and even metals.

Additive Manufacturing is also great to produce jigs and fixtures, as we’ve talked about in previous blog posts. They are very important parts of the whole device and need to go through functional tests to fit and function perfectly. 3D printing allows for quickly prototyping new ideas to improve the designs. Let’s see some real-life examples of 3D printing prototypes!

Top 10 of the best 3D printed prototypes

Did you know that such big companies as Ford already use Additive Manufacturing? The potential of 3D technologies is great and no one waits for their competitors to take advantage of them. One has to move on with the most innovative technologies to keep up with the race of manufacturing the best quality, the fastest.

3D printing prototypes for car races

Team Penske is well respected in the car racing industry for over 50 years. It is an American professional stock car, open wheel, and sports car racing team. In this field, time is the most crucial element. They constantly work on improving their results and speed up the wheel changing process. This involves different manufacturing tools and machinery, which means a lot of functional tests.

Thanks to 3D printing prototypes their work is much more efficient. The period form design to prototype was shortened to just a few days, and as for 3D printing, prototypes to just one day. This is an essential and absolutely the most important aspect in Team Penske’s work. If you want to win the race, you have to be the fastest and Additive Manufacturing is the innovation they needed.

3D printed eyewear

Another industry benefiting from Additive Manufacturing is eyewear. 3D printing gives them new possibilities when it comes to materials, and can produce highly precise prototypes ready for testing. Again, 3D printing prototypes is also very fast, which speeds up the whole production process. Additive Manufacturing is an excellent technology not only for prototyping glasses but also for the actual production, as is proved by Octobre71, one of our clients.

Full-scale 3D printer furniture prototypes

We already talked a lot about 3D printing houses or architectural models, but 3D printing prototypes in the field of furniture design is also growing rapidly. With Additive Technologies the designers are able to produce fully functional prototypes and visual models overnight and then functional tests of the new solutions for finishing final products.

We don’t realize how many elements have to be approved for even simple furniture. Take a chair- it has to be not only comfortable but also has to consider the right height, width, and weight capacity, as well as the materials. Those are just the basic needs, you can see how important the prototyping stage is to get the final product right.

Bridge competition

We already know that 3D printing bridges is totally possible. But 3D printing prototypes of them is also very interesting. Gdansk University in Poland decided to use Additive Manufacturing for a competition to develop the best bridge design. The visual models were printed on the day and allowed to quickly reveal the result of which bridge construction has the best quantities. The bridges were printed on a scale and went through functional tests for the load and stress they can handle.

Thanks to 3D printing prototypes, they will be produced in no time, you can test the strongest points of your design, and which parts of the construction are the weakest and need improvement. 3D printing prototypes is the way to go if you need quick and accurate results.

Prosthetic arm prototype

The applications of Additive Manufacturing in the medical industry are numerous. From 3D printed skin or jaws to drug testing. Another amazing use is 3D printing prototypes of different prosthesis. Designing one is definitely a challenge, but can improve the quality of life in a way we can’t imagine. There are a lot of things to take into consideration, for example how the motors will be installed, how to operate the hand. 3D printing prototypes is very fast, cost-efficient, and allows to quickly test different design solutions.

Also, thanks to Additive Manufacturing technologies, the prosthesis can be highly customized, matching exactly the needs and measurements of the patient, which is absolutely essential. 3D scans are already used to get the most accurate image of the limb, so then the socket can be fitted perfectly, not causing any discomfort for the user. Then, doctors are 3D printing prototypes and can easily check which parts have to be adjusted.

3D printing motorcycles

We recently introduced you to a fully functional, 3D printed motorcycle which was presented at Formnext. But it’s not the only example in this industry. The company, Lightning is also staying ahead with the most innovative production solutions. They produce electric motorcycles that perform at least as good as the gas ones. Additive Manufacturing plays a key role in the manufacturing process.

Richard Hatfield, the CEO, explains that the first stage is 3D printing prototypes in quarter scale to check the visual aspects of the design. When they reach a satisfaction point, they 3D print the parts in full scale. This highlight the importance of using Additive Manufacturing in their production process, from the idea to the final product, Hatfield says that this whole process is as short as one week.

3D printed prototypes by Ford

Ford is one of the big fish in the automotive industry. Their engineers saw the potential of Additive Manufacturing and moved their prototyping stage into a new era. Now, 3D printing prototypes, such as a dashboard, is cheaper, and much faster. After the design stage, they can quickly produce the part and test its efficiency and other capabilities. Additive Manufacturing is really a game- changer for rapid prototyping and the automotive industry is making the most of this technology.

TeeMate- your 3D printed golf friend

Automotive is not the only industry that benefits from Additive Manufacturing. 3D printing prototypes of sports equipment is also becoming more and more popular. Thanks to 3D technologies new devices are produced quickly, at the same time with low production costs, and they are highly customized.

The latter advantage of 3D printing is definitely what Two Brothers 3D Printing Solutions (2B 3D) brought to this technology. They’ve decided to help golf players, for whom picking up the tees and the ball presents quite a struggle. Continuous bending can cause a lot of pain in knees, so 2B 3D came up with TeeMate- a picking up device. It is custom made for golf player’s needs and helps not only to retrieve the tee and ball, but also to place them in the ground.

Puppet eyes

Using Additive Manufacturing is a great solution for mechanical parts and they can be found even in puppets! Zuckerli’s puppet workshop gives their viewers the most realistic shows and to make that happen, the puppets have to move their eyes. They developed a prototype of puppet’s eyes, which allows moving both of them with just one finger. Thanks to 3D printing, they were able to test different solutions and mechanism to match their needs the best.

World’s first 3D printed titanium wheel

Last, but not least, HRE Wheels and GE Additive totally dominated the use of 3D printing for prototyping. The traditional way of manufacturing wheels is expensive, produces a lot of material wastage and is time- consuming. On top of all of that, it doesn’t give much of design freedom.

To face those obstacles and change the way we manufacture wheels, designers and engineers from GE moved towards 3D printing. With this technology, they were able to test totally new materials, analyze them and with the results- redefine the wheel production. Additive Manufacturing also eliminates many manufacturing tools normally needed to produce a wheel, which not only saves time and lowers the costs, but also gives totally new design freedom. The company improved the production process so much that they even moved forward with manufacturing the final product using 3D printing!

Should you start 3D printing prototypes?

Yes! As you can see, Additive Manufacturing brings endless benefits for your manufacturing process. From new materials, the capability to produce complex geometries, to much shorter production time and cost reduction. It is time for you to make the most of 3D printing. Start with us, it is as simple as uploading your 3D file to our online 3D printing service!

And don’t forget to sign up for our Newsletter for the latest 3D printing news!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook