17 oustanding 3D printing facts

Posted By Lucie Gaget on Oct 30, 2019 | 0 comments

You may already use 3D printing but here are some great facts you may not know about 3D printing. Indeed, as a 3D printing service, we can see every day that people have misconceptions about this cutting-edge technology! That is why we made this article for you, about the incredible and diverse applications of additive manufacturing, showing you the full potential of this technology.

Are you ready to see what 3D printing can produce? Discover some amazing 3D printing facts and get inspired to give life to your own 3D printing projects!

3D printing is older than you think

Additive manufacturing is often seen as a really new manufacturing technique. But this technology is actually not that new. We can say that 3D printing made kind of a buzz in the 2000s when the general public discovered FDM (Fused Deposition Modeling) technology and nylon filament. But the birth of additive manufacturing is way older than that! First 3D printing experiments and patents appeared in the ’80s

3D printing is a French invention

Indeed, the creation of 3D printing kind of started in France. Jean-Claude André, Alain le Méhauté and Olivier de Witte registered the first patent for this game-changing technology in 1984, but everything didn’t go as expected, and we often credit the American Charles Hull for this innovation. To read the full story, check out our interview with Jean-Claude André, one of the 3D printing creators.

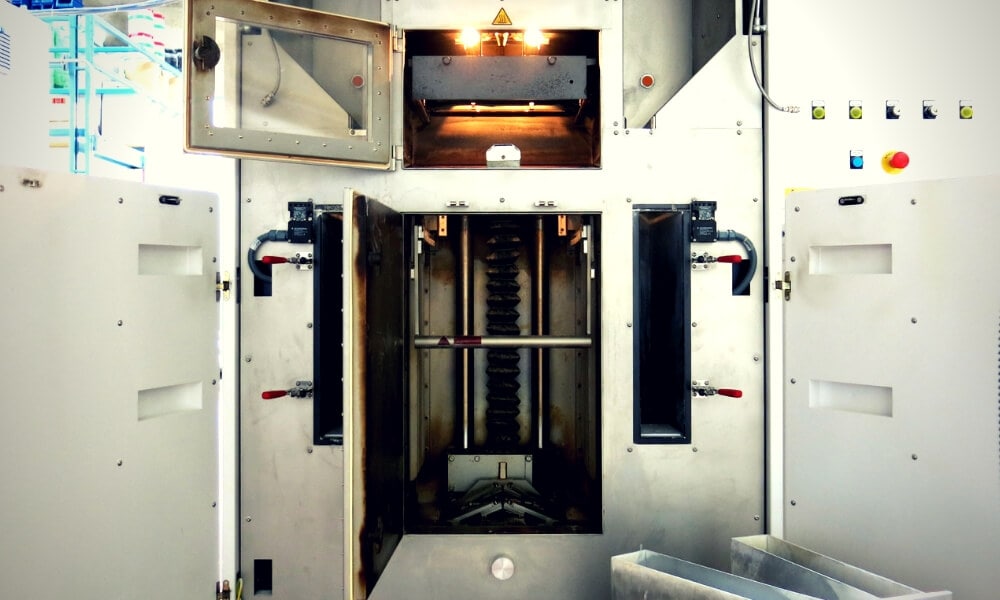

There are numerous 3D printing techniques

People often associate 3D printing with FDM technology and desktop 3D printers, but there are actually various types of 3D printing processes. But that is not the only 3D printing technology. As you can see on our online 3D printing service, we are offering multiple technologies such as SLS (Selective Laser Sintering), HP Multi Jet Fusion, DMLS (Direct Metal Laser Sintering), SLM (Selective Laser Melting), DLS (CLIP), etc.

From plastic to metal and resin, there are different 3D printing processes and even more 3D printing materials available on the market.

3D printing is not only a prototyping technique

3D printing is mainly seen as a prototyping technique. And indeed, it is a very good way to make some rapid prototyping and create functional prototypes, but not only! Additive manufacturing is more and more used for production. Each year, we study the evolution of the uses of additive manufacturing by companies, with the biggest report of the additive manufacturing industry, the State of 3D Printing.

In this report we can notice that year after year, 3D printing is used for more and more different applications by companies. And we can clearly see that a growing 51% of respondents apply 3D Printing technologies for production. This technology is actually more and more used for production purposes!

3D printing materials are more numerous that what you think

We just told you about the numerous 3D printing techniques actually available in the industry. But the industry is also flourishing on the material side. If plastic, metal, and resin, are offering great opportunities. Researchers are developing new material, so this technology can answer all needs possible. 3D printed wood, ceramics or 3D printed meat. Yes, materials possibilities are endless.

Additive manufacturing saves lives

3D printing is taking more and more space in the medical industry. This manufacturing technique is actually helping surgeons and doctors in their daily job. That is why we can say that 3D printing is helping to save lives on different levels.

Applications of additive manufacturing in the medical sector are numerous. 3D printing is making it possible to create perfectly adapted devices: from casts to prosthetics. But it also becomes possible to make implants, adapted tools for surgeons, and to print a 3D model to prepare a complex surgery. Indeed, it is becoming common in hospitals to 3D print models of kidneys or hearts and prepare some complex surgeries.

It is possible to print living tissues

Here is an outstanding material that is now 3D printable: Living tissue, or organ parts. It is a kind of part of the new experiments made in the medical industry to save lives.

3D Bioprinting allows creating various tissue structures, such as kidney tissue or skin tissue. Even blood vessels and bones are now becoming 3D printable using this technology. This is definitely offering new possibilities in terms of tissue engineering and regenerative medicine

Another benefit of this great bioprinting technology to create living tissues: it is a great way for medical researchers to make laboratory tests. For example, instead of testing on animals, it is becoming possible to test directly on human tissue or organs as these prints have the exact same properties and reactions.

3D printing is not only possible on earth

Additive manufacturing is not only dedicated to use on earth, and astronauts know it! This game-changing technology is offering great advantages in space, but which ones? 3D printing in space can be used for several projects from creating adapted tools to a 3D printed habitat to live on Mars, or on the Moon. Additive manufacturing and 3D printing without gravity are actually offering brand new possibilities.

You can lower your costs using 3D printing

People often see 3D printing as an expensive manufacturing technique, but it could actually help you lower your costs by accelerating your product development. As you know, in business, time is money. Using additive manufacturing is a great way to reduce costs and save time. It can help you with prototyping as it is faster and cheaper than many traditional processes. You only need to create a 3D model of your idea to print it.

3D printing can help to build houses

Additive manufacturing is also helping to build at an architectural scale! The first big advantage of this manufacturing technique for architecture is that it saves time. 3D Printing in the construction industry means reduced production time. Indeed, machines themselves are very fast, some of them are capable of manufacturing a 600 to 800-square-foot (55 to 75-square-meters) home in just 24 hours.

Additive manufacturing is really seen as a new way to create affordable housing. This new construction method can be used for social housing, but also to face the housing shortage in developing countries. But this technology actually offers possibilities for a large variety of architectural projects and buildings.

Are you ready to live inside a 3D printed home?

You can wear 3D printed parts

Clothes, shoes, jewelry, bags, glasses, watches, all of these elements can be 3D printed! Indeed 3D printed fashion is now a real thing.

Additive manufacturing is widely used by sneaker brands: Nike, Adidas, New Balance, or Reebok to name a few, major brands have tried it out with varying degrees of success. 3D printed glasses are also becoming a big thing. In the eyewear industry, this technology has been used more and more to create 3D printed glasses since it opens a broad range of possibilities to create 3D printed glasses frames totally custom-made.

Optimization of production processes, cost optimization (storage with on-demand printing, manufacturing as there are no material scraps, but also for prototyping …), customization possibilities or creation of complex shapes… 3D printing opens new creative fields for the fashion industry.

3D printing can improve your tooling process

When talking about the benefits of 3D technology, improving a tooling process is certainly not the first that comes to our mind. If your manufacturing process can be improved by a better prototyping or production process thanks to 3D printing, that is not all. Additive manufacturing can help you create tools perfectly adapted to your work.

This technology allows customizations. Surgeons, doctors, are more and more making the most of this technology to create tools adapted to their job, making them more convenient for their use. We had an example on our blog with Marc Soubeyrand. This surgeon is using 3D printing to create his own tools with plastic materials for orthopedic surgeries!

3D printing tools can also be a great way for your business to save money. For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

3D printing might be part of your favorite movie

A lot of movies now have 3D printed parts in it, the film industry is obviously making the most of all the advantages of additive manufacturing! It can be used to work on the designs of monsters or creatures or to directly manufacture props. You might not know it, but Iron Man’s suit is 3D printed, stormtroopers in Star Wars movies also have some 3D printed parts. 3D printing can also be used in animation film to create 3D printed parts and universes.

In the Black Panther movie, 3D printing actually helped to push the limits of design to create Queen Ramonda’s look, by mixing traditional African culture together with new-age technology.

Marvel Studios’ BLACK PANTHER to R: Shuri (Letitia Wright) and Ramonda (Angela Bassett)Ph: Matt Kennedy©Marvel Studios 2018

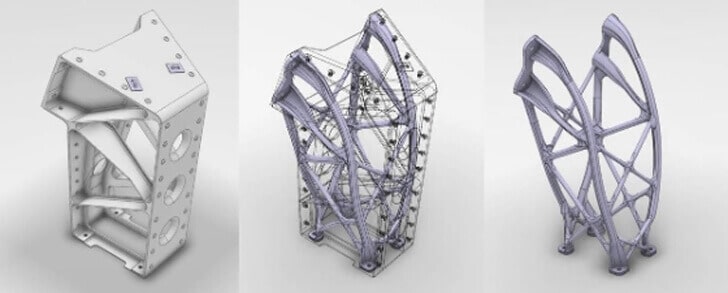

Mass-production is possible with additive manufacturing

Additive manufacturing can be used for production, yes, we just saw that. But do you know that this technology can go even further and can also be used for mass-production? Mass producing goods is no longer a problem for 3D technology, and mass manufacturers are already using it. Companies such as Airbus are seeing the full potential of additive manufacturing to mass-produce parts!

You can 3D print food

Do you know that even food is 3D printable? It is already possible to 3D print steaks and vegan steaks. Moreover, the chocolate 3D printer will be the perfect investment for your next Easter.

Regarding meat 3D printing, Giuseppe Scionti, an Italian bioengineer worked on some bioprinting projects, such as creating synthetic tissues, like artificial corneas and 3D printed artificial skin. As you can imagine, working on regenerative medicine can definitely help to recreate meat products. This Italian scientist is on his way to find a way to produce meat and help reduce greenhouse gas emissions from livestock, at the same time.

Chocolate 3D printing is also becoming quite interesting for chefs working in pastry. 3D printers are actually helping them create chocolate designs that are complicated to achieve only using hands.

Actually, you can 3D print anything… even a 3D printer

Everything is 3D printable, even 3D printers! You could 3D print a 3D printer by yourself. Some self-replicating 3D printers are already available on the market. But, these types of 3D printers can’t do the whole job themselves, there is still some assembly that can’t be done automatically. And there are still a few parts of a 3D printer that can’t be 3D printed, such as electronic components. So you can 3D print a 3D printer, but not totally for now.

This also stands for plastic 3D printing only. Other types of 3D printers such as metal 3D printers, a liquid resin or ceramic 3D printing can’t be 3D printed!

The first self-replicating 3D printer was invented by Dr. Adrian Bowyer through the RepRap project and was unveiled in 2008.

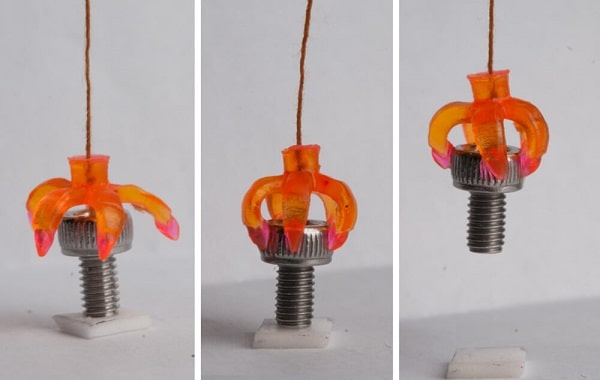

4D printing is on its way!

You read it right. 4D printing technology might be the next revolution. But what is 4D printing exactly, how is this different from 3D printing? 4D Printing is referred to as 3D printing transforming over time. For these objects, a fourth dimension is added: time. The big breakthrough about 4D printing over 3D printing technology is its ability to change shape over time.

Are you ready to get 4D printed projects?

Applications of 3D printing are numerous, as you can see. Have you discovered some interesting 3D printing facts in this blog post? Share your discoveries with us. Are you ready to use 3D printing for your own projects?

Try to upload your 3D file on our online 3D printing service and get your 3D objects in a few days. As we just saw, this technology could help you improve both prototyping and production processes, but could also help you go through brand new challenges.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook